Commercial livestock fattening agricultural feed production granulation device

A livestock and granulation technology, applied in feed, mold extrusion granulation, food science and other directions, can solve the problems of complex granulation steps, low efficiency, time-consuming and other problems, and achieve the effect of saving manpower and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

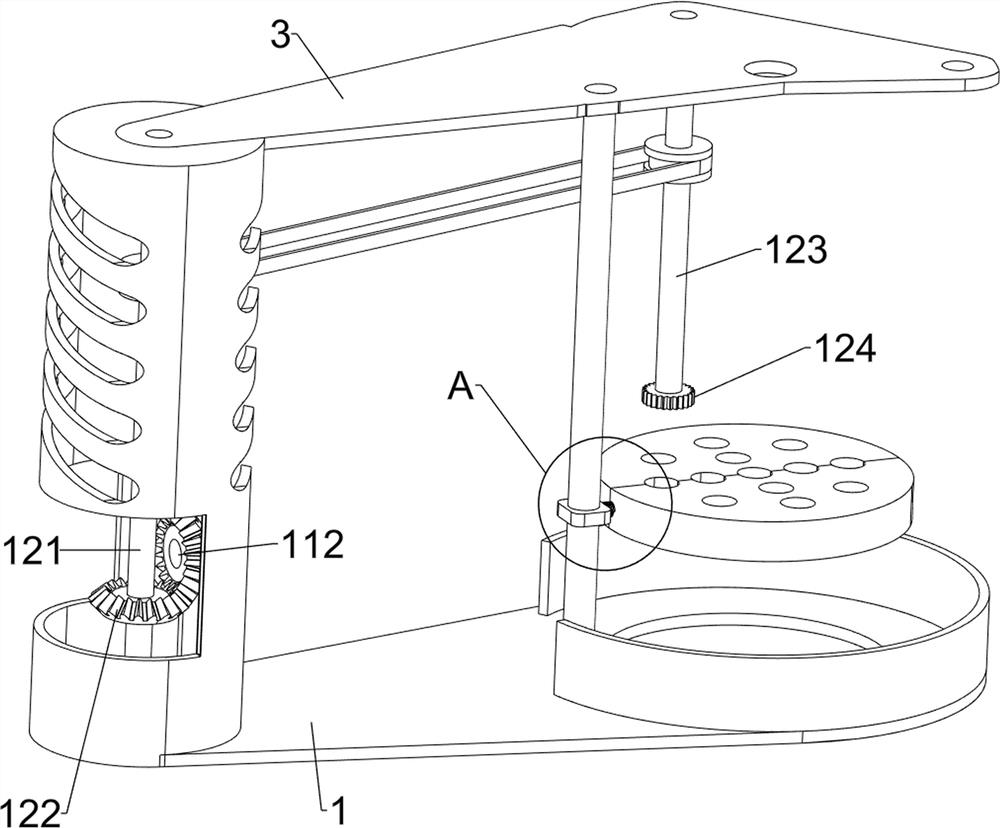

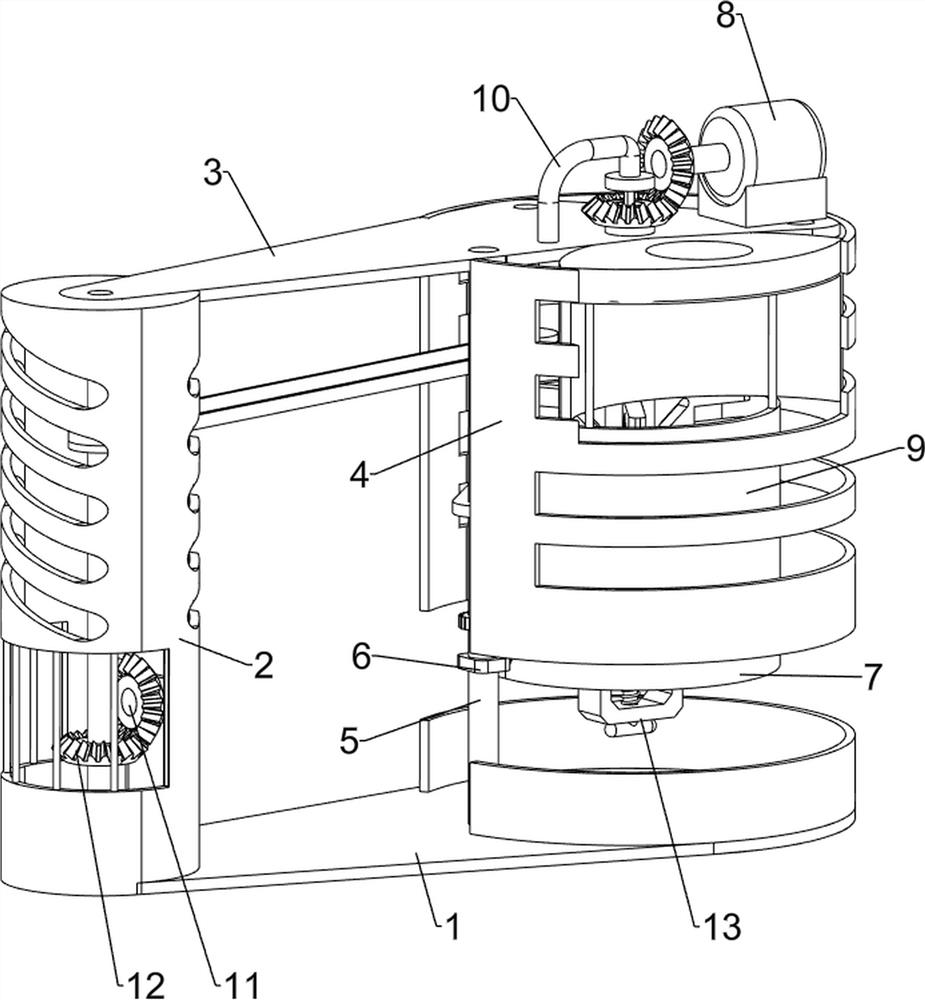

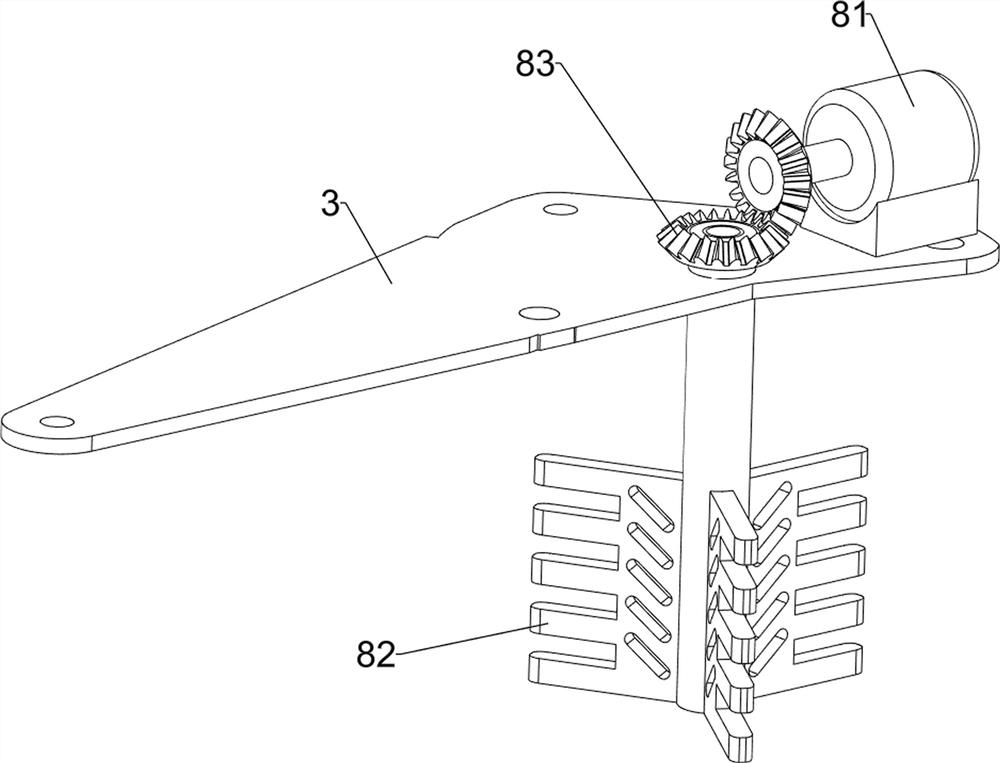

[0031] A commercial livestock fattening agricultural feed production granulation device, such as Figure 1-3 As shown, it includes a bottom plate 1, a support frame 2, a top plate 3, a side frame 4, a first rotating shaft 5, a rotating plate 6, a granulation mold 7, a driving assembly 8 and a loading assembly 9, and the upper left side of the bottom plate 1 is connected with a support Frame 2, the upper right side of the support frame 2 is connected with a top plate 3, the lower right side of the top plate 3 is connected with a side frame 4, the first rotating shaft 5 is connected in a rotational manner between the top plate 3 and the right side of the bottom plate 1, and the lower part of the first rotating shaft 5 is connected with Turning plate 6, the right side of turning plate 6 is rotatably connected with granulation mold 7, the upper right side of top plate 3 is connected with driving assembly 8, and the upper front side of side frame 4 is connected with loading assembly...

Embodiment 2

[0036] On the basis of Example 1, such as figure 1 and Figure 4 As shown, a rotating assembly 10 is also included, and the rotating assembly 10 includes a connecting rod 101, a first rhombic rod 102, a slide rod 103, a second rhomboid rod 104 and a first spring 105, and the upper right side of the top plate 3 is connected with a connecting rod 101 , the lower part of the right side of the connecting rod 101 is connected with a first rhombus rod 102, the upper part of the first rhombus rod 102 is slidably connected with a slide bar 103, and the lower part of the stirring rod 82 is slidably connected with a second rhombic rod 104, and the second rhombus rod 104 is connected with the lower The material plate 92 cooperates, and the first spring 105 is connected between the second diamond-shaped rod 104 and the stirring rod 82 .

[0037] When the stirring rod 82 rotates, the stirring rod 82 rotates to drive the slide bar 103 to move downward, the slide bar 103 moves downward to d...

Embodiment 3

[0039] On the basis of Example 2, such as figure 1 , Figure 5 and Figure 6As shown, it also includes an overturn assembly 11, which includes a connecting plate 111, a sleeve rod 112, a first one-way gear 113, an arc-shaped rack 114, a rhombic wedge-shaped rod 115 and a second spring 116, and the lower part of the support frame 2 The right side is connected with a connecting plate 111, the middle part of the connecting plate 111 is rotatably connected with a sleeve rod 112 on the right side, the bottom of the first rotating shaft 5 is connected with a first one-way gear 113, and the middle of the left side of the wiper plate 93 is connected with an arc-shaped rack 114. The arc-shaped rack 114 meshes with the first one-way gear 113, and the middle of the right part of the granulation mold 7 is slidingly connected with a rhombic wedge-shaped rod 115. The rhomboid wedge-shaped rod 115 cooperates with the sleeve rod 112. A second spring 116 is connected between them.

[0040] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com