High-molecular hydrogel film with piezoelectric property as well as preparation and application of high-molecular hydrogel film

A polymer hydrogel, piezoelectric performance technology, applied in seawater treatment, water/sewage treatment, general water supply conservation, etc. Piezoelectric output capability, increased water activation capability, effect of high output voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

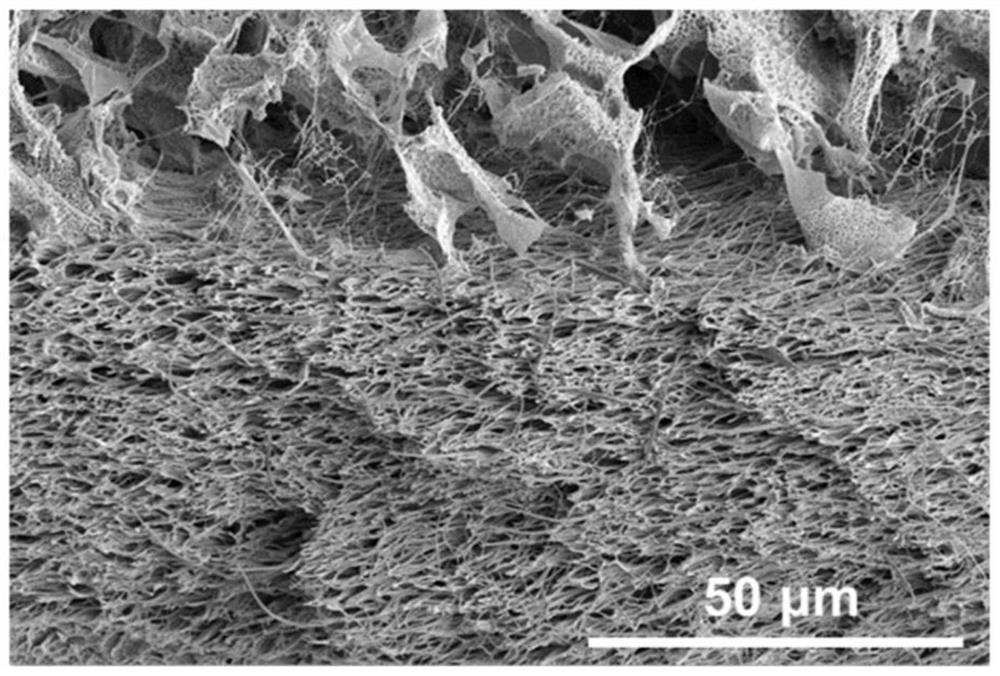

[0047] A kind of polyvinyl alcohol hydrogel composite film, its preparation method is as follows:

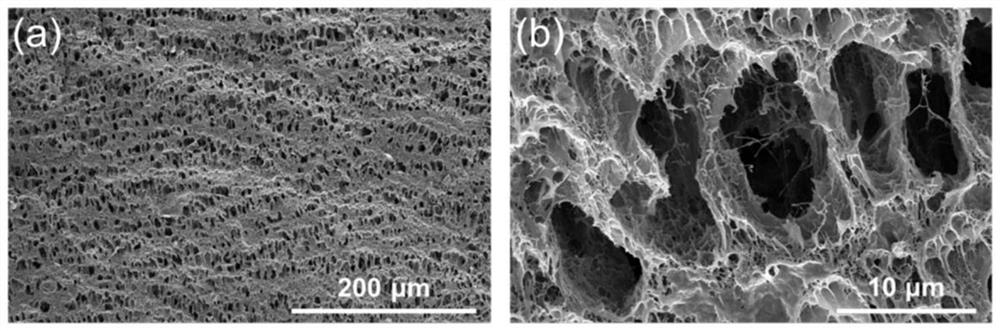

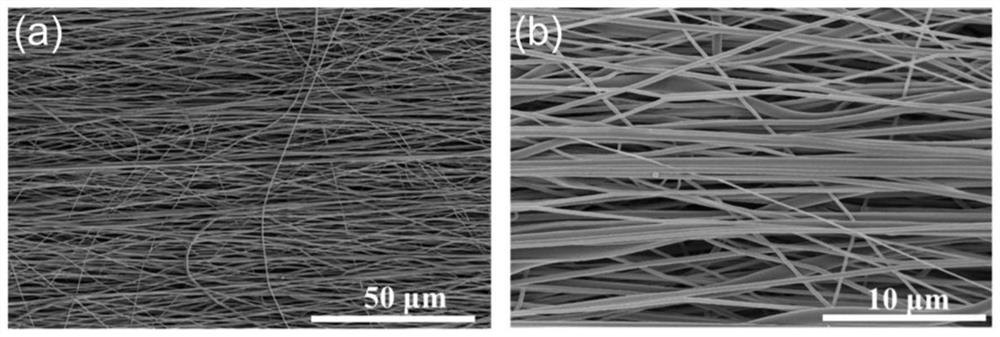

[0048] First prepare a porous polymer piezoelectric film: take 0.75g of polyvinylidene fluoride-trifluoroethylene copolymer and add it to 5ml of a mixed solution of N,N-dimethylformamide and acetone (N,N-difluoroethylene in the mixed solution The volume ratio of methylformamide and acetone is 3:2), stirring at room temperature to make it fully dissolved; the mixed solution is prepared into a film by electrospinning technology, and the rotation speed of the collecting roller is adjusted to 3000rpm to obtain a highly oriented structure. Fiber membrane; put the aforementioned fiber membrane in an oven at 60° C. for 24 hours to remove residual solvent; obtain the final piezoelectric membrane with a highly oriented structure. Get 100mg of graphene oxide powder and add it to a mixed solution of 50ml of deionized water and glycerol (the mass ratio of water and glycerol in the mixed sol...

Embodiment 2

[0054] A kind of polyvinyl alcohol hydrogel composite film, its preparation method is as follows:

[0055] First prepare a porous polymer piezoelectric film: take 0.75g of polyvinylidene fluoride and add it to 5ml of a mixed solution of N,N-dimethylformamide and acetone (N,N-dimethylformamide and acetone in the mixed solution The volume ratio is 3:2), stirring at room temperature to make it fully dissolved; the mixed solution is prepared into a film by electrospinning technology, and the rotating speed of the collecting roller is adjusted to 3000rpm to obtain a fiber film with a highly oriented structure; The film was placed in an oven at 60°C for 24 hours to remove residual solvent; the final piezoelectric film with a highly oriented structure was obtained.

[0056] Get 100mg of graphene oxide powder and add it to a mixed solution of 50ml of deionized water and glycerol (the mass ratio of water and glycerol in the mixed solution is 9:1), and ultrasonically treat it for 30min to...

Embodiment 3

[0059] A kind of polyvinyl alcohol hydrogel composite film, its preparation method is as follows:

[0060] First prepare a porous polymer piezoelectric film: take 0.75g of polyvinylidene fluoride-trifluoroethylene copolymer and add it to 5ml of a mixed solution of N,N-dimethylformamide and acetone (N,N-difluoroethylene in the mixed solution The volume ratio of methylformamide and acetone is 3:2), stirring at room temperature to make it fully dissolved; the mixed solution is prepared into a film by electrospinning technology, and the rotation speed of the collecting roller is adjusted to 3000rpm to obtain a highly oriented structure. Fiber membrane; put the aforementioned fiber membrane in an oven at 60° C. for 24 hours to remove residual solvent; obtain the final piezoelectric membrane with a highly oriented structure.

[0061] Take 25mg of graphene oxide powder and add it to a mixed solution of 50ml of deionized water and glycerol (the mass ratio of water and glycerol in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com