Self-adaptive stroke electromagnetic drive surface micro-forging device and its application

An electromagnetic drive and self-adaptive technology, applied in the driving device, electromechanical device, electrical components and other directions of the forging press, can solve the problems of long surface time, low processing efficiency, and increase the complexity of the device structure, so as to improve the processing efficiency, The effect of simplifying the structure and reducing the requirements for positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

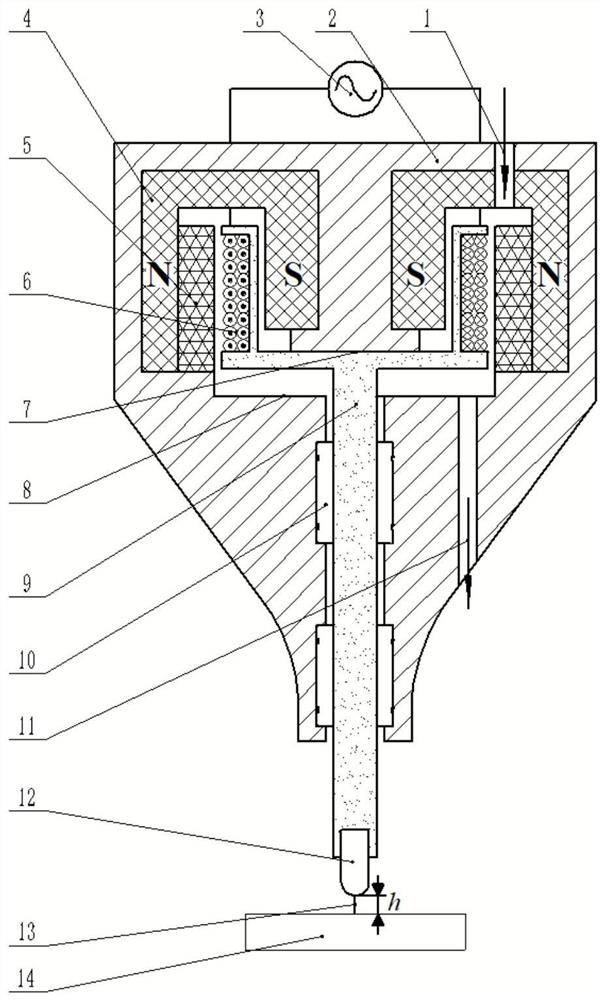

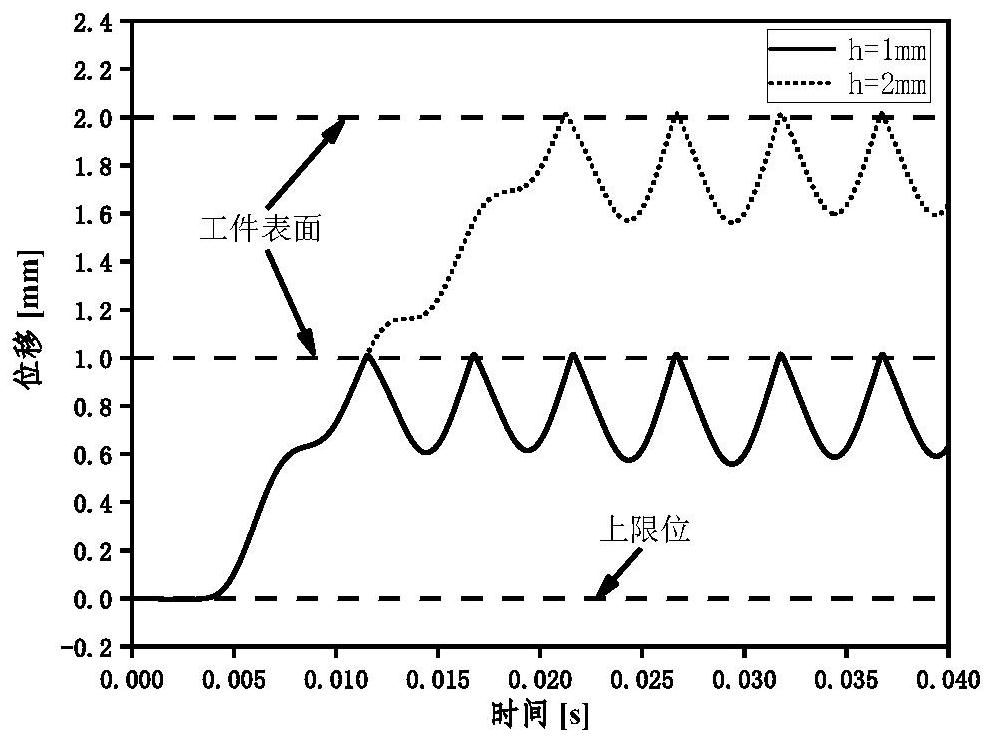

[0017] like figure 1 As shown, this embodiment relates to an electromagnetic surface micro-forging device, including: a frame 2, a magnetic field generating device and a mover arranged therein, wherein the mover includes a mover coil 6, a guide shaft 9, an impactor Head 12; the magnetic field generating device includes a yoke 4 and a permanent magnet 5 disposed therein.

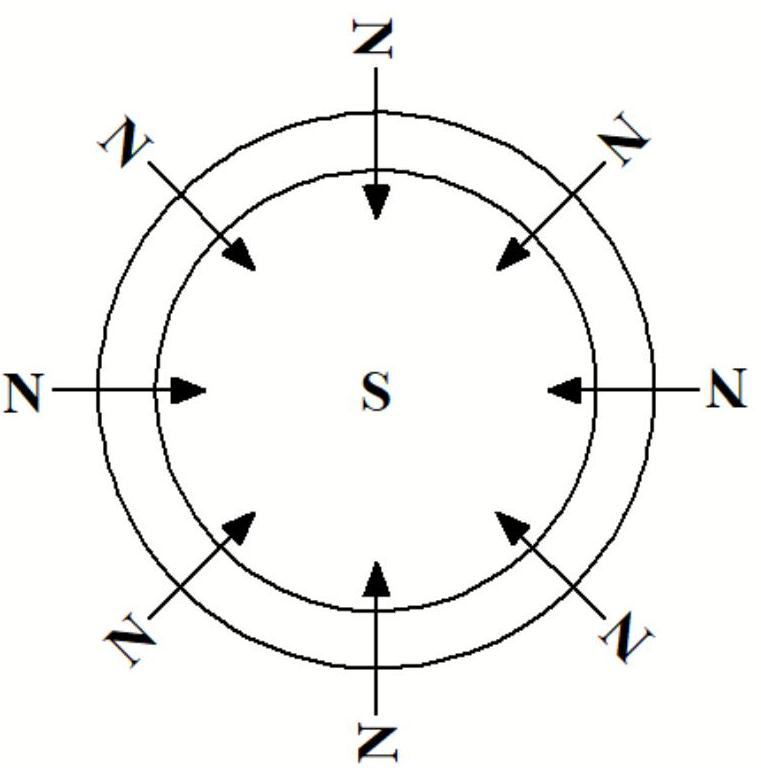

[0018] like figure 2 As shown, the permanent magnet 5 is a radiation magnetized permanent magnet ring, and the yoke 4 is generally a soft magnetic material, which can transmit magnetic lines of force. The two work together to generate a horizontal magnetic field around the mover coil 6. When the current enters, the coil is acted by the ampere force to drive the mover to move along the axial direction.

[0019] The frame is provided with an upper limit 7 and a lower limit 8 to limit the displacement range of the mover.

[0020] The rack is provided with an air inlet 1 and an air outlet 11 for circulating c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com