Preparation method of nicandra physaloides gum/polyvinyl alcohol composite hydrogel with porous structure

A composite hydrogel, porous structure technology, applied in water/sewage treatment, general water supply conservation, chemical instruments and methods, etc. Weak capacity and other problems, to achieve the effect of enhancing the interception capacity and reducing the evaporation enthalpy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] After adding 1g of polyvinyl alcohol to dissolve at 60°C, stir until the solution is uniform and stable. Add 125 μL of glutaraldehyde and 100 μL of polypyrrole solution, ultrasonically mix evenly, then stir and add 500 μL of hydrochloric acid solution and 100 μL of calcium chloride solution. The mixed solution was injection molded and sealed, and after gelling at room temperature for 2 hours, it was soaked in deionized water for 24 hours to obtain a hydrogel. The hydrogel was frozen with liquid nitrogen, thawed in a water bath at 30° C., and the polyvinyl alcohol hydrogel was obtained by repeated freezing and thawing 10 times.

Embodiment 2

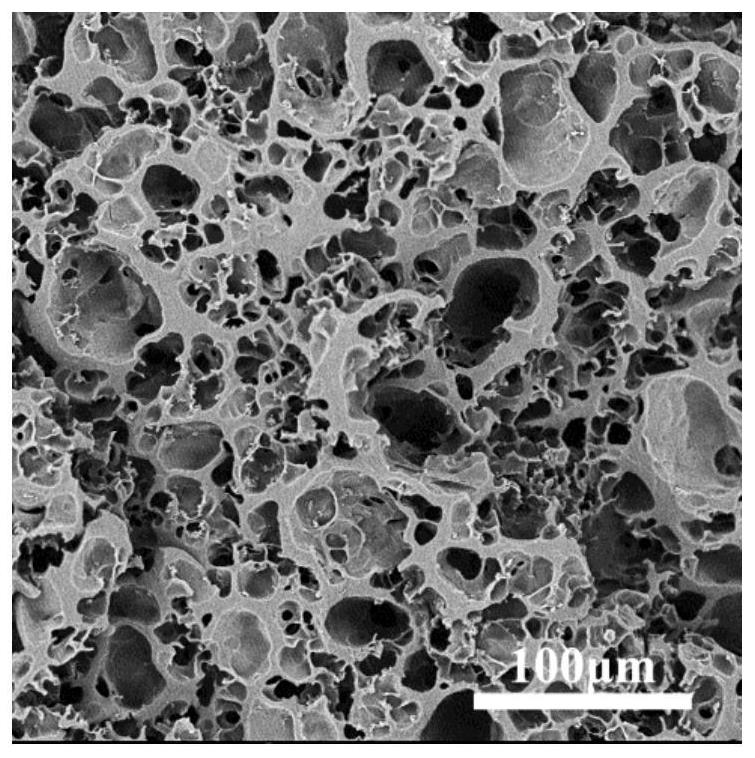

[0027] First, 0.005g of pseudophysalis powder was dissolved in 10mL of deionized water at 40°C. Then add 0.995g of polyvinyl alcohol to dissolve at 70°C, and stir until the solution is uniform and stable. Add 125 μL of glutaraldehyde and 100 μL of polypyrrole solution, ultrasonically mix evenly, then stir and add 500 μL of hydrochloric acid solution and 100 μL of calcium chloride solution. The mixed solution was injection molded and sealed, and after gelling at room temperature for 2 hours, it was soaked in deionized water for 24 hours to obtain a composite hydrogel. The composite hydrogel was frozen in liquid nitrogen, thawed in a water bath at 30°C, and the double network hydrogel was obtained by repeated freezing and thawing 10 times.

Embodiment 3

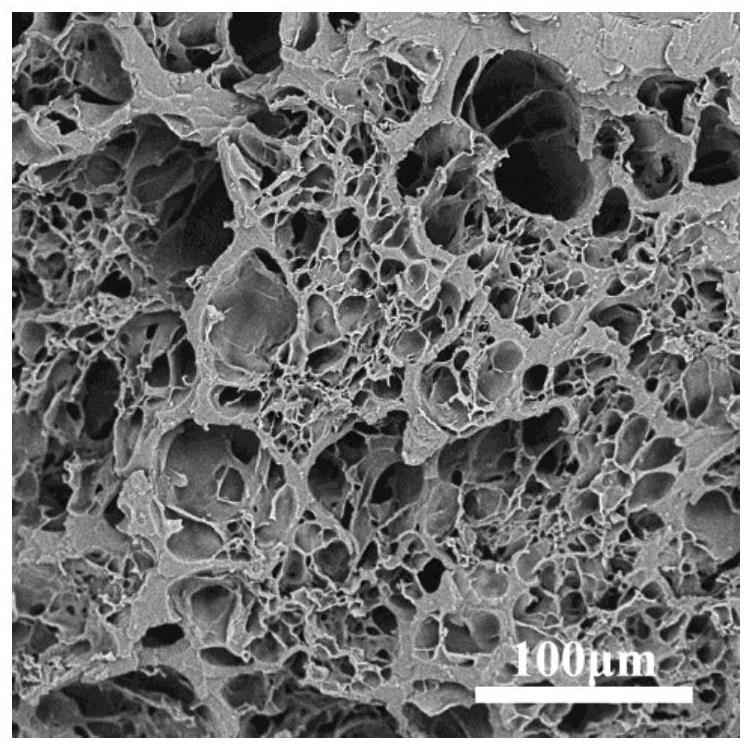

[0029] First, 0.025g of pseudophysalis powder was dissolved in 10mL of deionized water at 50°C. Then add 0.975g of polyvinyl alcohol to dissolve at 50°C, and stir until the solution is uniform and stable. Add 125 μL of glutaraldehyde and 100 μL of polypyrrole solution, ultrasonically mix evenly, then stir and add 500 μL of hydrochloric acid solution and 100 μL of calcium chloride solution. The mixed solution was injection molded and sealed. After gelling at room temperature for 2 hours, it was soaked in deionized water for 24 hours to obtain a composite hydrogel. The composite hydrogel was frozen in liquid nitrogen, thawed in a water bath at 30°C, and the freeze-thaw was repeated 10 times to obtain a uniform porous double network hydrogel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com