Low-temperature curing epoxy anticorrosive powder coating and preparation method thereof

A powder coating, low temperature technology, applied in the field of low temperature curing epoxy anti-corrosion powder coating and its preparation, can solve the problem of easy cracking of the coating, and achieve the effect of good low temperature curing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

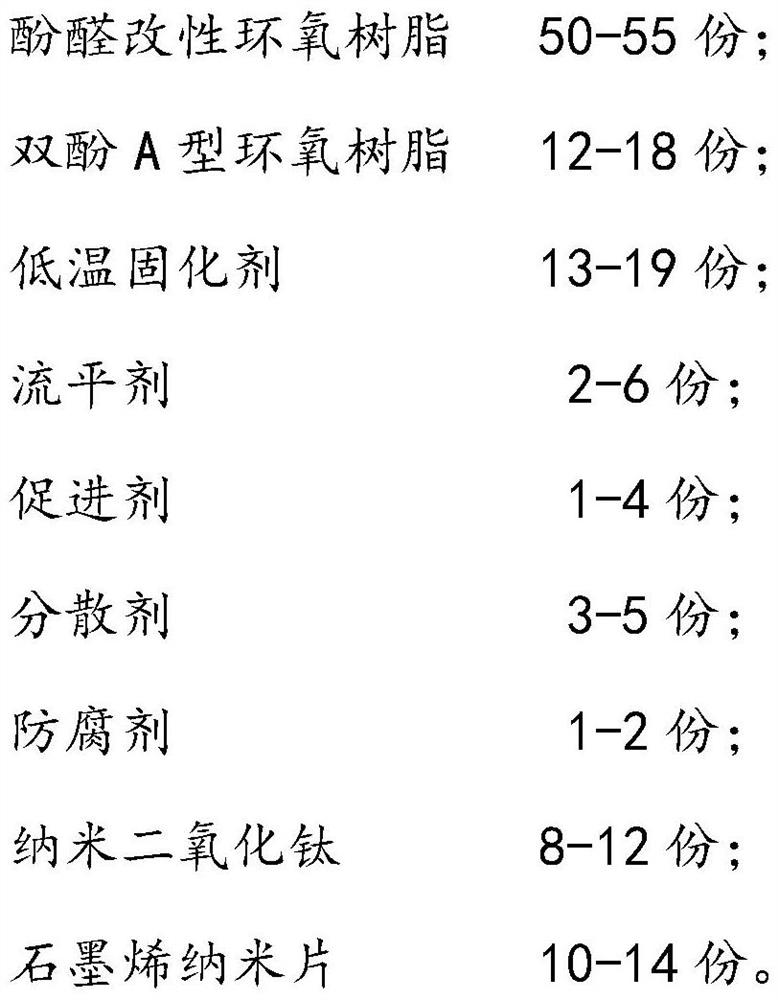

[0034] A kind of low-temperature curing epoxy anticorrosion powder coating of the present embodiment, it is made up of the component of following parts by weight:

[0035]

[0036] Wherein, the epoxy value of the phenolic modified epoxy resin is 0.11-0.13eq / 100g, and the softening point is 100-110°C. The dispersant is an ammonium salt dispersant. The low-temperature curing agent is toluene-2,4-bis[N,N-dimethylaminopropaneurea]. The accelerator is dimethylimidazole. The leveling agent is leveling agent H88.

[0037] The preparation method of the low-temperature curing epoxy anticorrosion powder coating of the present embodiment, comprises the steps:

[0038] S1. According to the formula content, pour each component into the container for thorough mixing, the stirring speed is 2500-3000r / min, and the stirring time is 45-60min;

[0039] S2. Pass the mixture obtained in S1 through an extruder, and perform melt extrusion at a temperature of 80-90° C.; wherein the screw speed...

Embodiment 2

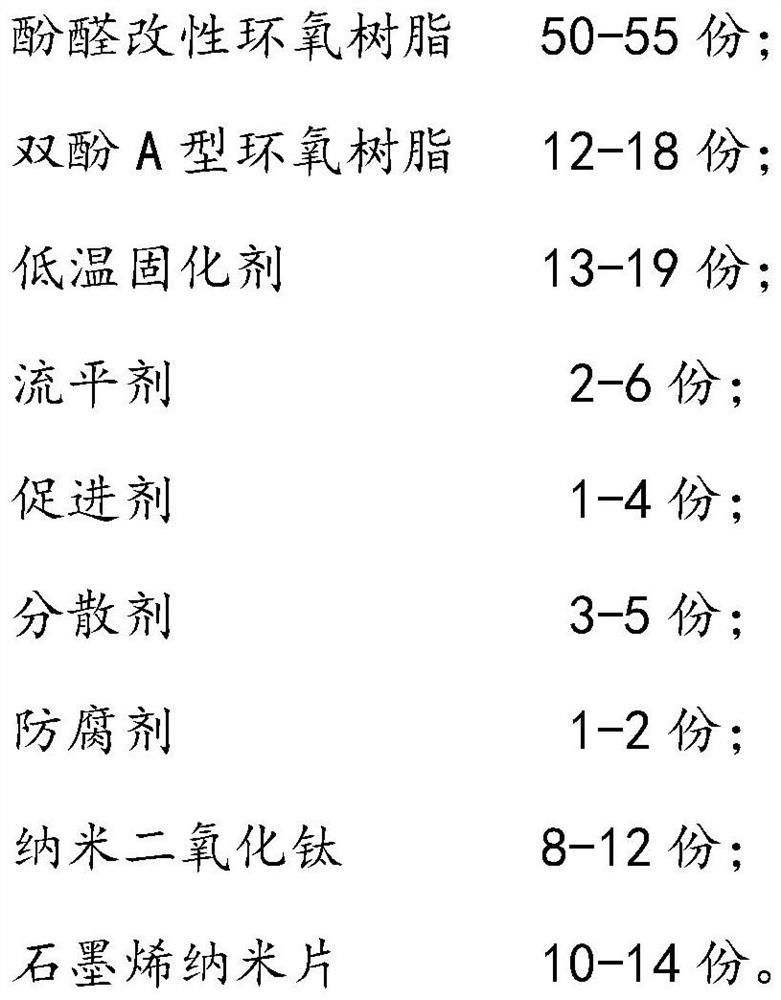

[0042] With reference to Example 1, different from Example 1, a kind of low-temperature curing epoxy anticorrosion powder coating of the present embodiment is made up of the following components by weight:

[0043]

[0044] The preparation method refers to Example 1.

Embodiment 3

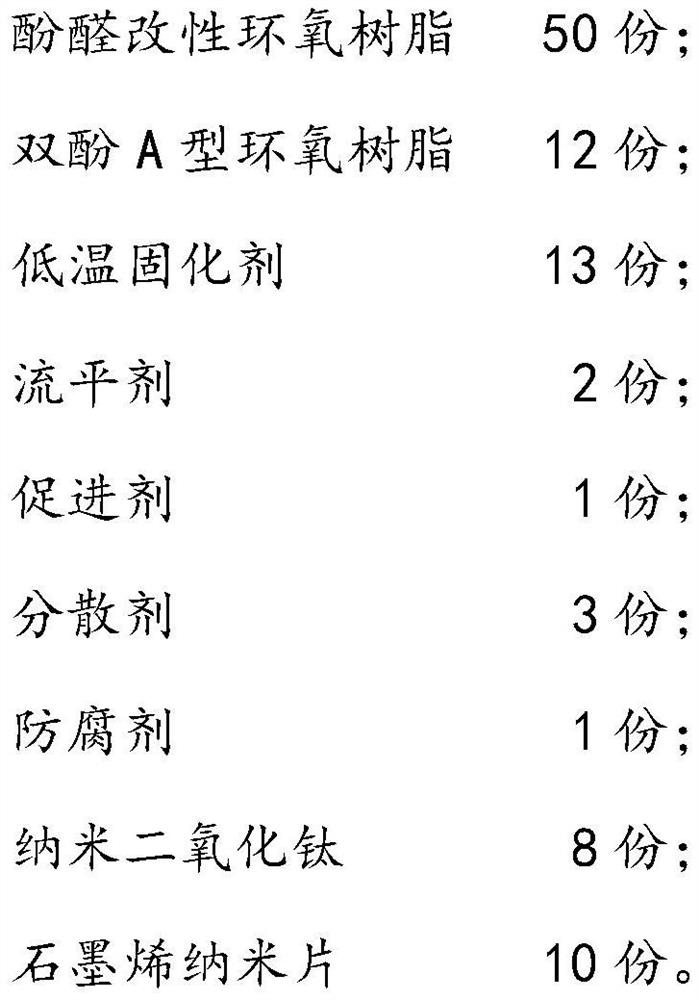

[0046] With reference to Example 1, different from Example 1, a kind of low-temperature curing epoxy anticorrosion powder coating of the present embodiment is made up of the following components by weight:

[0047]

[0048]

[0049] The preparation method refers to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com