Intelligent prefabricated pump station

A pumping station, intelligent technology, applied in water/sludge/sewage treatment, drainage structures, buildings, etc., can solve the problems of low cleaning efficiency, poor cleaning effect, and high cleaning cost, so as to reduce cleaning costs and improve The effect of retention capacity and improvement of filtration capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

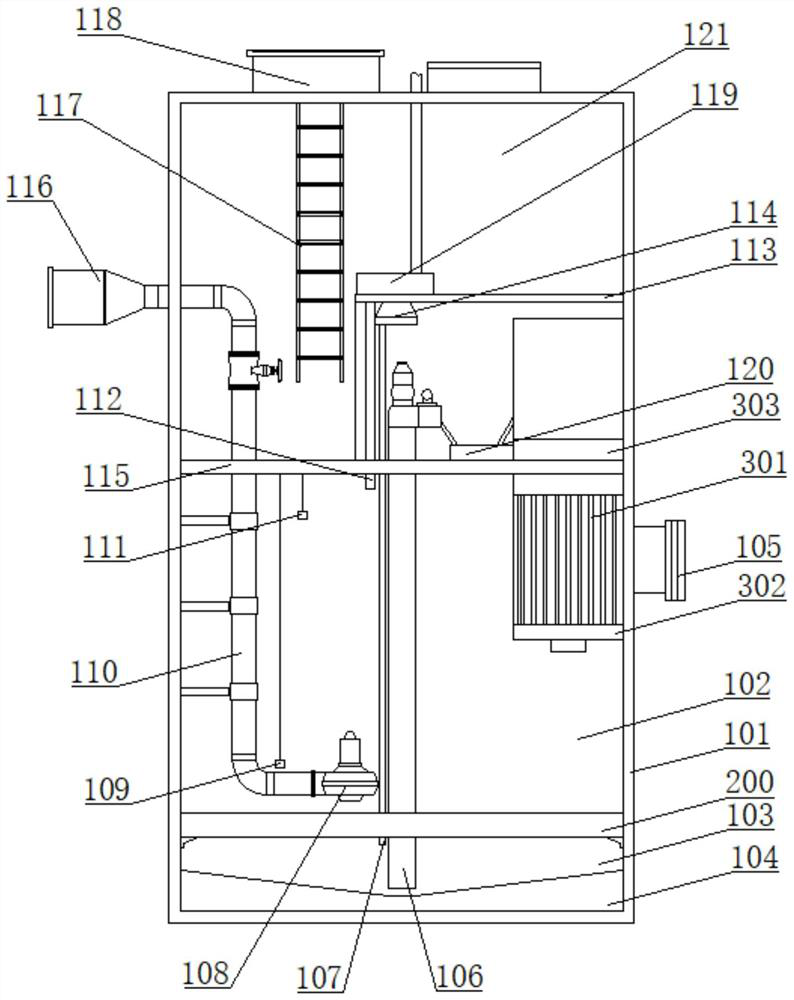

[0036] As shown in the figure, an intelligent prefabricated pumping station includes a casing 101 , and a partition 115 is arranged inside the casing 101 . The partition 115 divides the inner chamber of the casing 101 into an operation chamber 121 and a water storage chamber 102 . A water inlet 105 is provided on the housing 101 at one side of the water storage chamber 102 . A water pump 108 is provided in the water storage chamber 102 , and the water pump 108 is connected to a water outlet 116 provided on the housing 101 on one side of the operation chamber 121 through a water pipe 110 . The water entering from the water inlet 105 will be stored in the water storage chamber 102 , then pumped by the water pump 108 and flow out from the water outlet 116 .

[0037] In the water storage chamber 102, there are ultra-high liquid level mechanical weight float 111 and ultra-low liquid level mechanical weight float 109, so that the liquid level in the water storage chamber 102 can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com