Preparation of corn starch/sodium alginate/MXene composite hydrogel and application of corn starch/sodium alginate/MXene composite hydrogel in seawater desalination

A composite hydrogel and corn starch technology, which is applied in gel preparation, water/sludge/sewage treatment, colloid chemistry, etc., can solve problems such as easy deposition of salt, restrictions on wide application, cumbersome preparation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

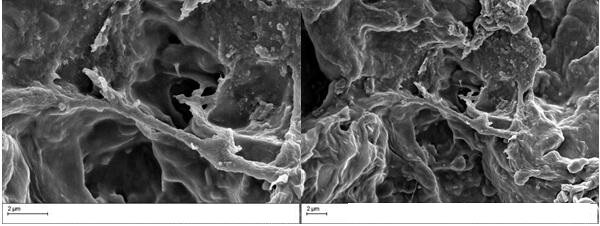

[0035] (1) The preparation method of MXene: Dissolve 1gLiF into 20mL 9mol / L HCl solution with magnetic stirring for 5min, then dissolve 1gTi 3 AlC 2The powder was slowly added to the above solution, and the mixed solution was magnetically stirred at 40°C for 48 hours to obtain a stable suspension, centrifuged at 3500rpm for 5 minutes, washed repeatedly with deionized water until PH = 6~7, and the sediment was dissolved in 200mL Deionized water, sonicated for 2 h under ice bath conditions, and then the solution was pre-frozen in the refrigerator for 12 h, and then freeze-dried to obtain MXene powder, which was refrigerated for later use.

[0036] (2) Preparation of cornstarch / sodium alginate / MXene composite hydrogel: weigh 0.1g of sodium alginate, 0.1g of cornstarch, and 12.5mg of MXene in 10mL of deionized water to obtain a mixed solution, and stir at 80°C for 1h , to gelatinize the cornstarch, and finally add 2mL of 0.45mol / L calcium chloride solution under the condition of ...

Embodiment 2

[0039] (1) Preparation method of MXene: same as Example 1;

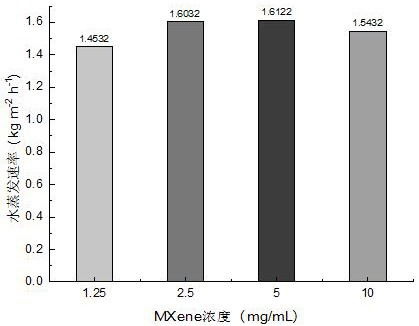

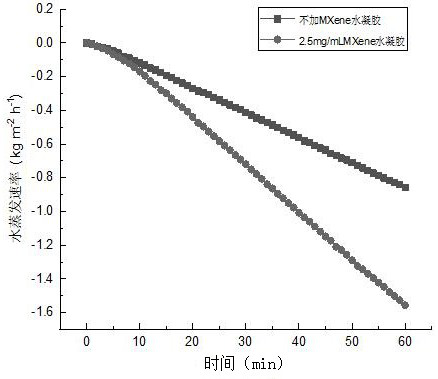

[0040] (2) Preparation of cornstarch / sodium alginate / MXene composite hydrogel: weigh 0.1g of sodium alginate, 0.1g of cornstarch, and 25mg of MXene in 10mL of deionized water to obtain a mixed solution, and stir at 80°C for 1h , to gelatinize the cornstarch, and finally add 2mL of 0.45mol / L calcium chloride solution under the condition of rapid stirring, and cross-link at 25°C for 5min to form a cornstarch / sodium alginate / MXene composite hydrogel. The water evaporation rate of the composite hydrogel is 1.60kg m -2 h -1 , the ion concentration before and after seawater desalination is as follows:

[0041]

Embodiment 3

[0043] (1) Preparation method of MXene: same as Example 1;

[0044] (2) Preparation of cornstarch / sodium alginate / MXene composite hydrogel: weigh 0.1g of sodium alginate, 0.1g of cornstarch, and 50mg of MXene in 10mL of deionized water to obtain a mixed solution, and stir at 80°C for 1h , to gelatinize the cornstarch, and finally add 2mL of 0.45mol / L calcium chloride solution under the condition of rapid stirring, and cross-link at 25°C for 5min to form a cornstarch / sodium alginate / MXene composite hydrogel. The water evaporation rate of the composite hydrogel is 1.61kg m -2 h -1 , the ion concentration before and after seawater desalination is as follows:

[0045]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com