High-quality online monitoring book and periodical production process capable of improving cementing quality

A production process and high-quality technology, applied in the printing field, can solve the problems of easy breakage, poor fatigue resistance and bending performance, and page falling off, and achieve the effect of not easy breakage, accurate judgment and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

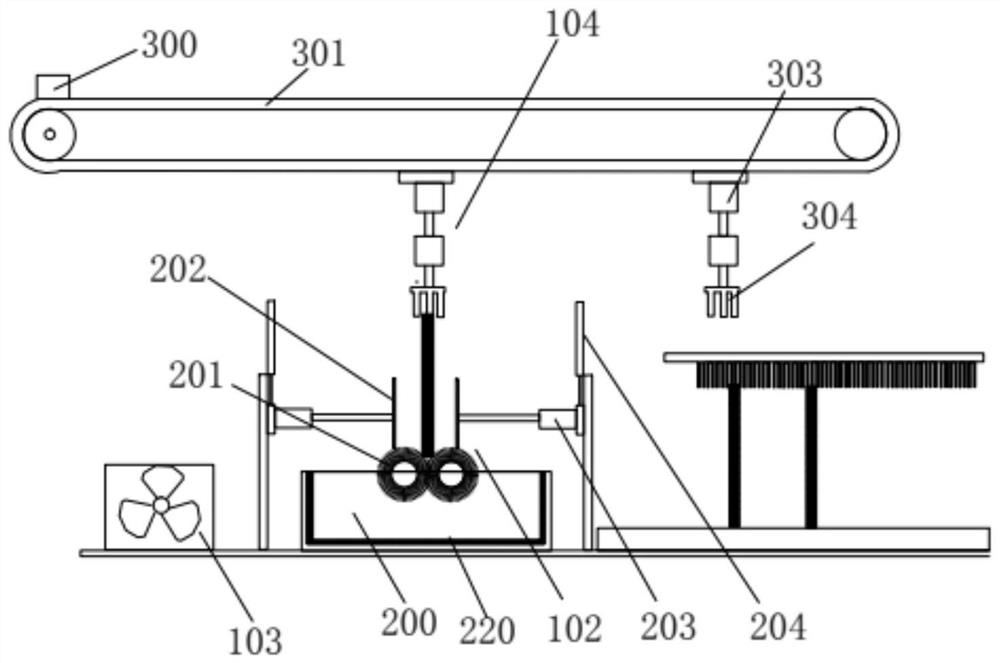

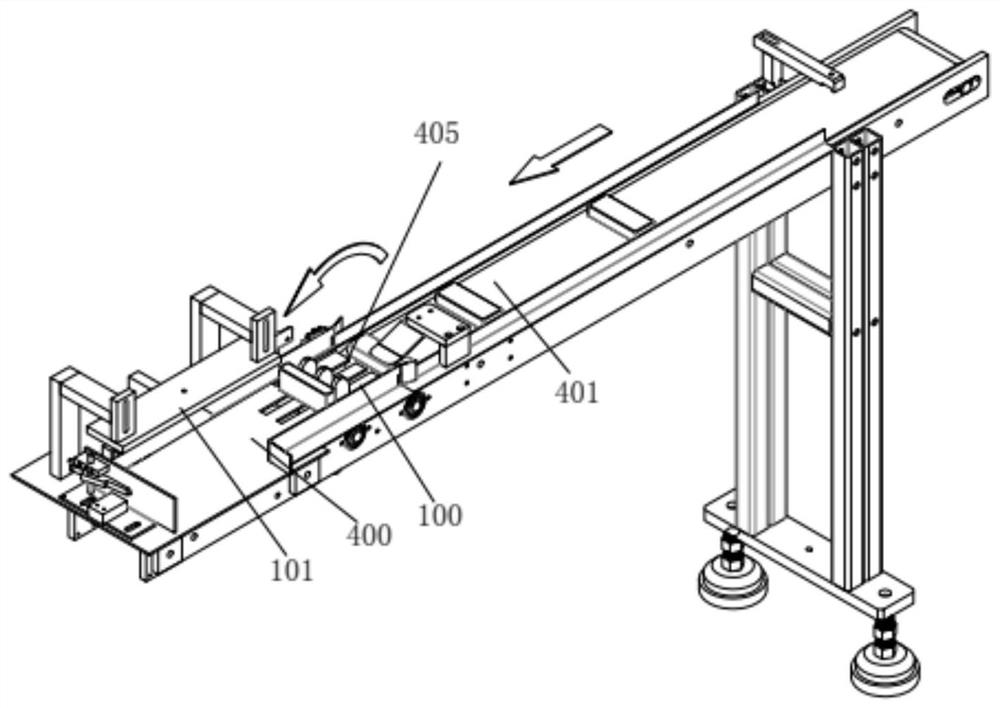

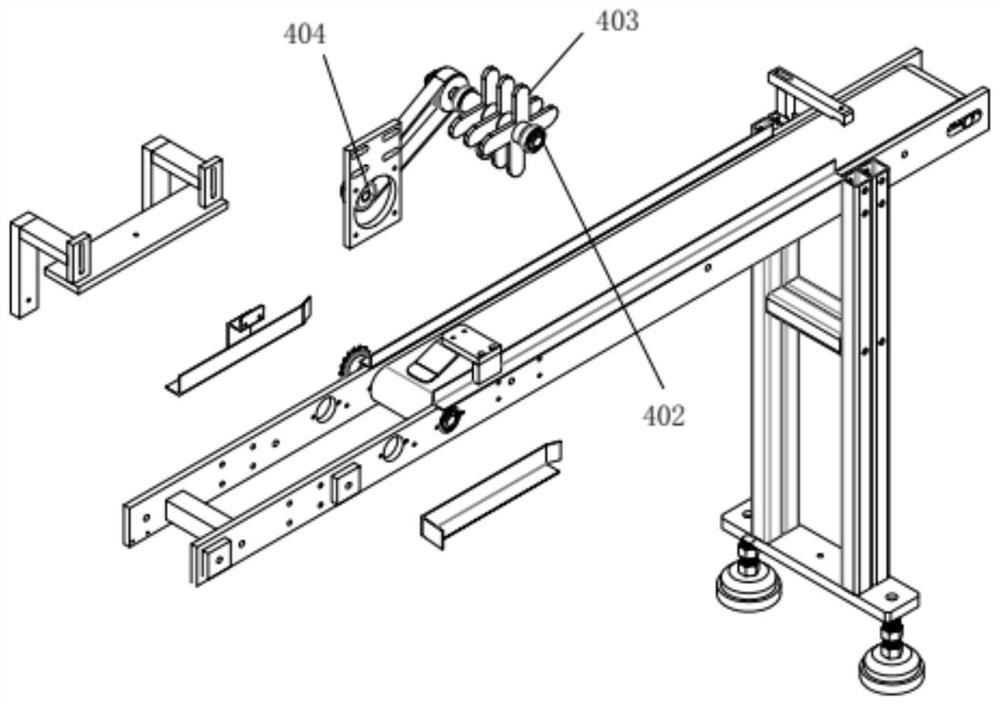

[0059] see Figure 1-7 , the present invention provides a technical solution:

[0060] A high-quality online monitoring book production process capable of improving the quality of glue binding, comprising the following steps:

[0061] Step 1: Design dot reproduction monitoring icons and overprint monitoring icons, and make plates for dot reproduction monitoring icons, overprint monitoring icons and graphics to be printed;

[0062] Step 2: Pre-printing; including the following sub-steps:

[0063] (3) It includes n groups of printing units, and along the paper conveying direction, a first image acquisition unit is arranged behind the nth group of printing units; the first image acquisition unit is used to photograph the surface of the printed paper, if the paper surface If there are printed graphics, stop the machine to obtain the dot reproduction monitoring icon and overprint monitoring icon image; (2) identify a complete set of dot reproduction monitoring icons; judge whethe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com