Method for judging coordinated control quality of coal-fired power plant

A technology of coordinated control and quality judgment, applied in the direction of electrical program control, program control, comprehensive factory control, etc., can solve problems such as high requirements for engineering practice personnel, lack of quantitative evaluation results, and inapplicability of some systems, and achieve data acquisition means Simple, scalable, and easy-to-understand effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

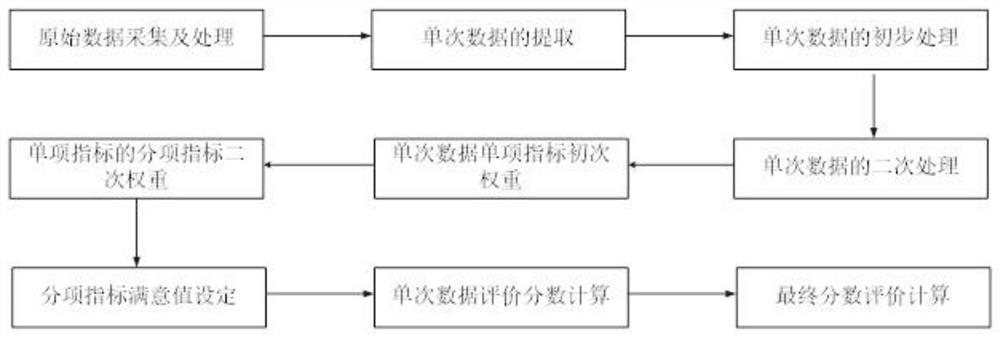

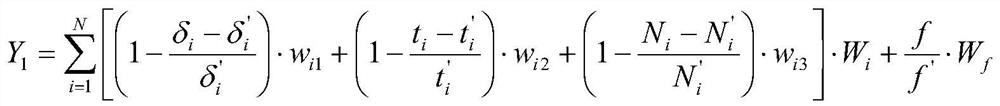

[0036]A coal-fired power station coordinated control quality judgment method, the specific steps are as follows:

[0037] Step S1: Establish OPC communication with the distributed control system of the power plant in order to extract data.

[0038] Step S2: When the rate of change of the load command exceeds the first threshold S within a certain period of time 1 When , start to extract the data used to characterize the coordinated control index; the extracted data includes the set value data U i and the feedback value data U Si , 1≤i≤N, N is the number of data types extracted; where, when i=1, U 1 is the actual load value, U S1 is the load command value.

[0039] Here U i and U Si It is a physical quantity with a specific physical meaning, and its characteristic is that it can represent the coordination control index. According to the DL / T657-2015 standard, the physical quantity that can represent the coordination control index has a defined meaning, such as the indicat...

specific Embodiment approach 2

[0052] Specific embodiment two: the difference between this embodiment and specific embodiment one is:

[0053] N=9

[0054] u 2 Main steam pressure feedback value, U S2 Main steam pressure setting value;

[0055] u 3 Main steam temperature feedback value, U S3 Main steam temperature set point;

[0056] u 4 is the reheat steam temperature feedback value, U S4 Set value for reheat steam temperature;

[0057] u 5 is the middle point temperature feedback value, U S5 Set value for the middle point temperature;

[0058] u 6 is the bed temperature feedback value, U S6 Set value for bed temperature;

[0059] u 7 is the drum water level feedback value, U S7 Set value for drum water level;

[0060] u 8 is the furnace pressure feedback value, U S8 Set value for furnace pressure;

[0061] u 9 is the feedback value of smoke content, U S9 Set value for smoke content.

[0062] This embodiment provides the data types that need to be obtained. These data types are highl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com