Noise reduction and heat dissipation motor

A technology of noise reduction and motor body, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve problems such as large noise, resonance between the base and the installation table, and achieve the effects of reducing resonance noise, avoiding resonance, and enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

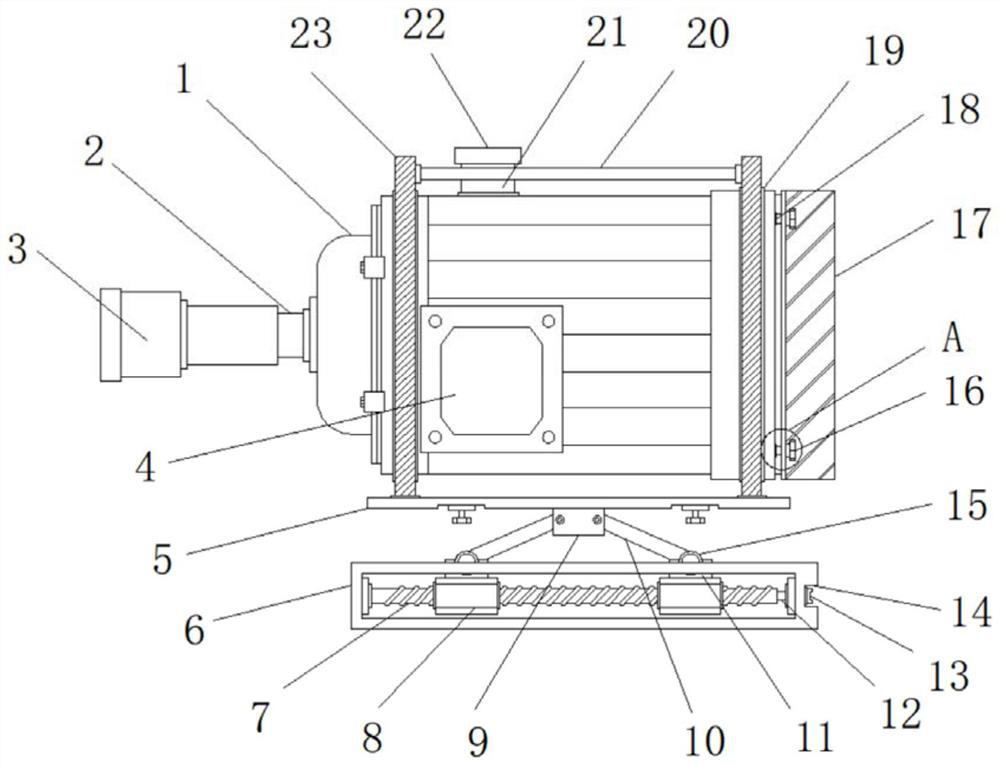

[0026] Example 1: See Figure 1-6 , a noise reduction, heat dissipation motor, including a motor body 1 and an output shaft 2, the output end of the motor body 1 is provided with an output shaft 2, one side of the output shaft 2 is equipped with a coupling 3, and the outside of the motor body 1 is provided with Two groups of protection rings 23, the bottom of protection ring 23 are fixedly connected with support platform 5, and the bottom of support platform 5 is provided with base 6, and the interior of base 6 is connected with threaded rod 7 movablely, and the external movable socket of threaded rod 7 has two Group screw block 8, end cover 17 is installed on the tail end of motor body 1, and the periphery of end cover 17 and motor body 1 cover all around are provided with corresponding screw hole 18, passes between end cover 17 and motor body 1 Screw holes 18 are fixedly connected with mounting bolts 16;

[0027] Specifically, such as figure 1 , figure 2 and Figure 5 A...

Embodiment 2

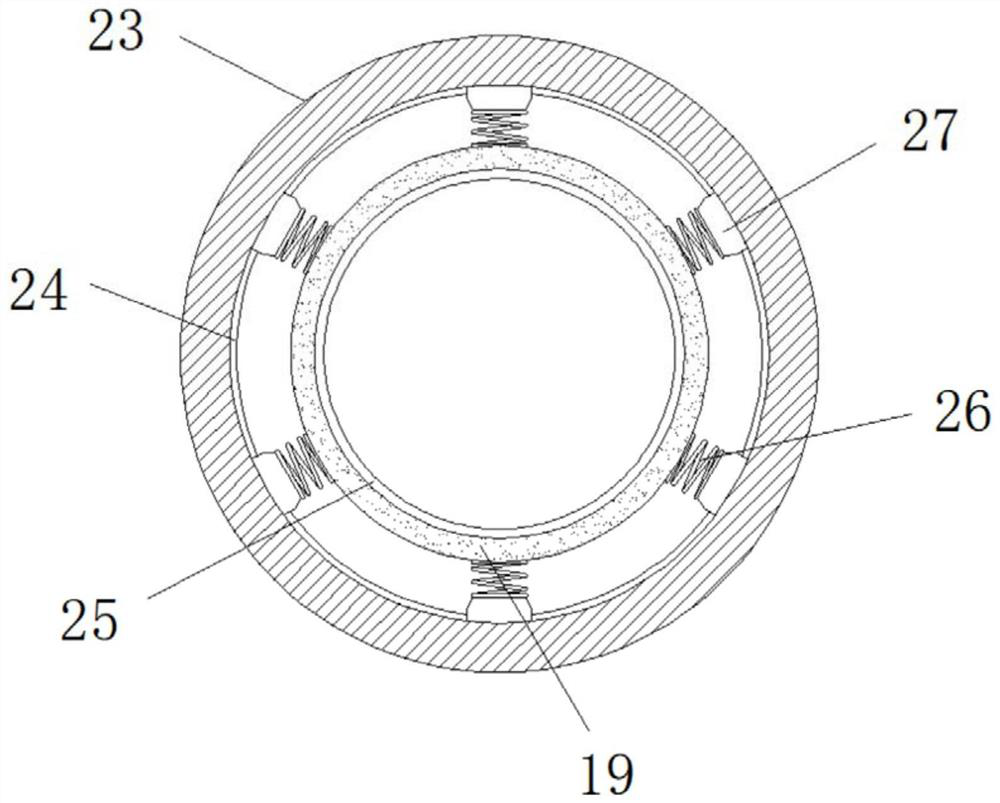

[0028] Embodiment 2: The inner wall of the protective ring 23 is provided with a movable groove 24, and the inside of the movable groove 24 is movably connected with six groups of shock absorbing blocks 27, and one end of the shock absorbing block 27 is fixedly connected with a spring 26, and the other end of the spring 26 is installed with a rubber Ring 19, the inner wall of the rubber ring 19 is bonded with a silicone gasket 25, the size of the protective ring 23 matches the motor body 1, the protective ring 23, the rubber ring 19 and the silicone gasket 25 are distributed in concentric circles, and the protective ring 23 is on the motor body 1. There are two sets of protection rods 20 fixed horizontally between the tops of the protection rings 23, a lubricating oil inlet 21 is arranged on the top of the motor body 1, and a sealing cover 22 is installed on the top of the lubricating oil inlet 21. The motor body 1 One end of is provided with an outlet box 4;

[0029] Specific...

Embodiment 3

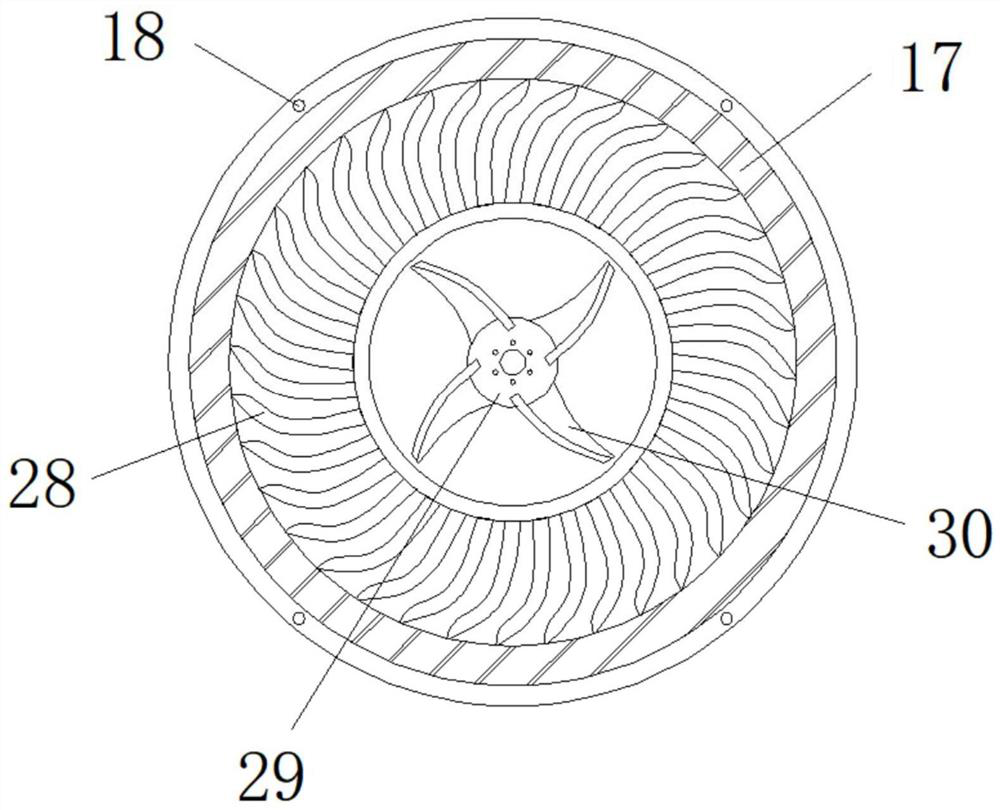

[0030]Embodiment 3: A radiator 29 is installed in the middle of the end cover 17, and four sets of fan blades 30 are installed on the outside of the radiator 29. The fan blades 30 are detachable, and multiple sets of cooling fins are distributed around the end cover 17. 28;

[0031] Specifically, such as figure 1 , image 3 , Figure 4 and Figure 6 As shown, a radiator 29 is installed in the end cover 17 at the tail end of the motor body 1, and the radiator 29 is provided with four sets of detachable fan blades 30, which are convenient for disassembly and maintenance. The air flow is exported to the outside of the end cover 17 through the heat dissipation fins 28. The heat dissipation fins 28 increase the heat exchange area and improve the heat dissipation efficiency, so that the high temperature heat inside the motor body 1 can be quickly dissipated to achieve a better heat dissipation effect and protect the interior. The stator and rotor components work efficiently and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com