Anti-seismic bridge plate type rubber support

A rubber bearing and bridge plate technology, applied in bridges, bridge parts, bridge construction, etc., can solve the problem of time-consuming and laborious bottom installation, and cannot cope with earthquakes, so as to avoid rapid breakage and prolong the time of earthquake resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention. The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

[0038] The embodiments of the present invention will be described below according to the overall structure of the present invention.

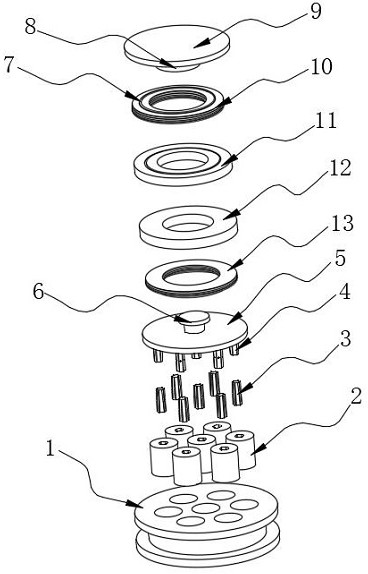

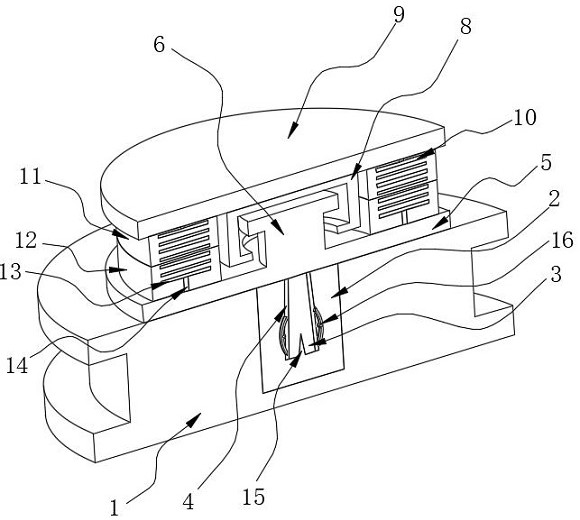

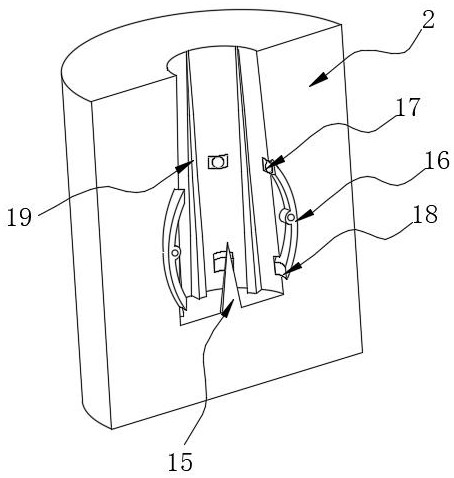

[0039] An anti-seismic bridge plate rubber bearing, such as figure 1As shown, including the bottom embedded part 1, the bottom embedded part 1 is set as the base for fixing the bottom, and the upper end of the bottom embedded part 1 is provided with multiple sets of fixing cylinders 2, and the connecting petal 4 is fixed through the fixing cylinder 2. When After the connecting flap 4 is stretched by the self-locking column 3 in the fixed cylinder 2, a self-locking str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com