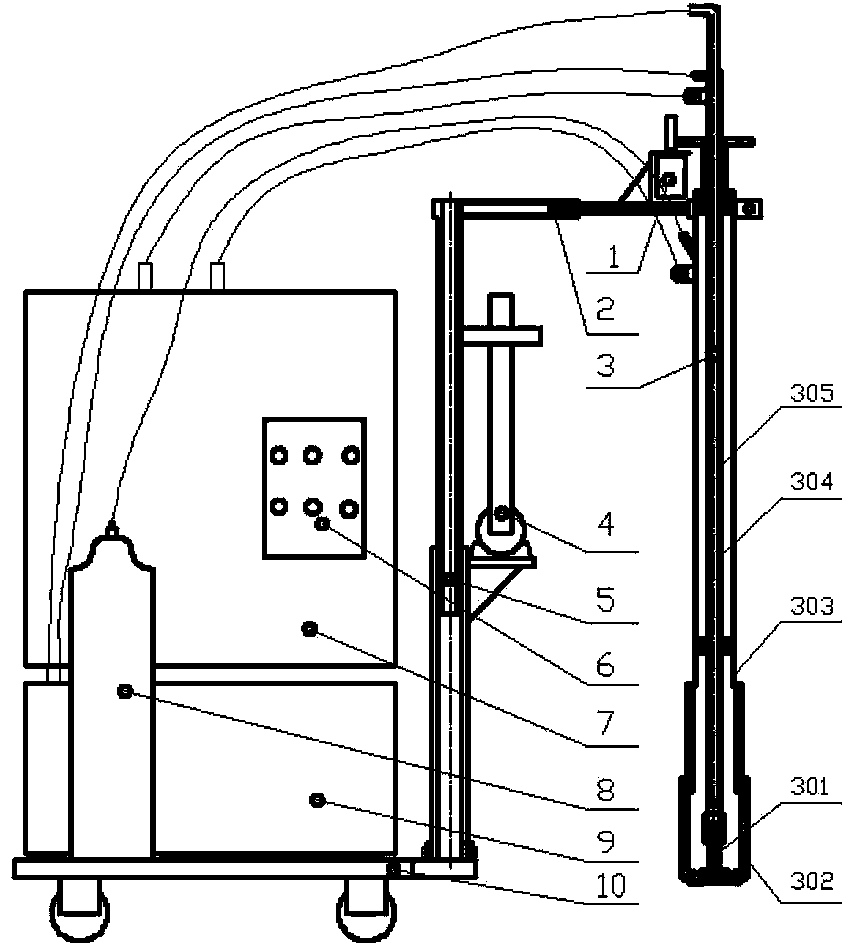

Plasma submerged arc heating device for steel ingot risers of 5-600 tons

A technology of submerged arc heating and plasma, which is applied in the field of steel ingot preparation, can solve the problems of small riser heat capacity, unsmooth feeding channel, and large impact of metal liquid surface, etc., and achieves reduced cutting volume, improved utilization rate, and convenient transportation. cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

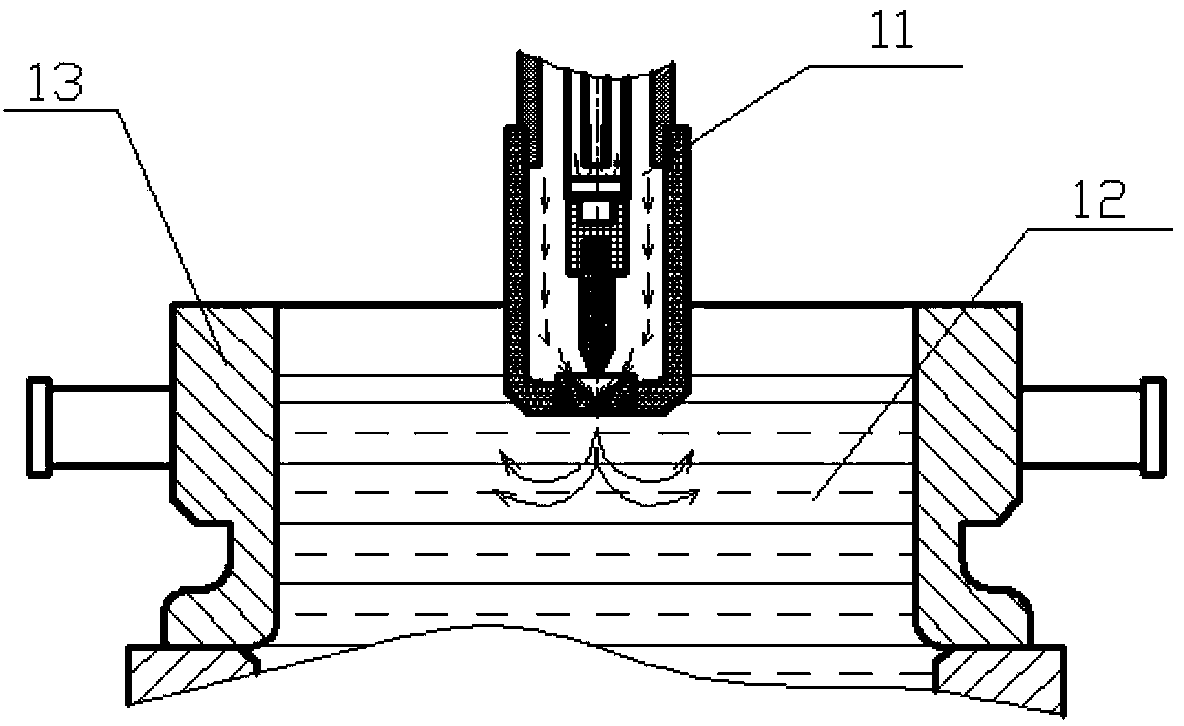

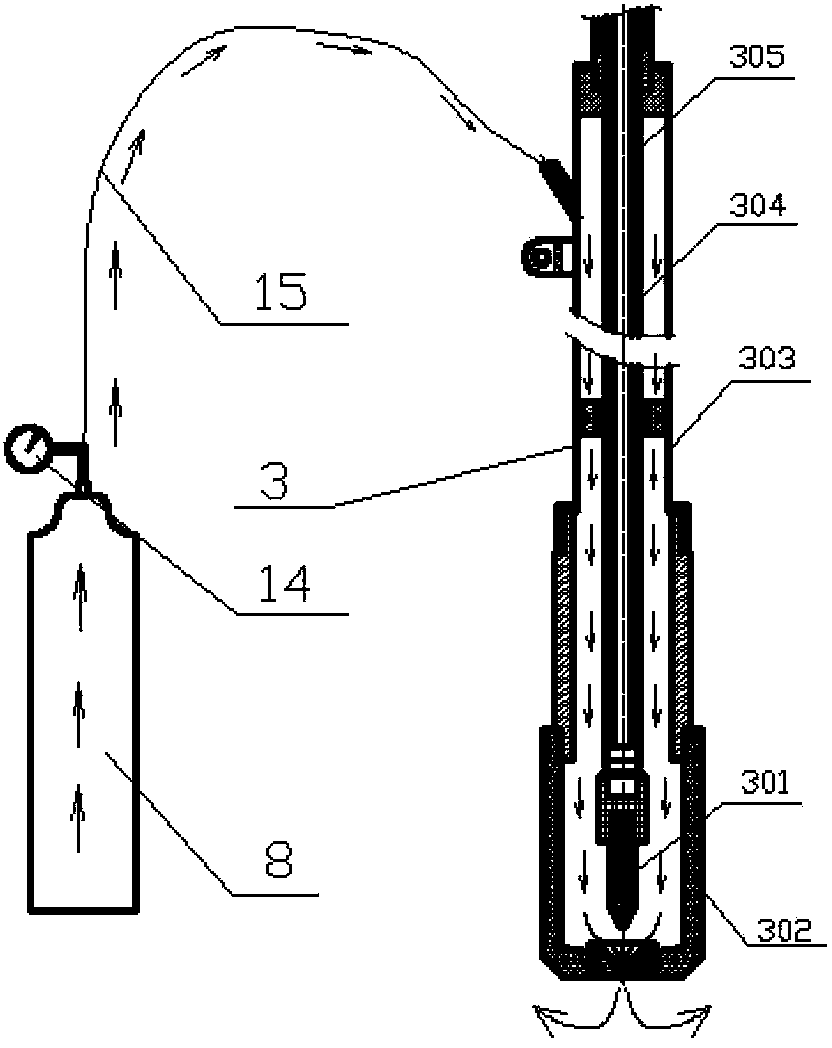

[0054] Such as figure 2 As shown, the plasma submerged arc heating device with the riser of the large steel ingot was used for trial production of 5.6 tons of large steel ingots, the material was 42CrMo, the filling time was 19min, and the pouring temperature was 1530°C. Prepare steel ingot molds, risers and gating systems according to the process regulations, and simultaneously smelt molten steel, and the temperature of molten steel is controlled at a low superheat. Before pouring, clean the ingot cavity and prepare the insulation covering agent. use The small sprue flow steel brick is poured, and the molten steel flow rate is controlled at the same time. The pouring method is slow pouring at the beginning, fast pouring in the middle section, forging of the riser and slow pouring. After the molten steel is poured, the riser is heated immediately, and after heating for 10 minutes, the heating is stopped, and the thermal insulation covering agent is added. Finally, take of...

Embodiment 2

[0056] Such as figure 2 As shown, the plasma submerged arc heating device with the riser of the large steel ingot is used for trial production of 5.5 tons of large steel ingots, the material is 42CrMo, the filling time is 18min, and the pouring temperature is 1550°C. Prepare steel ingot molds, risers and gating systems according to the process regulations, and simultaneously smelt molten steel, and the temperature of molten steel is controlled at a low superheat. Before pouring, clean the ingot cavity and prepare the insulation covering agent. use The small sprue flow steel brick is poured, and the molten steel flow rate is controlled at the same time. The pouring method is slow pouring at the beginning, fast pouring in the middle section, forging of the riser and slow pouring. After the molten steel is poured, the riser is heated immediately, and after 20 minutes of heating, the heating is stopped and the thermal insulation covering agent is added. Finally, take off the i...

Embodiment 3

[0058] Such as figure 2 As shown, the plasma submerged arc heating device with the riser of the large steel ingot was used for trial production of 5.8 tons of large steel ingots, the material was 42CrMo, the filling time was 20min, and the pouring temperature was 1580°C. Prepare steel ingot molds, risers and gating systems according to the process regulations, and simultaneously smelt molten steel, and the temperature of molten steel is controlled at a low superheat. Before pouring, clean the ingot cavity and prepare the insulation covering agent. use The small sprue flow steel brick is poured, and the molten steel flow rate is controlled at the same time. The pouring method is slow pouring at the beginning, fast pouring in the middle section, forging of the riser and slow pouring. After the pouring of molten steel is completed, the riser is heated immediately, and after heating for 30 minutes, the heating is stopped and the thermal insulation covering agent is added. Fin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com