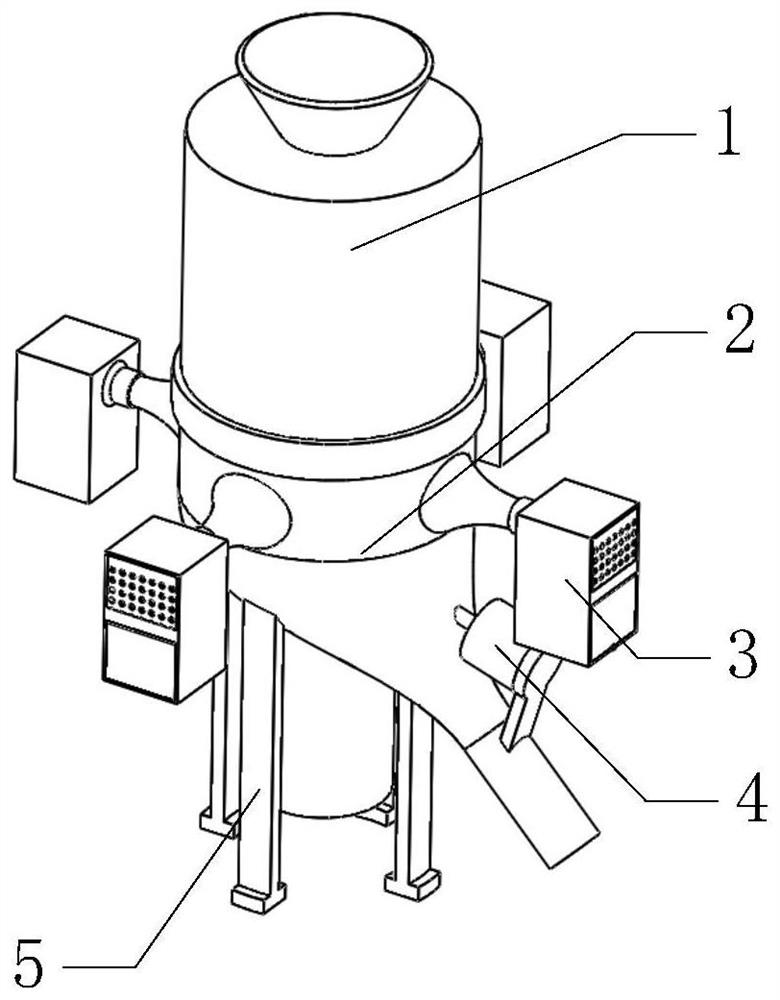

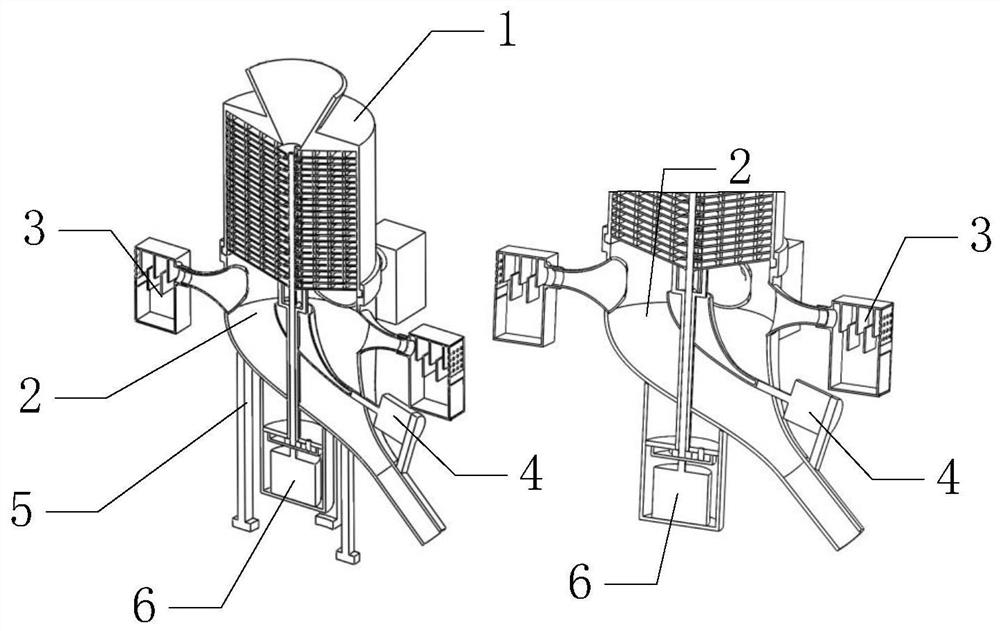

A kind of production equipment for grain, oil and rice milling

A technology for production equipment and grain and oil, applied in the field of production equipment for grain, oil and rice milling, can solve the problems of long residence time, low filling coefficient, fast processing speed, etc., and achieve the effects of increasing grinding volume, reducing friction and increasing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

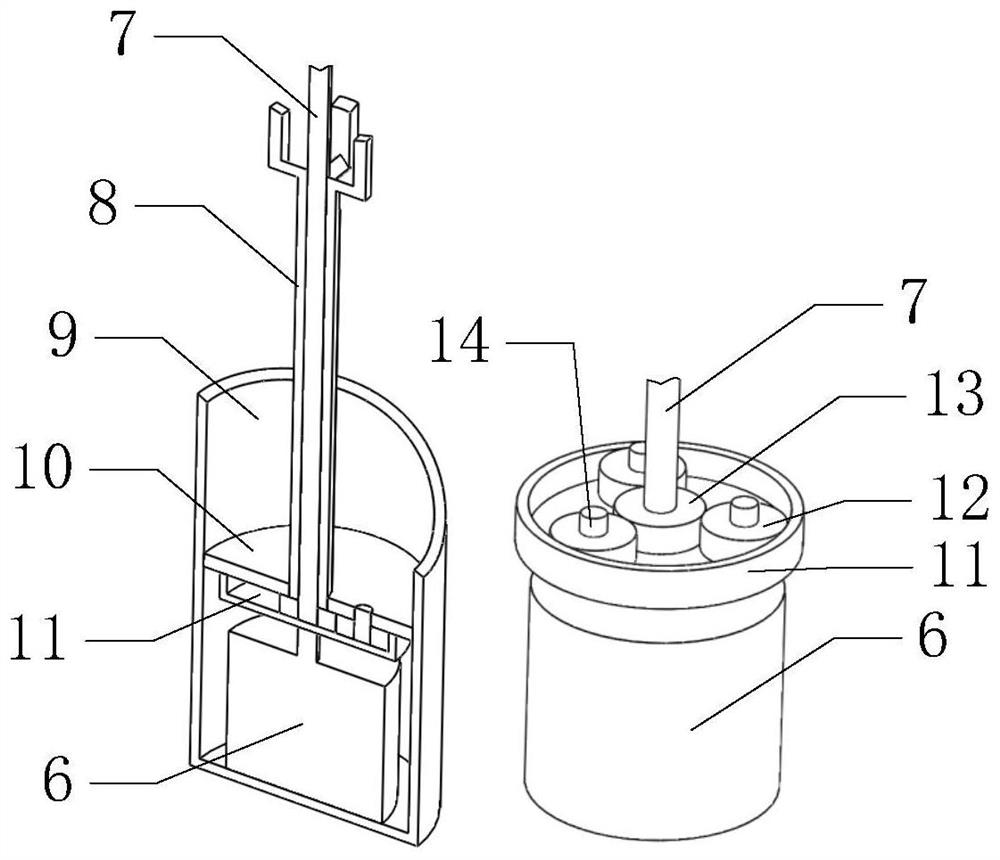

[0052] Embodiment: When using the equipment designed by the present invention, when grinding, the motor 6 and the air pump 4 are controlled to work, the motor 6 will drive the ring gear 11 to rotate, and the rotation of the ring gear 11 drives the installation shaft 7 to rotate, and the ring gear 11 rotates through the The three planetary gears 12 drive the sun gear 13 to rotate, and through the transmission of the three planetary gears 12, the rotation speed of the sun gear 13 is greater than the rotation speed of the ring gear 11 and the rotation direction of the sun gear 13 is opposite to the rotation direction of the ring gear 11; The rotation of the sun gear 13 drives the rotation of the transmission shaft 8; the rotation of the installation shaft 7 will drive the rotation of the first conical rotary disk 24 installed on it, and the rotation of the transmission shaft 8 drives the rotation of the second conical rotary disk 25 which is fixedly connected with the lowermost sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com