Blow-off system for orbit control engine ground test

A technology for rail-controlled engines and ground tests, which is applied to engine testing, piping systems, and testing of machine/structural components, etc. Air entrained combustion and other problems, to achieve good blowing effect, isolation safety, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

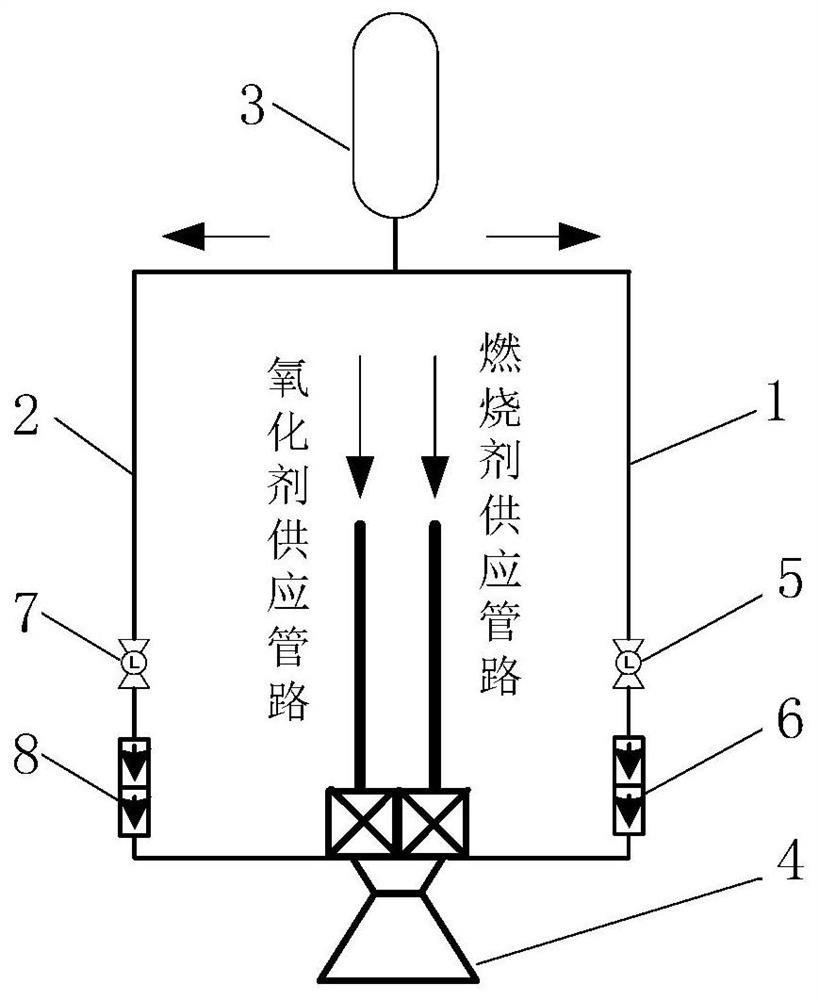

[0048] The invention provides a blow-off system for the ground test of an orbital control engine, such as figure 1 As shown, there are respectively a combustion agent blow-off pipeline 1 and an oxidant blow-off pipeline 2 between the blow-off gas source 3 and the orbit control engine 4, and the combustion agent blow-off pipeline 1 is used for the combustion agent in the orbit control engine 4. Blow-off, the oxidant blow-off pipeline 2 is used to blow off the oxidant in the rail control engine 4, along the direction of the output gas flow of the blow-off gas source 3, the combustion agent blow-off pipeline 1 is sequentially provided with a first control Valve 5, first one-way valve 6, second control valve 7, second one-way valve 8 are arranged on the oxidant blowing pipeline 2 in sequence.

[0049] The first control valve 5 and the second control valve 7 adopt pneumatic valves or electric valves, and the first one-way valve 6 and the second one-way valve 8 are preferably electr...

Embodiment 2

[0056] This embodiment is a preferred example of Embodiment 1.

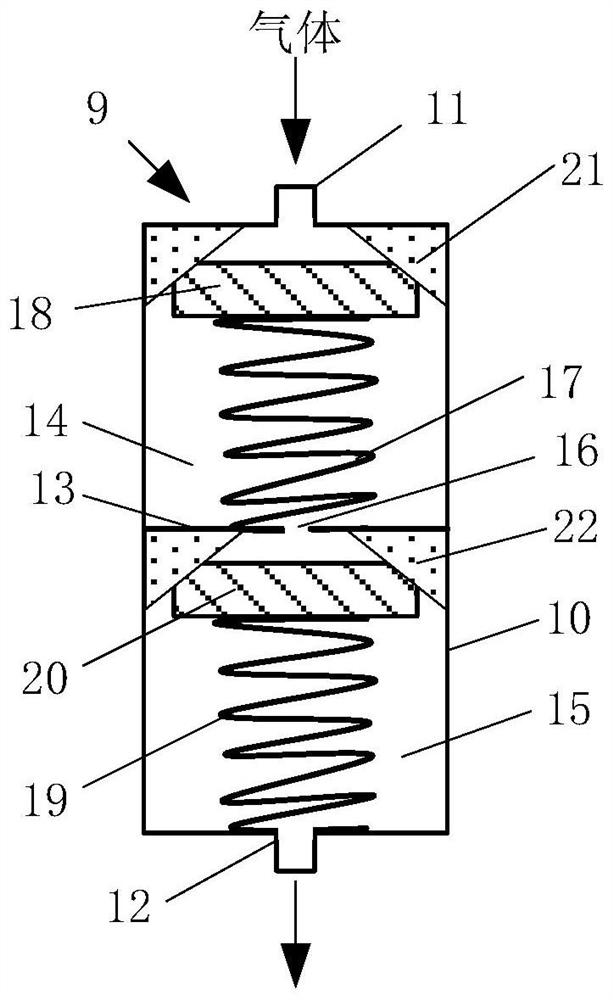

[0057] In this embodiment, the first one-way valve 6 and the second one-way valve 8 both use a double-seat one-way flow control valve 9, such as figure 2 As shown, the double-seat one-way flow control valve 9 includes a control valve housing 10 and an inlet port 11 and an outlet port 12 respectively arranged at both ends of the control valve housing 10. The inlet port 11 is connected to the first port through a pipeline. The control valve 5 or the second control valve 7 is connected, and the outlet port 12 is connected with the orbit control engine 4 through a pipeline.

[0058] The inside of the control valve housing 10 is provided with a partition 13 and the partition 13 divides the inside of the control valve housing 10 into a first chamber 14 and a second chamber 15 communicating with each other, the first chamber The interior of the chamber 14 is provided with a first core structure, and the interior of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com