Method for repairing heavy metal cadmium farmland soil by using stabilized repairing material

A repair material and soil repair technology, applied in the field of repairing heavy metal cadmium farmland soil with stabilized repair materials, can solve the problems of increased ecological risk, poor consideration, and discounted treatment effects, so as to improve the ability of stabilized repair and enhance fixation ability, the effect of reducing immersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

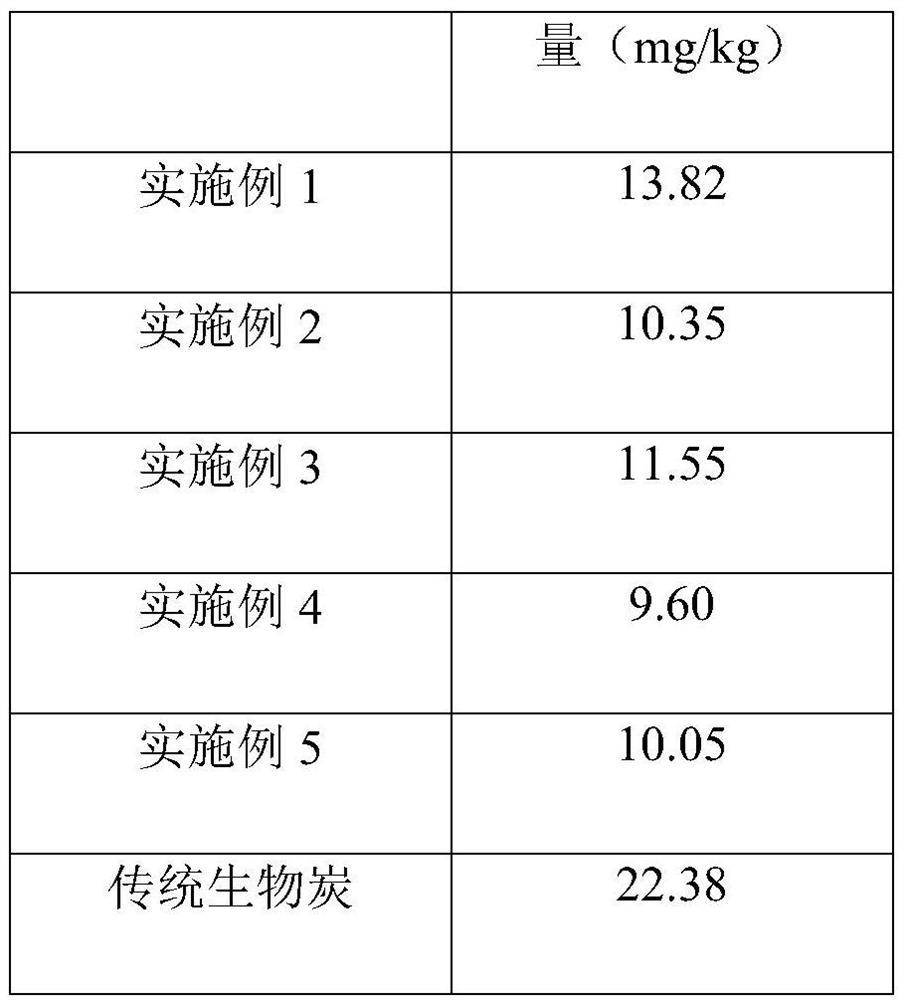

Embodiment 1

[0027] A method for repairing heavy metal cadmium farmland soil using stabilized repair materials, comprising the following steps:

[0028] S1: Soil Treatment

[0029] Preliminary screening of the soil to be repaired, separating stones with a particle size greater than 35mm from impurities in the soil to be repaired; crushing the obtained soil to be repaired, with a soil particle size of 2mm;

[0030] S2: Preparation of the first restoration material

[0031] Mix and stir biochar, calcium carbonate, and alkali sulfide in a mass ratio of 3:2:2, heat at 85°C for 3 hours, and keep stirring to obtain a mixture; then mix the obtained mixture with iron oxide in a mass ratio of 2:1 , after 20 minutes of magnetized grinding, heating in a water bath at 80°C for 60 minutes, and continuous stirring, to obtain the first repair material;

[0032] Wherein the particle diameter of biochar is 0.5mm, the particle diameter of calcium carbonate is 120nm, the particle diameter of alkali sulfide...

Embodiment 2

[0043] A method for repairing heavy metal cadmium farmland soil using stabilized repair materials, comprising the following steps:

[0044]S1: Soil Treatment

[0045] Preliminary screening of the soil to be repaired, separating stones with a particle size greater than 35mm from impurities in the soil to be repaired; crushing the obtained soil to be repaired, with a particle size of 1.8mm; and then sampling and analyzing the heavy metal content of the soil;

[0046] S2: Preparation of the first restoration material

[0047] Mix and stir biochar, calcium carbonate, and alkali sulfide in a mass ratio of 5:3:2, heat at 96°C for 4 hours, and keep stirring to obtain a mixture; then mix the obtained mixture with iron oxide in a mass ratio of 3:1 , after 25 minutes of magnetized grinding, heating in a water bath at 85°C for 90 minutes, and continuous stirring, to obtain the first repair material;

[0048] Wherein the particle size of biochar is 0.8mm, the particle size of calcium ca...

Embodiment 3

[0059] A method for repairing heavy metal cadmium farmland soil using stabilized repair materials, comprising the following steps:

[0060] S1: Soil Treatment

[0061] Preliminary screening of the soil to be repaired, separating stones with a particle size greater than 35mm from impurities in the soil to be repaired; crushing the obtained soil to be repaired, with a particle size of 1.8mm; and then sampling and analyzing the heavy metal content of the soil;

[0062] S2: Preparation of the first restoration material

[0063] Mix and stir biochar, calcium carbonate, and alkali sulfide in a mass ratio of 7:5:3, heat at 125°C for 8 hours, and keep stirring to obtain a mixture; then mix the obtained mixture with iron oxide in a mass ratio of 4:1 , after 30 minutes of magnetized grinding, heating in a water bath at 95°C for 120 minutes, and continuous stirring, to obtain the first repair material;

[0064] Wherein the particle diameter of biochar is 1.2mm, the particle diameter of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com