A mobile device for testing the glossiness of silicon wafer surface

A mobile device and a technology on the surface of a silicon wafer, which is applied in the direction of measuring devices, scattering characteristics measurement, and material analysis through optical means, can solve problems such as doubtful detection quality, difficulty in uniform quantification of samples, and low detection efficiency, and achieve accuracy assurance , Improve the effect of detection quality and detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

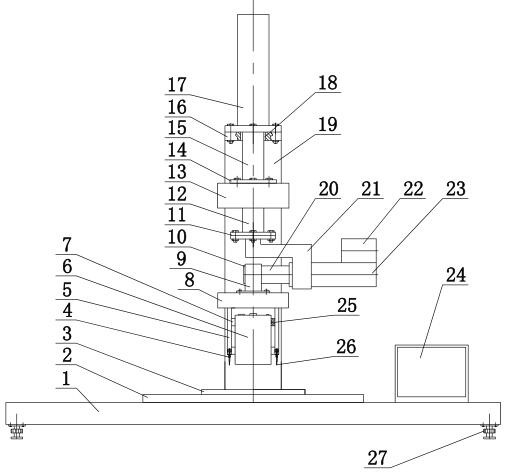

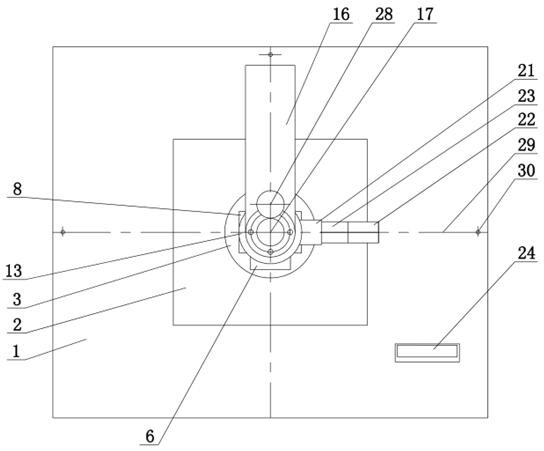

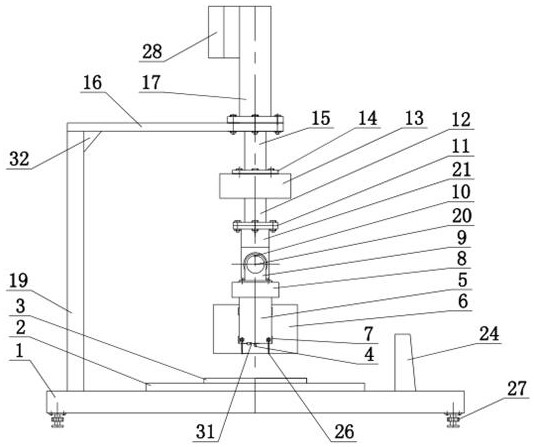

[0037] Such as Figure 1-Figure 4 As shown, a mobile device for testing the surface gloss of a silicon wafer includes a workbench 1 on which a horizontal centerline 29 is arranged, and a circular bubble level 30 is arranged on the horizontal centerline 29 . The four corners below the workbench 1 are respectively provided with height-adjusting pads 27, and the rotation of the height-adjusting pads 27 can make the bubbles in the circular bubble level 30 reach the central position so that the upper surface of the workbench 1 is level. The workbench 1 is provided with a work board 2, a test instrument carrier and a display PLC controller 24; the upper surface of the work board 2 is used to place the silicon wafer sample 3, and the test instrument carrier is used to carry the gloss meter 6, the gloss The detection port of the instrument 6 faces the upper surface of the working board 2, and the display PLC controller 24 is integrated with a display screen and a loudspeaker.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com