Intelligent control method for automatic load increasing and reducing of methanol rectification device

A technology of intelligent control and methanol rectification, applied in the direction of distillation adjustment/control, chemical instruments and methods, fractionation, etc., can solve problems such as system fluctuations and energy waste, and achieve the effect of overcoming system fluctuations and energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0019] The first embodiment of the present invention is an intelligent control method for automatic loading and unloading of a methanol rectification device, comprising the following steps:

[0020] The real-time temperature of each temperature point in the pre-distillation tower, pressurization tower, atmospheric tower and recovery tower is obtained through the DCS system of the intelligent control system;

[0021] The above real-time temperature is corrected by the pressure correction temperature soft sensor to obtain the corrected temperature;

[0022] Set the above-mentioned correction temperature and the first parameter of the pre-distillation tower, the pressurization tower, the atmospheric tower and the recovery tower on the operation interface; and

[0023] The intelligent control system sets the second parameters of the pre-distillation tower, pressurization tower, atmospheric tower and recovery tower according to the set correction temperature, and realizes the contr...

Embodiment 1

[0033] An intelligent control method for automatic loading and unloading of a methanol rectification device, the specific steps are as follows:

[0034] Step 1: The intelligent control system reads the temperature of each temperature point in the pre-distillation tower, pressurization tower, atmospheric tower and recovery tower through the DCS system, and the pressure is corrected by the pressure correction temperature soft sensor of the intelligent control system The temperature is displayed on the intelligent control system operation interface.

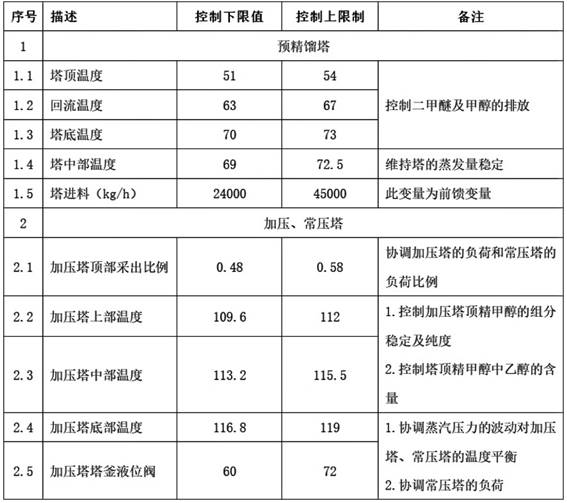

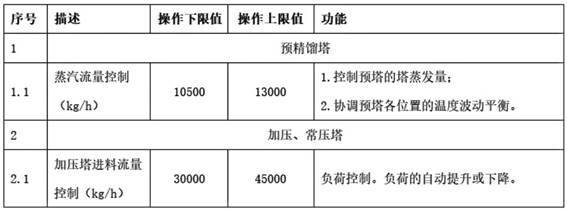

[0035] Step 2: Set the crude methanol feed to the pre-distillation tower (gradient change), and at the same time set the temperature of the pre-distillation tower, pressurization tower, atmospheric tower and recovery tower on the operation interface of the intelligent control system (the temperature is the temperature calculated by the soft instrument after pressure correction), as shown in Table 1.

[0036] Table 1

[0037]

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com