Test system and method for turbine blade integrated thin film temperature sensor

A thin-film temperature and turbine blade technology, applied in the field of sensor testing, can solve the problems such as the inability of the integrated thin-film temperature sensor of the turbine blade to adopt the industrial thermocouple temperature measurement calibration method, the adverse effect on the life of the turbine blade and the thin-film temperature sensor, etc., so as to avoid the impact of life. , Reduce the impact of life, the effect of precise temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The contents of the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

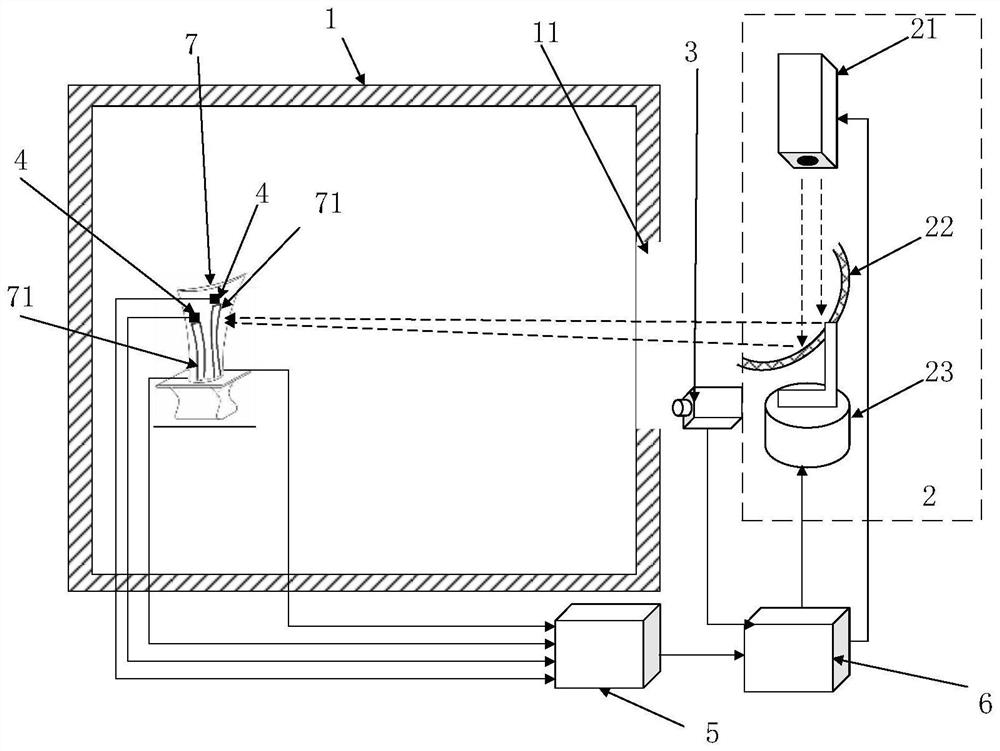

[0046] like figure 1 , The present invention provides a turbine blade test system integrated thin-film temperature sensor, comprising a heating chamber, the instantaneous heating unit 2, the imaging unit 3, a standard thermocouple 4, 5 prover and a control unit 6.

[0047]The heating box 1 is used to place the turbine blades 7 in order to facilitate the placement of the turbine blade 7, and the heating tank 1 is provided with a platform for placing the turbine blades 7 to be tested. In this example, the heating tank 1 is welded with a stainless steel plate, and the inner wall is filled with a ceramic insulation material; a ceramic heater is also provided in the heating box 1 for heating the heating tank 1 inner cavity, using a thermostat control pair heating tank 1 Internal overall heating; a temperature sensor is provided o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com