High-speed cross slot milling machine

A slot milling machine and cross technology, which is applied in the field of high-speed cross slot milling machines, can solve the problems of slow cutting speed of the workpiece and inability to cut cross-shaped slots on the surface of the workpiece.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

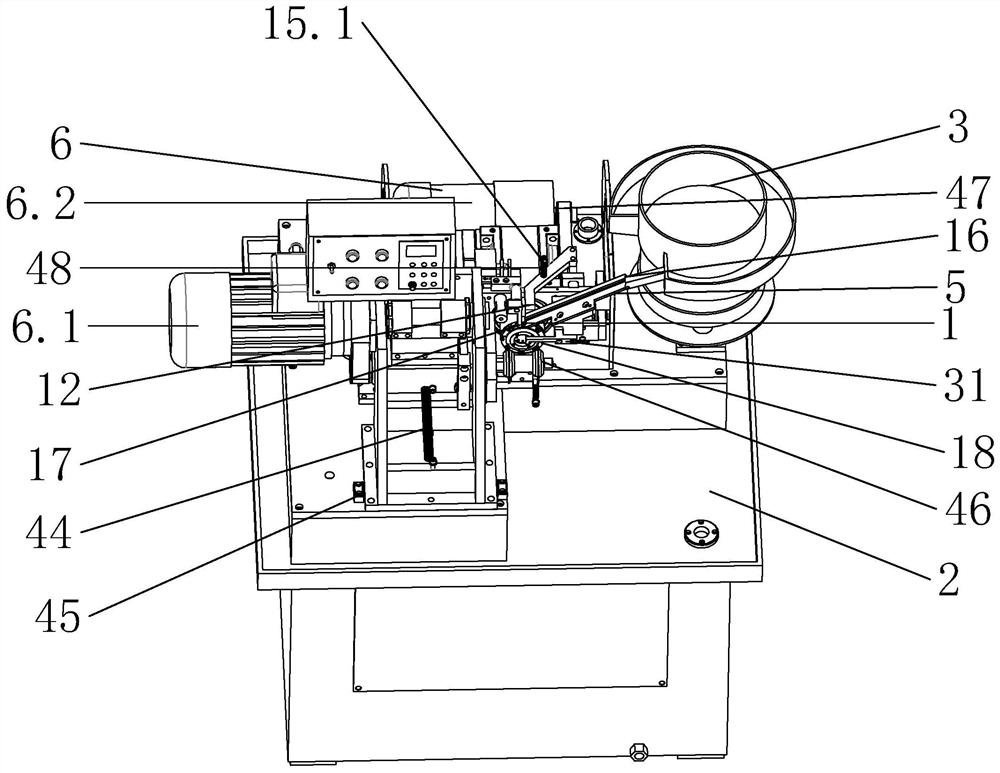

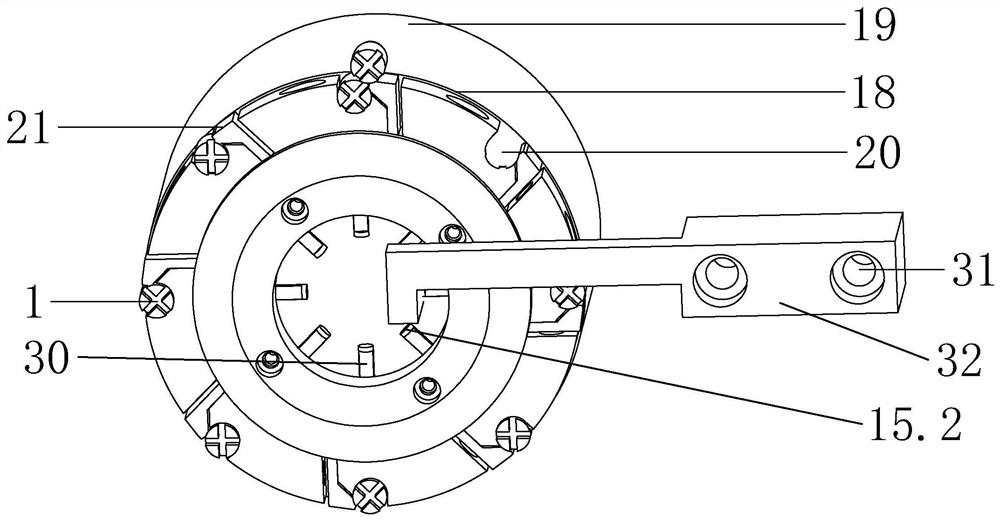

[0036] like figure 1 or figure 2As shown, a high-speed cross milling machine includes a frame 2, a feed structure 16 arranged above the frame 2, a clamping structure 18 arranged below the feed structure 16 and fixed on the frame 2, Milling cutter structure 46, discharge structure 31 close to the surface of clamping structure 18, linkage structure 47, reset structure 48; The seat 19 is provided with eight symmetrically distributed workpiece grooves 20, and beside the workpiece grooves 20 on the clamping disc seat 19, an elastic pressure sheet 21 for clamping the workpiece 1 is also provided. The feeding structure 16 includes a feeding guide rail 5 and It is used to push the workpiece 1 into the feed link 12 of the clamping structure 18. The lowermost end point of the feed link 12 is against the lowest point of the feed guide rail 5, and the contact between the feed link 12 and the feed guide rail 5 A clamping bracket 17 is provided, and the clamping bracket 17 is closely att...

specific Embodiment 2

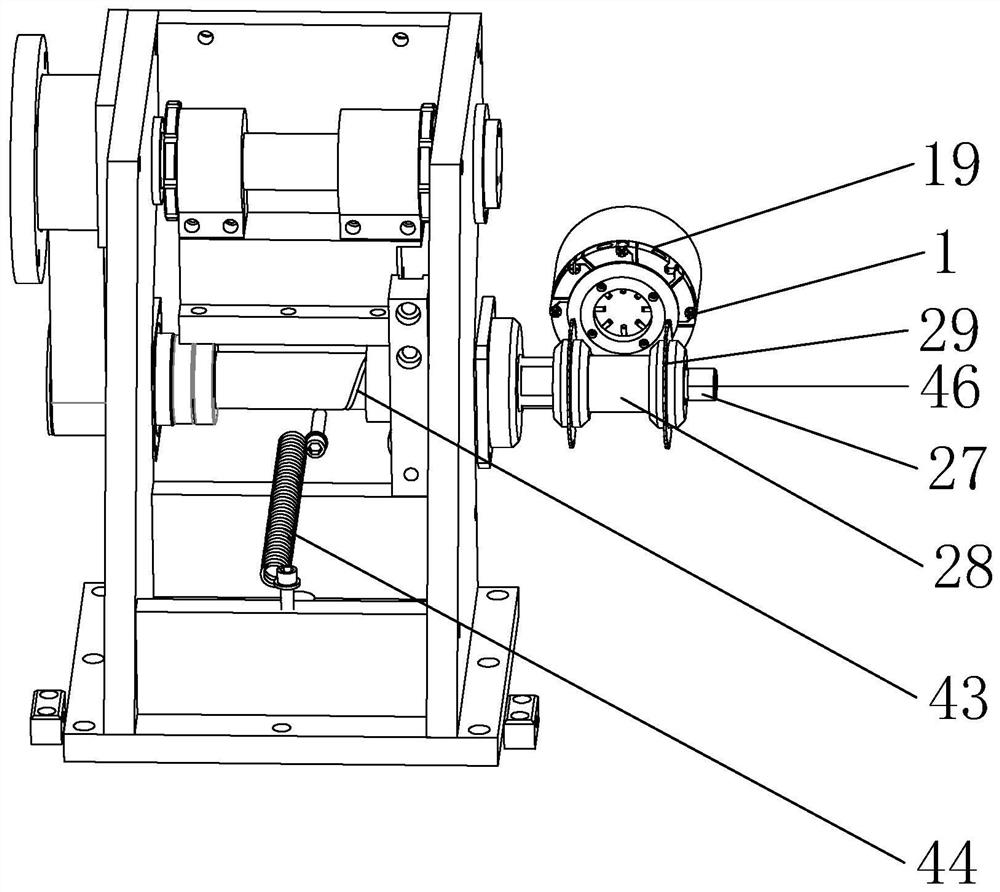

[0039] like image 3 or Figure 4 As shown, on the basis of Embodiment 1, the milling cutter structure 46 includes a milling cutter spindle 27 and a milling cutter 29, the milling cutter spindle 27 and the milling cutter 29 are connected by a milling cutter spacer 28, and a pair of milling cutter spindles are arranged on the same milling cutter spindle 27. The milling cutter 29 that is arranged horizontally, the distance between two milling cutters 29 is equal to the distance at the axis of the two workpieces 1 separated by 90 degrees on the clamping disc seat 19, and the milling cutter spindle 27 is provided with a lubricant for milling cutter spindle 27. The helical lubricating groove 43 is provided with oil seals at both ends of the lubricating groove 43 respectively. A high-speed cross milling machine also includes a driving structure 6. The driving structure 6 includes a motor 6.2 and a reduction motor 6.1. The motor 6.2 is used to drive the milling machine. The cutter s...

specific Embodiment 3

[0042] like Figure 5 As shown, on the basis of Embodiment 2, the discharge cam 10 is adapted to the needle roller bearing 33, the upper end of the needle roller bearing 33 is connected to the discharge structure 31, and the semicircle outside the discharge cam 10 is provided with a raised structure 34. The edge of the raised structure 34 gradually becomes higher in the middle, the distance between the needle roller bearing 33 and the discharge cam 10 is smaller than the highest point of the raised structure 34, and the discharged structure 31 includes a right-angled discharge plate 35 and a discharge ejector pin 32, The outside of the right-angle discharge plate 35 is connected to the discharge ejector pin 32, and the inboard of the right-angle discharge plate 35 is connected to the chute 36. The frame 2 is provided with a turbine box 38, and the turbine box 38 is fixedly connected with a screw for matching with the chute 36. The protruding bar 37, the chute 36 is slidably co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com