High-pressure extrusion dehydrator and using method thereof

A squeeze dehydrator, high-pressure technology, applied in dryers, dry solid materials without heating, dry goods processing, etc., can solve the problem of inability to realize multi-directional drainage during the extrusion process, reduce garbage processing time, and complex internal structure, etc. problems, to achieve the effect of improving drainage efficiency, convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

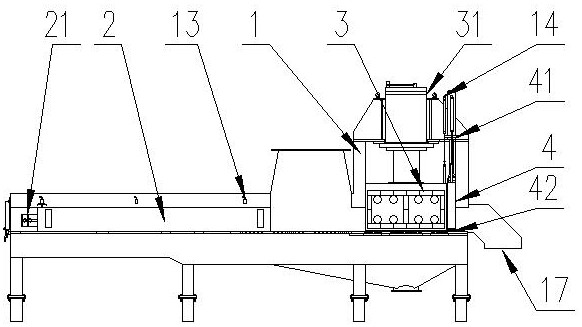

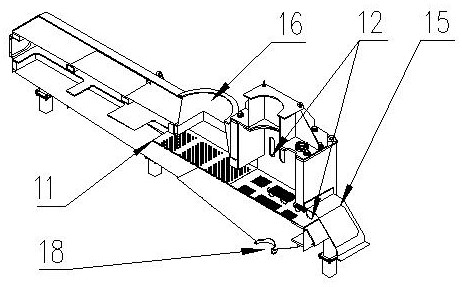

[0052] As a preferred embodiment of the present invention, this embodiment provides a high-pressure extrusion dehydrator, including an extrusion equipment frame 1, a feeding pusher 2 and an extrusion pusher 3, and the two sides of the extrusion equipment frame 1 Set as a feeding part and an extruding part, the feeding push head 2 is arranged in the feeding part, the extruding push head 3 is arranged in the extruding part, and the feeding push head 2 and the extruding push head 3 are both provided with The driving mechanism is provided with a feed inlet 16 above the feeding part, a discharge port 17 is provided on one side of the extrusion part, a water outlet 18 is provided below the extrusion equipment frame 1, and a sealing gate 4 is provided at the extrusion part. The gate is provided with a driving mechanism, the two sides of the extrusion push head 3 are designed with side drainage holes, the bottom surface of the extrusion push head 3 is provided with bottom surface drain...

Embodiment 2

[0055] As another preferred embodiment of the present invention, refer to the attached figure 1 , the present embodiment provides a high-pressure extrusion dehydrator, including an extrusion equipment frame 1, a feeding pusher 2 and an extrusion pusher 3, and the two sides of the extrusion equipment frame 1 are set as a feeding part and an extrusion part, the feeding push head 2 is set in the feeding part, the extrusion push head 3 is set in the extrusion part, the feeding push head 2 and the extrusion push head 3 are both provided with a driving mechanism, and There is a feed port 16, a discharge port 17 is provided on one side of the extruding part, and a water outlet 18 is provided under the extruding equipment frame 1. The extruding part is provided with a sealing gate 4, and a driving mechanism is provided on the gate. Both sides of the extrusion pushing head 3 are designed with side drainage holes, the bottom surface of the extrusion pushing head 3 is provided with botto...

Embodiment 3

[0058] As another preferred embodiment of the present invention, this embodiment provides a high-pressure extrusion dehydrator, including an extrusion equipment frame 1, a feeding pusher 2 and an extrusion pusher 3, the extrusion equipment frame 1 The two sides are set as a feeding part and an extruding part. The feeding pusher 2 is arranged at the feeding part, and the extruding pusher 3 is arranged at the extruding part. The feeding pusher 2 and the extruding pusher 3 are both A drive mechanism is provided, a material inlet 16 is provided above the feeding part, a discharge port 17 is provided on one side of the extruding part, a water outlet 18 is provided under the extruding equipment frame 1, and a sealing gate 4 is provided on the extruding part , the gate is provided with a drive mechanism, the two sides of the extrusion push head 3 are designed with side drainage holes, the bottom surface of the extrusion push head 3 is provided with bottom surface drainage holes, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com