System and method for regulating physical parameter of real turbomachine system from physical setpoint parameter

A physical parameter, real-time system technology, applied in the direction of turbine/propulsion fuel delivery system, general control system, fuel control of turbine/propulsion device, etc., can solve unresolved agility defects and other problems, and achieve the effect of quick adjustment and response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

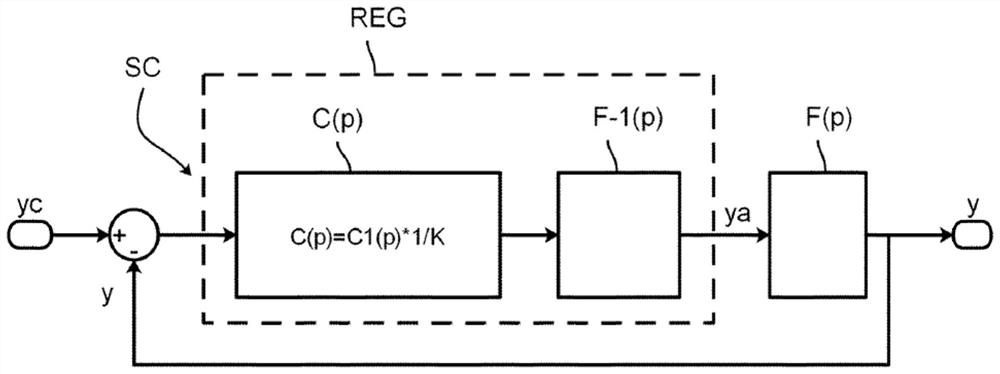

[0050] refer to figure 1 , which shows a correction system SC configured to determine a control parameter y as a function of a parameter setpoint yc. In this embodiment, the correction system SC implements an inverse model corrector. In other words, the correction system SC includes in sequence the corrector C(p), the inverse model F-1(p) and the real-time system F(p). The real-time system F(p) corresponds to the real-time system acting on the control parameter y. In practice, a real-time system F(p) implements several transfer functions. In essence, the real-time system F(p) changes over time (offset, wear, etc.) and does not correspond exactly to the parameter setting yc.

[0051] In the correction system SC implementing the inverse model corrector, the real-time system F(p) is assumed to be mathematically invertible to define the inverse model F -1 (p). According to this assumption, since F -1 (p)*F(p)=1, the correction system SC essentially depends on the corrector C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com