Modulation method for improving tobacco leaf quality of Chinese prepared tobacco raw material of heated cigarettes by utilizing manual control

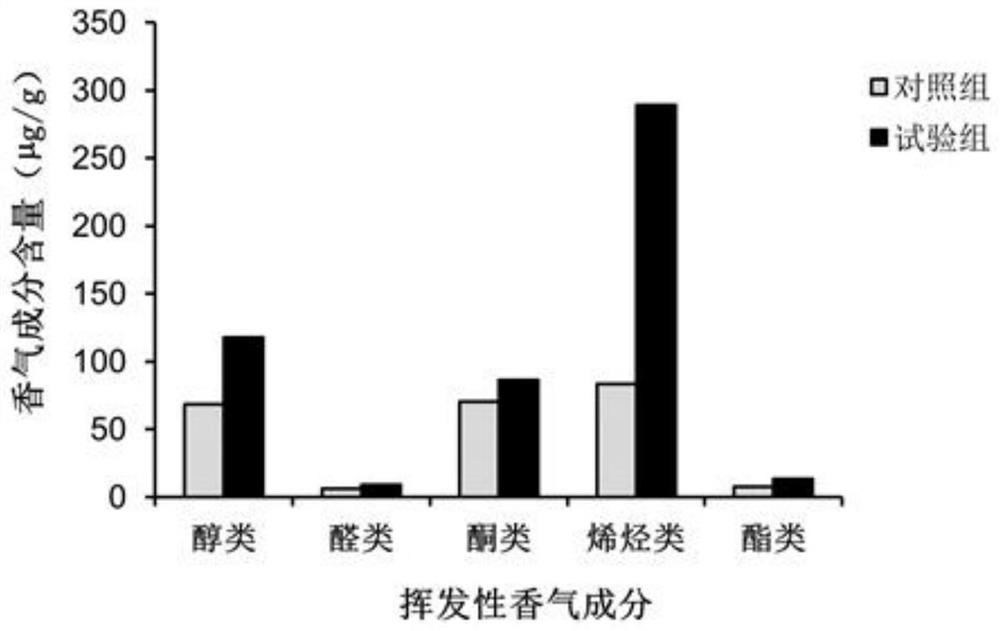

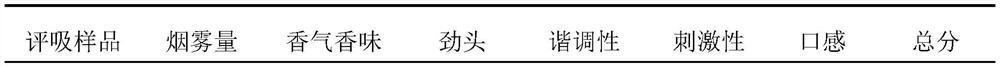

A technology of artificial control and modulation method, which is applied in the preparation of tobacco, cigars, tobacco, etc., which can solve the problem of affecting the stability and consistency of raw materials of heated cigarette tobacco leaves, uneven quality of tobacco leaf sensory evaluation, green and yellow slices of tobacco leaves Many problems, to achieve the effect of ensuring quality stability, improving sensory quality, and improving sensory quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] A preparation method for improving the quality of raw tobacco leaves of heated cigarette native tobacco by utilizing manual control provided by this embodiment includes the following steps:

[0029] (1) Hanging on the pole after harvesting the fresh tobacco leaves of suitable ripening soil: according to the suitable ripening requirements for the tobacco ribs to turn white, the leaf surface to be pale yellow and the leaf tips to curl downwards, the harvesting is carried out at the research and testing base of Hongta District, Yuxi City. In view of the suitable ripe fresh tobacco leaves grown in this test, the recovered fresh tobacco leaves were weaved on a 145cm pole with a string, with 140 pieces per pole.

[0030] (2) Shed installation: The tobacco leaves that have been woven into the poles are installed in a drying shed that can be heated, humidified, ventilated and shaded at a distance of about 30cm. 2 , the inner height of the drying shed is 380cm-400cm, the inner l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com