Aluminum bar casting cooling equipment

A technology of cooling equipment and aluminum rods, which is applied in casting equipment, metal processing equipment, casting molten material containers, etc., can solve the problems of low cooling efficiency, achieve the effects of fast flow speed, convenient water outlet temperature, and reduced resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

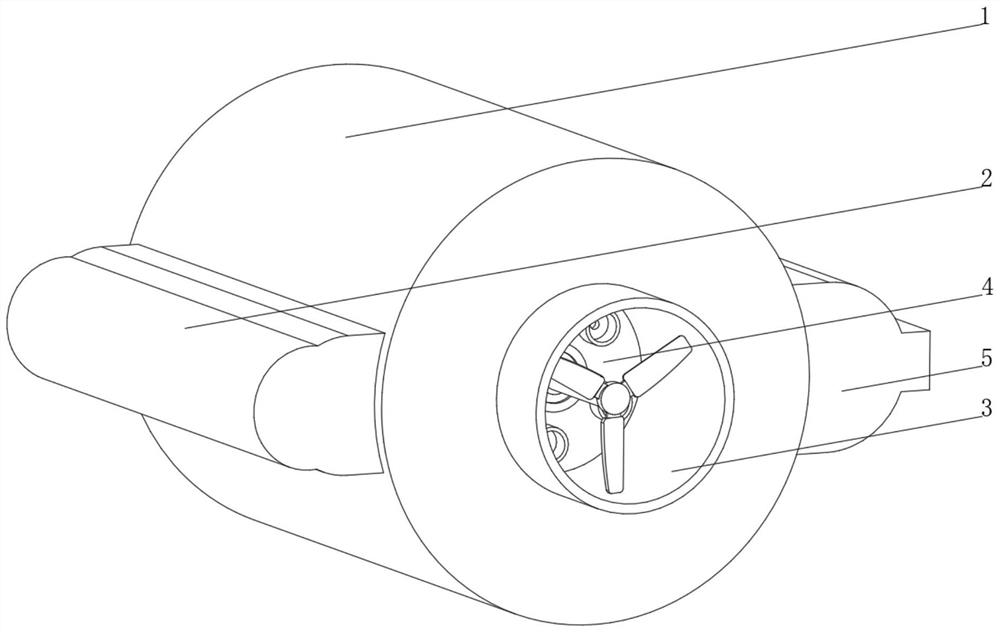

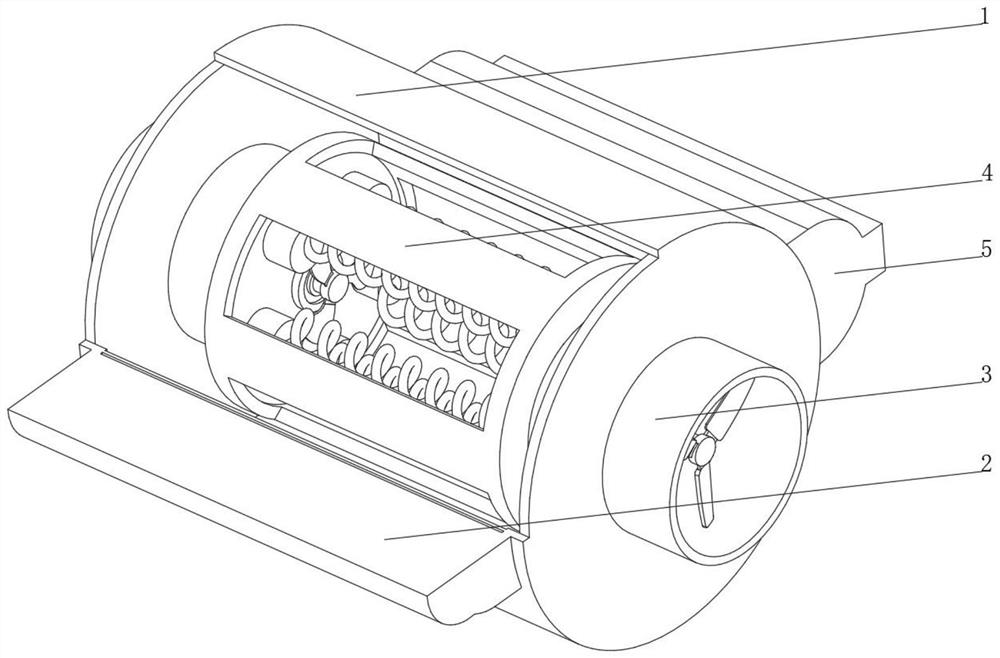

[0034] see Figure 1-3 , the present invention provides a technical solution: an aluminum rod melting and casting cooling equipment, specifically comprising:

[0035] A fixed outer cylinder 1, one side of the fixed outer cylinder 1 is fixedly connected with a cooling fan 2, and both ends of the fixed outer cylinder 1 are penetrated and communicated with a water delivery pipe 3

[0036] Cooling device 4, the cooling device 4 is arranged inside the fixed outer cylinder 1, and both ends of the cooling device 4 communicate with the water delivery pipe 3;

[0037] An air outlet device 5, the air outlet device 5 is arranged on one side of the fixed outer cylinder 1, and the air outlet device 5 communicates with the fixed outer cylinder 1 side;

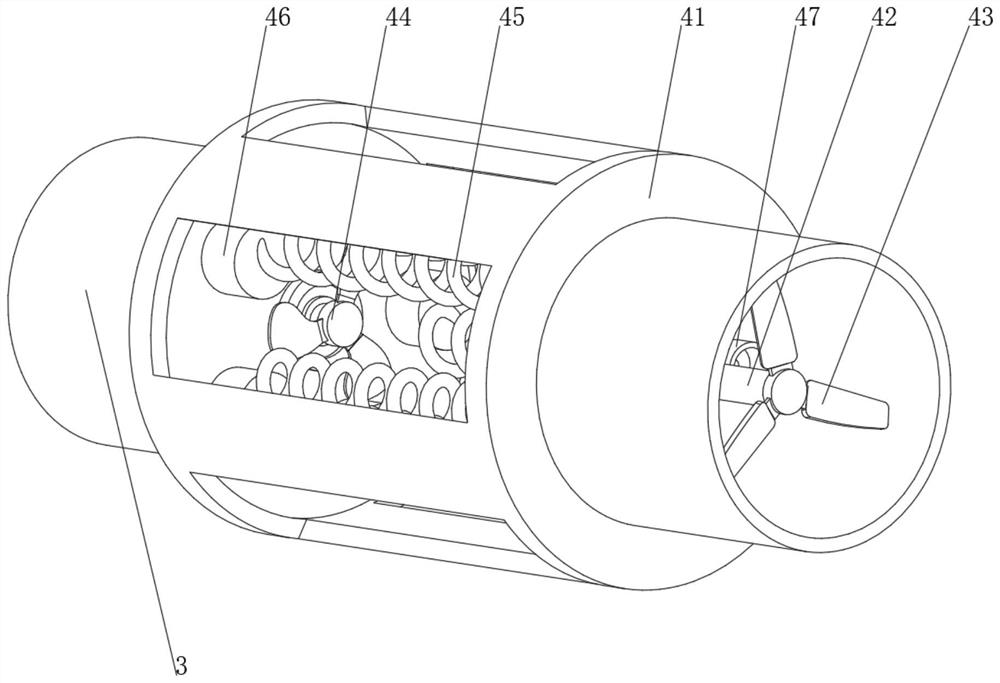

[0038] Cooling device 4 comprises:

[0039] Cooling cylinder 41, the side of the cooling cylinder 41 is provided with air holes, the two ends of the cooling cylinder 41 are connected to the connecting shaft 42 through bearing rotation, and...

Embodiment 2

[0043] see Figure 1-4 On the basis of Embodiment 1, the present invention provides a technical solution: the adjusting device 46 includes a threaded sleeve 461, the inner wall of the threaded sleeve 461 is provided with a sealing groove 462, and the inner wall of the sealing groove 462 is connected with a sealing ring 464 through an air bag 463, and the threaded sleeve 461 An adjusting pipe 465 is threadedly connected to the inner wall of the sleeve 461 , the threaded sleeve 461 runs through the cooling cylinder 41 and is fixedly connected with the cooling cylinder 41 , and one end of the adjusting pipe 465 communicates with the spiral pipe 45 .

[0044] An adjustment device 46 is provided, and the adjustment tube 465 is rotated, the adjustment tube 465 moves inside the threaded sleeve 461 and drives the spiral tube 461 to expand and contract, which facilitates changing the bending degree of the spiral tube 461 and changing the circulation distance of hot water inside the cool...

Embodiment 3

[0046] see Figure 1-5 , On the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the air outlet device 5 includes an air outlet housing 51, the top and bottom of the inner wall of the air outlet housing 51 are fixedly connected with elastic components 52, and the elastic components 52 are far away from the air outlet housing 51 A sealing strip 53 is fixedly connected to one end of the sealing strip 53, and both ends of the sealing strip 53 extend to the inner wall of the air outlet shell 51. One side of the air outlet shell 51 is connected with an air outlet nozzle 54, and one side of the air outlet shell 51 is connected with the fixed outer cylinder 1. The elastic component 52 includes Fixed rod 521 and arc-shaped spring sheet 522, fixed rod 521 is provided with two groups, and arc-shaped spring sheet 522 is provided with several groups and is evenly distributed between two groups of fixed rods 521, and the fixed rod 521 two ends of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com