Automatic grinding device capable of replacing manual operation

A manual and automatic technology, applied in the direction of grinding drives, grinding machines, manufacturing tools, etc., can solve the problems of poor safety hazards in the working environment, difficulty in controlling the grinding accuracy, and high labor intensity, etc., to achieve improved grinding dimensional accuracy and small size , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings.

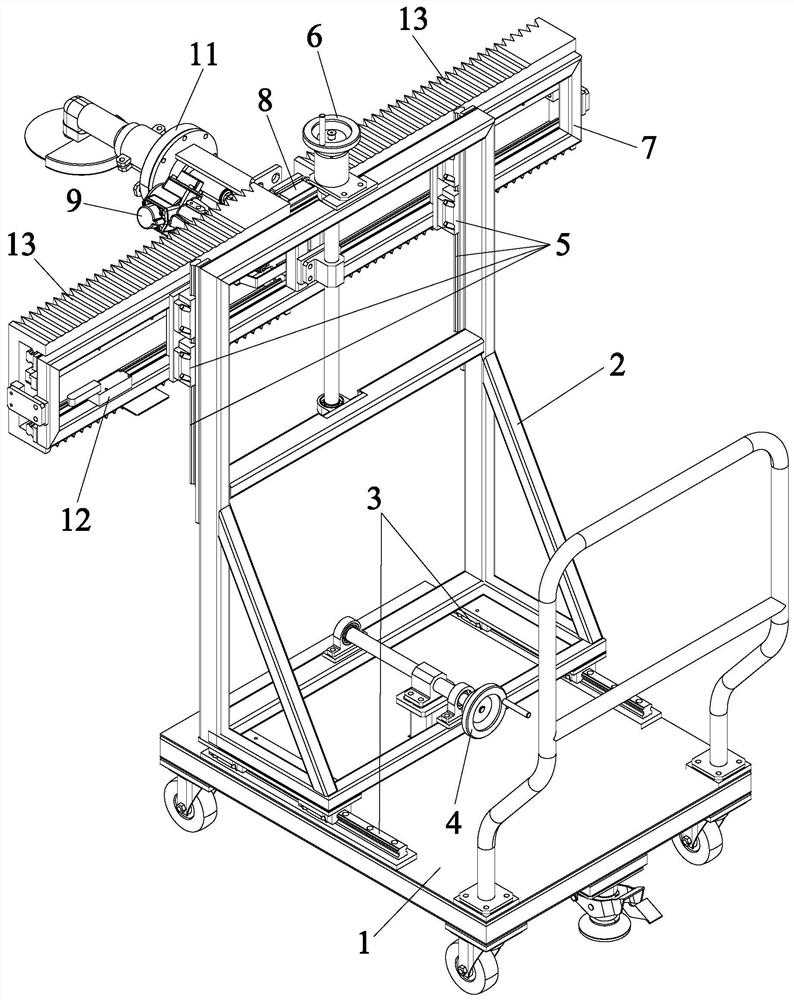

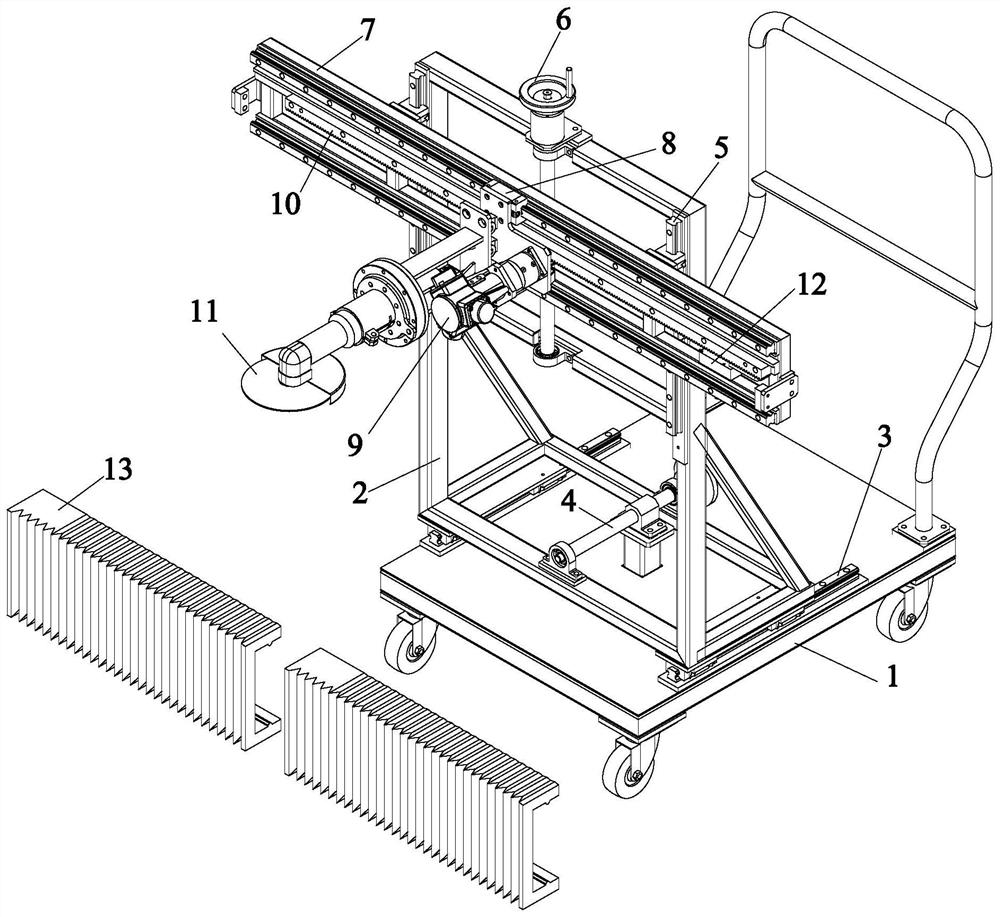

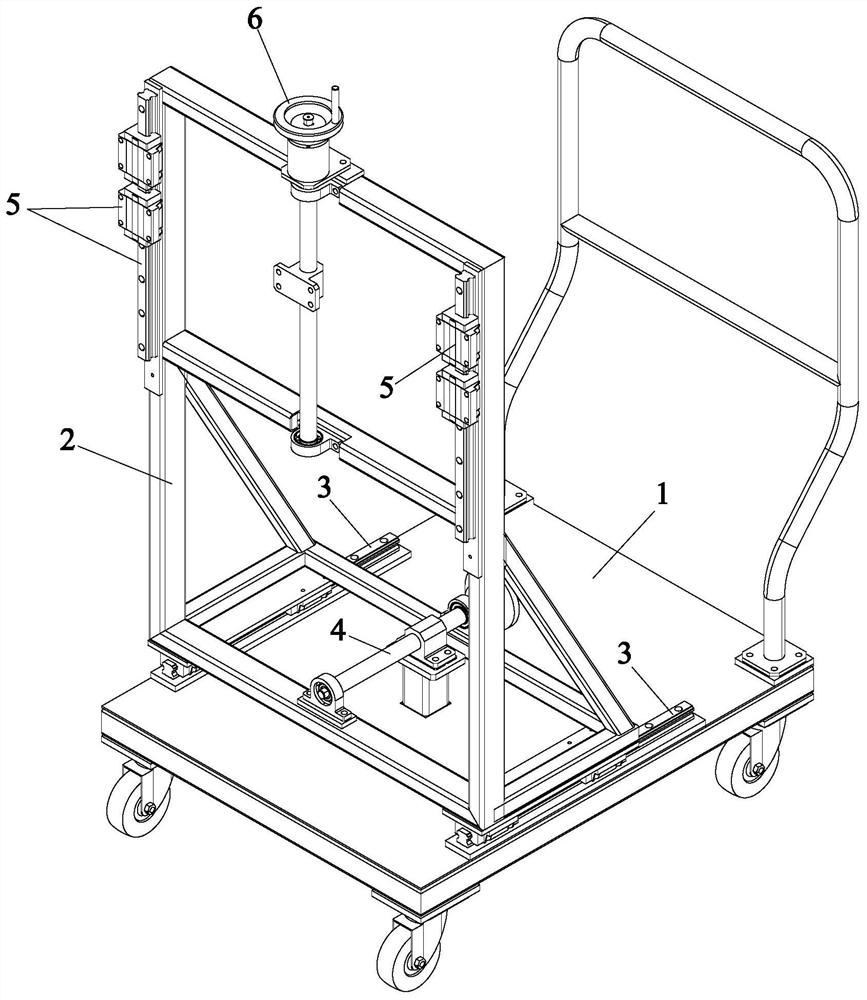

[0013] Such as Figure 1 to Figure 5 As shown, the present invention is an automatic grinding device instead of manual work, which includes a transport mechanism, a horizontal forward and backward movement mechanism, a vertical lifting mechanism, a horizontal left and right movement mechanism, a multi-angle grinding mechanism and a control system. The transportation mechanism is used to automatically polish The device is transported to the designated working position and locked and positioned; the horizontal forward and backward moving mechanism is fixedly connected to the transportation mechanism, which is used to move the multi-angle grinding mechanism forward and backward according to the operation requirements; the vertical lifting mechanism is fixedly connected to the horizontal forward and backward moving mechanism, It is used to move the multi-angle gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com