Novel high-strength rescue steel sleeper and cushion block bearing combination and rapid stacking method

A high-strength, block technology, applied in the direction of supporting machines, engine frames, mechanical equipment, etc., can solve the problems of increasing labor intensity, affecting rescue efficiency, and being difficult to carry, and improving rescue efficiency and rescue capabilities. Combination Flexible, clutter-proof effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

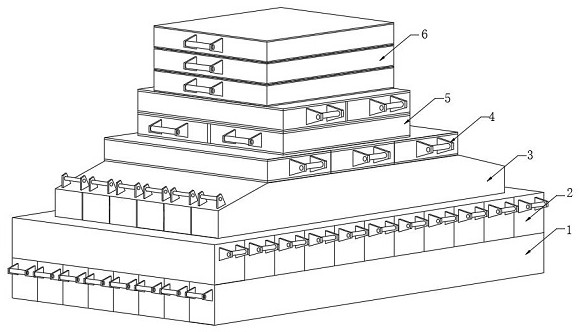

[0042] see Figure 7-Figure 15 , in the embodiment of the present invention, the upper block 6, the short horizontal block 5, the long horizontal block 4 and the long sleeper block 3 are all made of high-strength thin steel plates through a special welding process to form a hollow sealed body structure, and the interior is uniformly arranged A group of long and short rib boards, with positioning grooves on the long and short rib boards, are interlaced with each other to separate the pads into a honeycomb structure. The bottom steel sleeper 1, the upper steel sleeper 2, the long sleeper pad 3, the Handles are welded on both sides of the horizontal pad 4, the short horizontal pad 5 and the upper pad 6, which are used to manually lift the pad and the steel pillow; the use mode of the steel pillow and the pad depends on the scene rescue conditions and requirements , can be divided into standard stacking mode and flexible stacking mode;

[0043] Standard stacking working mode:

...

Embodiment 2

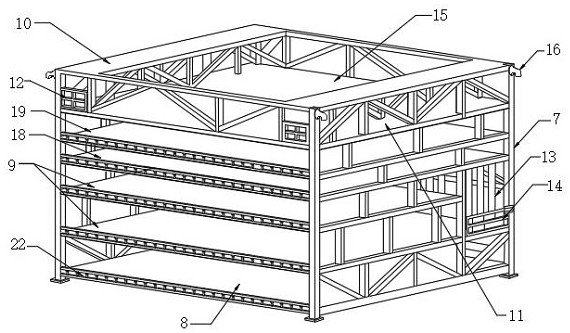

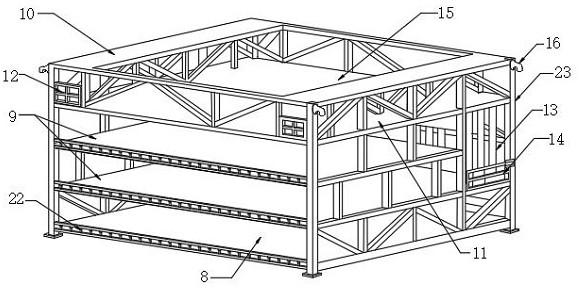

[0058] see Figure 2-Figure 6 , and embodiment 1 difference is: drawer-type integral hanging box one 7 and drawer-type integral hanging box two 23 are all made up of the first long sleeper cushion area 8, upper floor steel sleeper area 9, hanger 10, the second long sleeper cushion Area 11, the first door 12, the short horizontal block area 13 and the second baffle plate 14 are combined, the drawer-type overall hanging box one 7 and the drawer-type overall hanging box three 17 are provided with a long horizontal pad area 18 and an upper layer Pad block area 19, and upper layer pad block area 19 is arranged on the top of long horizontal pad area 18, drawer type integral hanging box one 7, drawer type integral hanging box two 23 upper ends are all provided with hollowed out area 15, drawer type integral hanging box three 17 The lower end surface is fixed with a limit frame 20 opposite to the hollow area 15, the drawer-type integral hanging box 1 7 and the drawer-type integral han...

Embodiment 3

[0061]The drawer-type overall hanging box is the lifting and storage equipment for steel sleepers and pads. In the non-rescue state, place the full steel sleeper and drawer-type overall hanging box 17 next to the electrical cabinet of the main tour car of the rescue train. The drawer type The integral hanging box 3 17 is placed above the drawer-type integral hanging box 1 7, and by manually turning the handle 2103, its snap ring 2104 is socketed on the lifting lugs 16 around the drawer-type integral hanging box 1 7, and the drawer-type integral hanging box 17 is fastened. Hanging box 1 7 is fastened to the drawer-type overall hanging box 3 17, and the drawer-type integral hanging box 2 23 is placed under the main traveling car hook of the rescue train. The first 7 places of the integral hanging box are hoisted to the second 23 of the integral hanging box of the drawer type, and the same is fixed by a quick locking mechanism, and then the integral hanging box 1 of the drawer typ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com