Large-current electromagnetic switch

An electromagnetic switch and high-current technology, applied in the field of high-current electromagnetic switches, can solve the problems of inaccurate sampling, complex structure, and insufficient sealing of the device, and achieve the effects of simplified structure, reasonable and compact device structure, and easy sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

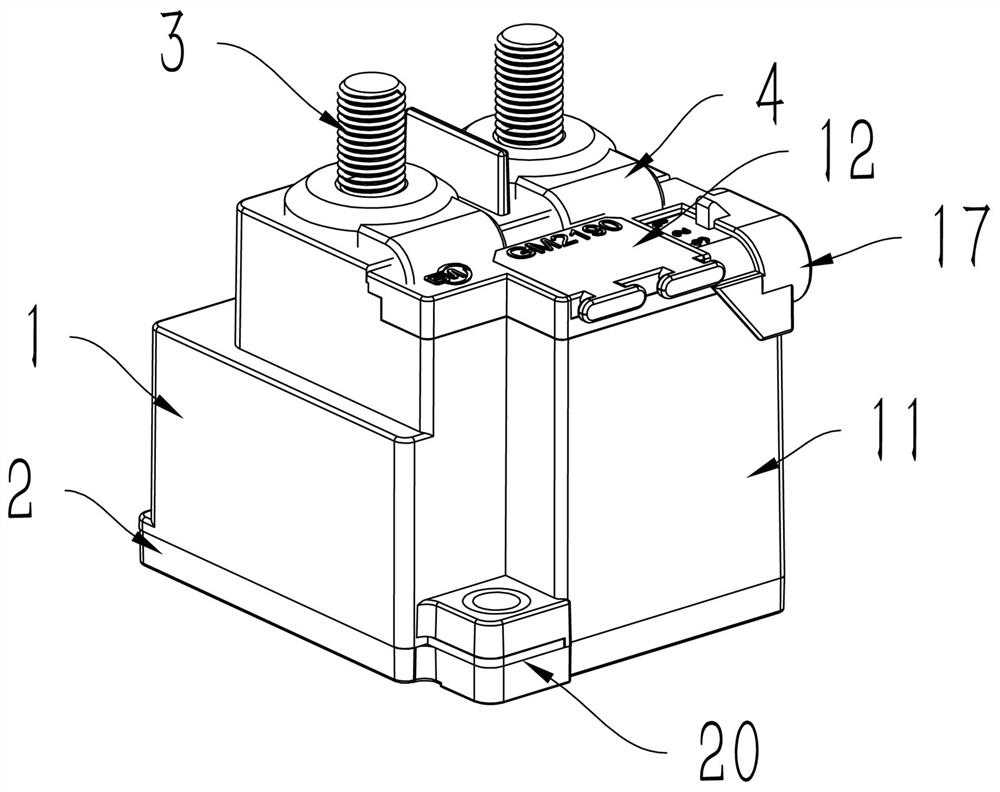

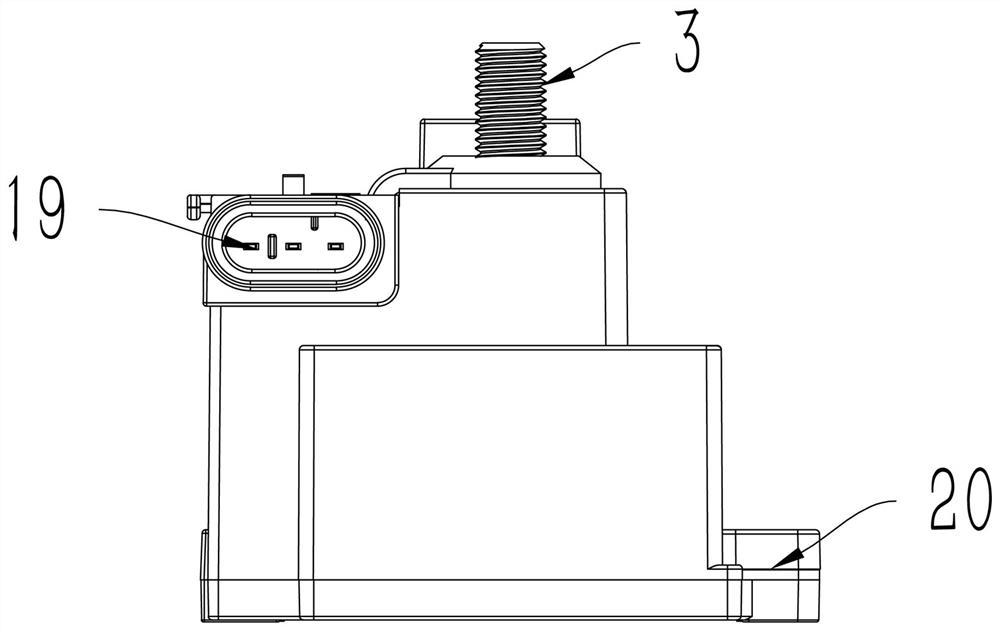

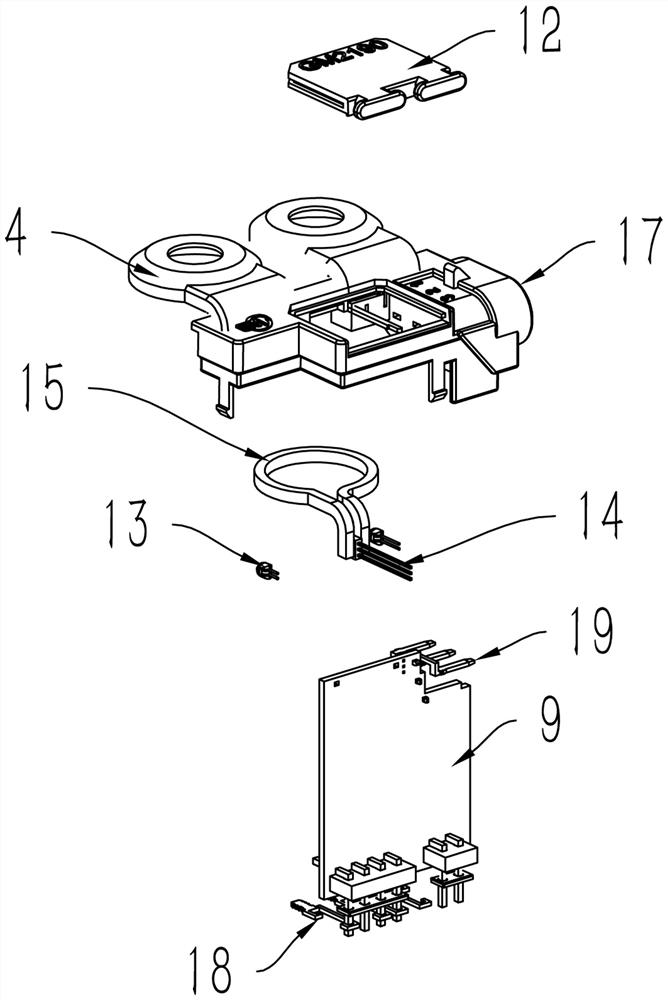

[0026] Embodiment 1: a kind of high-current electromagnetic switch, see Figure 1 to Figure 5 , including a housing 1, a coil 10 and a contact 6 are arranged inside the housing 1, the contact 6 includes a conductive horizontal plate and protrusions at both ends, a spring 7 is connected under the conductive horizontal plate, and an insulating Mounting plate 5. A terminal post 3 is installed on the top surface of the housing 1, and the terminal post 3 passes through the top surface of the housing 1 and is fixed thereon. When the switch is turned on, the contact 6 is in contact with the bottom of the terminal 3. At this time, the current flows from the terminal on the left through the conductive horizontal plate of the contact 6 to the terminal on the right to form a path. When the switch needs to be disconnected, Feed current into the coil 10 to generate a magnetic field, attract the contact 6 downward to separate the contact 6 from the terminal 3, and cut off the circuit.

[...

Embodiment 2

[0032] Example 2: see Image 6 , basically the same as Embodiment 1, the difference is that the circuit board can be designed as two pieces, respectively a control board 91 and a detection board 92, the control board 91 is arranged vertically and the detection board 92 can be arranged horizontally, which can be adjusted according to the actual situation Wiring.

Embodiment 3

[0033] Embodiment 3: On the basis of Embodiment 1, the copper sheet 4, current sampling ring 15, temperature sensor 13, and current sensor 14 are omitted, that is, all detection elements are removed, and only the main structure of the switch is retained, including the housing 1, The isolation compartment 11, the control circuit board 9, the pins 19, the cover plate 12, and the coil 10, contacts 7, and terminal posts 3 in the housing 1 can save costs, and use the isolation compartment to isolate the circuit board from the contacts in the housing Open to prevent the moisture in the glue injected on the circuit board from diffusing into the contact compartment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com