Auxiliary steam device

A technology of auxiliary steam and auxiliary steam header, applied in the field of nuclear power, can solve problems such as inability to provide steam in time, avoid dynamic and static friction and the risk of large shaft bending, and ensure the gas supply demand.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

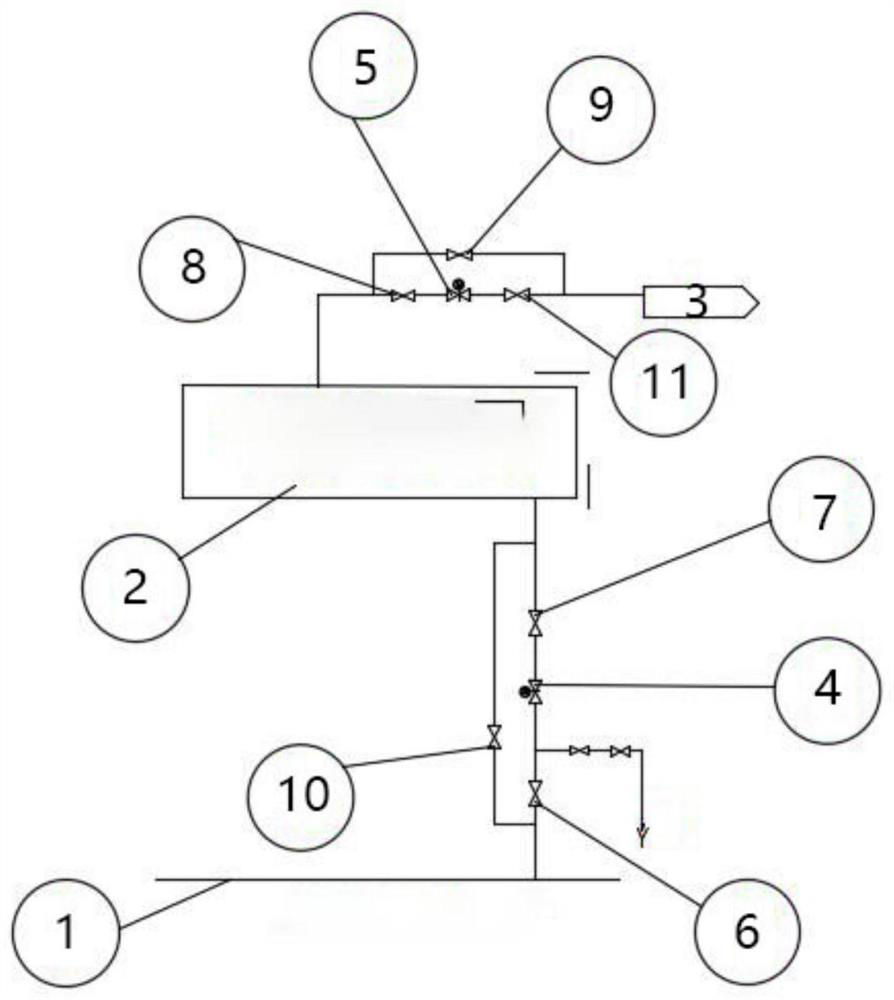

[0042] This embodiment provides an auxiliary steam device, such as figure 1 As shown, it includes: an auxiliary steam mechanism 1 , a heating mechanism 2 , a shaft sealing system 3 , a first isolation device 4 and a second isolation device 5 . Wherein, the auxiliary steam mechanism 1 is connected to the heating mechanism 2 through a pipeline; the first isolation device 4 is arranged between the auxiliary steam mechanism 1 and the heating mechanism 2, and is used to isolate the auxiliary steam mechanism 1 from the heating mechanism 2 , forming different spaces; the heating mechanism 2 is connected to the shaft sealing system 3 through pipes; the second isolation device 5 is arranged between the heating mechanism 2 and the shaft sealing system 3, and is used to connect the heating mechanism 2 and the shaft sealing The system 3 is isolated to form different spaces; the auxiliary steam mechanism 1, the heating mechanism 2, the shaft sealing system 3, the first isolation device 4 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com