Flexographic printing machine high-quality printing method capable of controlling printing quality

A technology of flexographic printing machines and printing methods, which is applied to printing machines, general parts of printing machinery, printing, etc., can solve the problems of lack, different scales, product quality differences, etc., to achieve accurate identification, timely correction, Judging the precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] see Figure 1-5 , the present invention provides a technical solution:

[0055] A high-quality printing method for a flexographic printing machine capable of controlling printing quality, comprising the steps of:

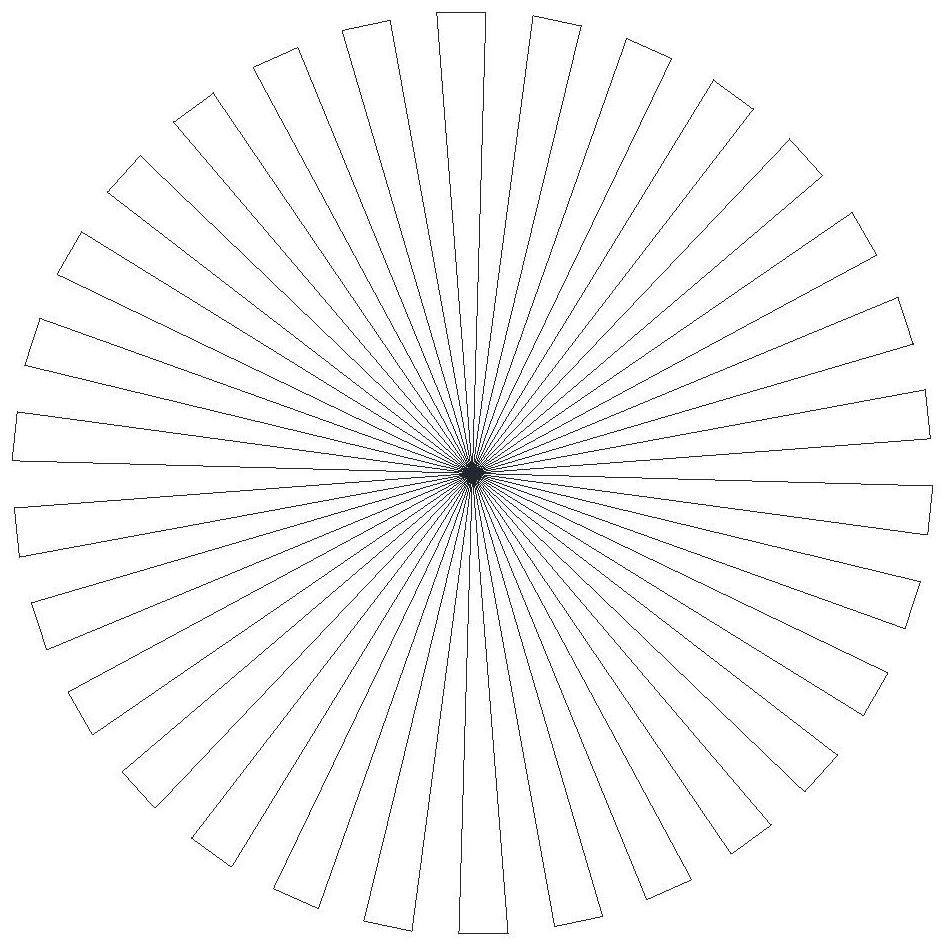

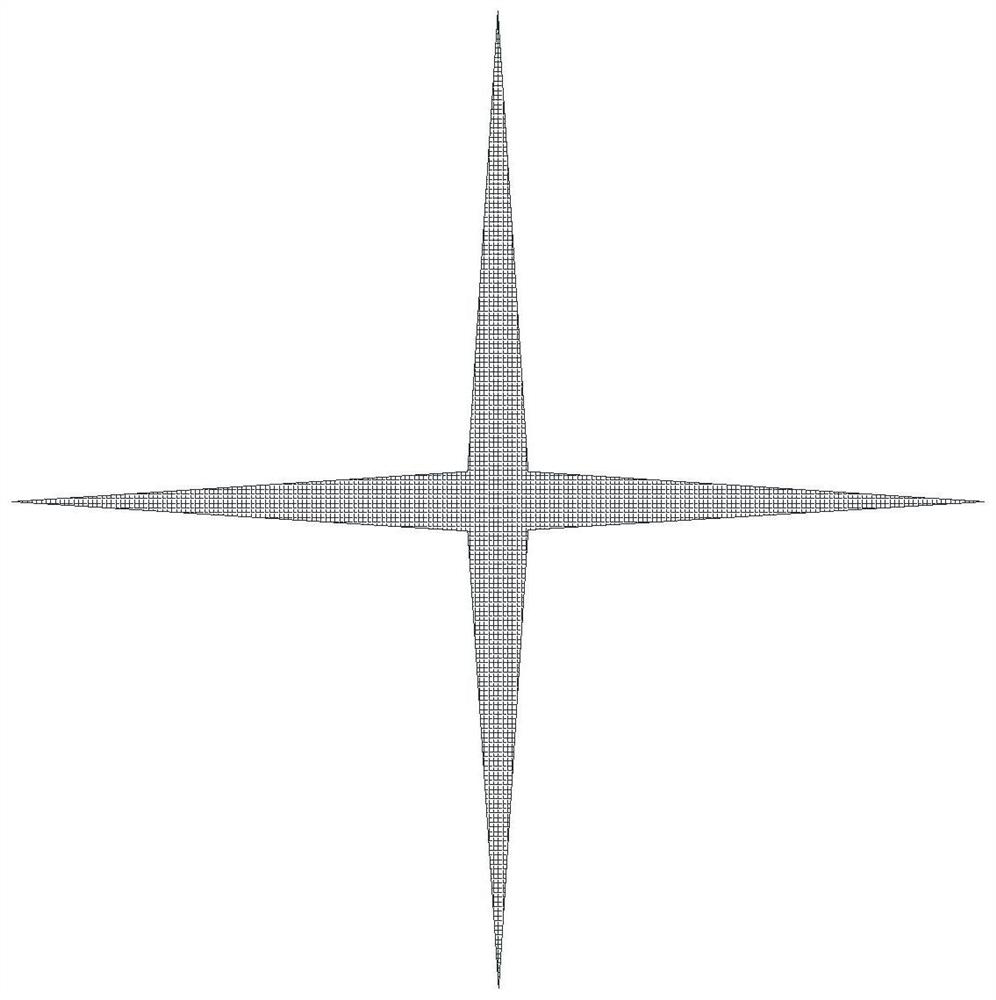

[0056] Step 1: Design the dot reproduction monitoring icon; and overprint the monitoring icon, and typesetting the dot reproduction monitoring icon; and the overprint monitoring icon and the graphics to be printed;

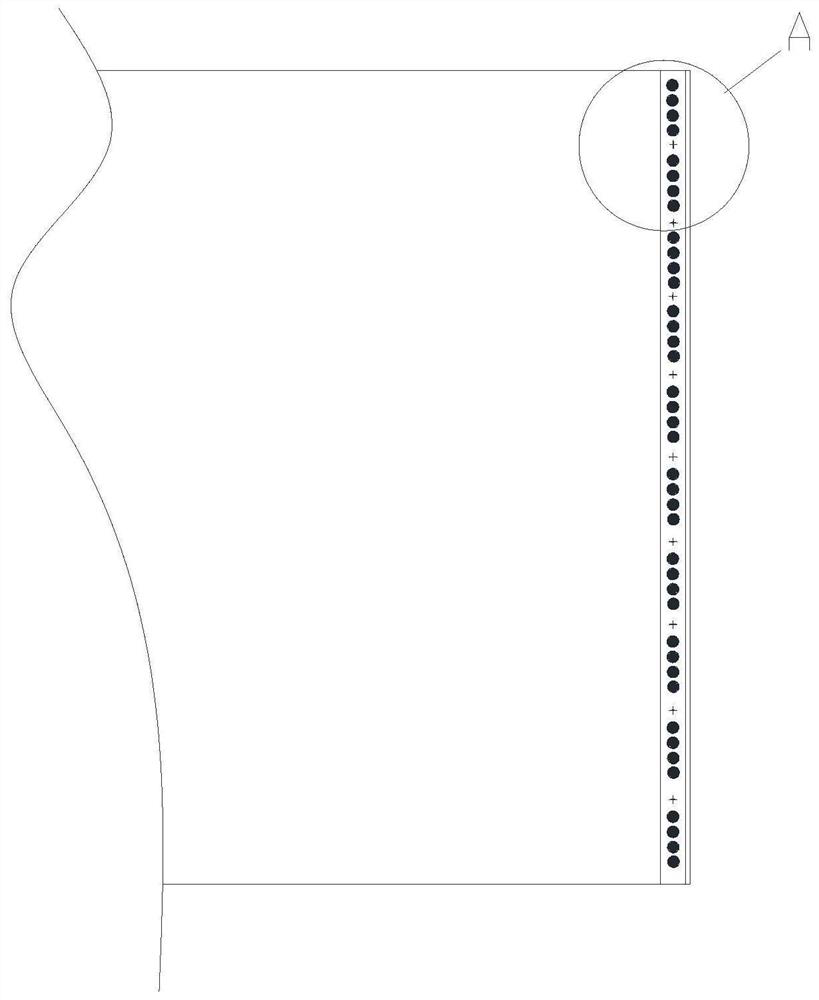

[0057] Step 2: Make flexible printing plates of various colors; the flexible printing plates of various colors include graphics and texts to be printed; dot reproduction monitoring icons are also included; and overprint monitoring icons are included;

[0058] Step 3: Install the flexographic printing plates of each color on the printing plate cylinder of the corresponding printing unit;

[0059] Step 4: detection of paper smoothness;

[0060] Step 5: Pre-printing;

[0061] (1) The printing speed is 20m / min; including n groups of printing unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com