Machining technology for aluminum alloy rod for extrusion

An aluminum alloy rod and processing technology technology, applied in the field of aluminum alloy processing, can solve the problems that the aluminum alloy rod affects the surface roughness, the purity of the aluminum alloy rod is not high, and the processing technology is rough, so as to improve the mass production and high production efficiency. , to ensure the effect of processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with accompanying drawing:

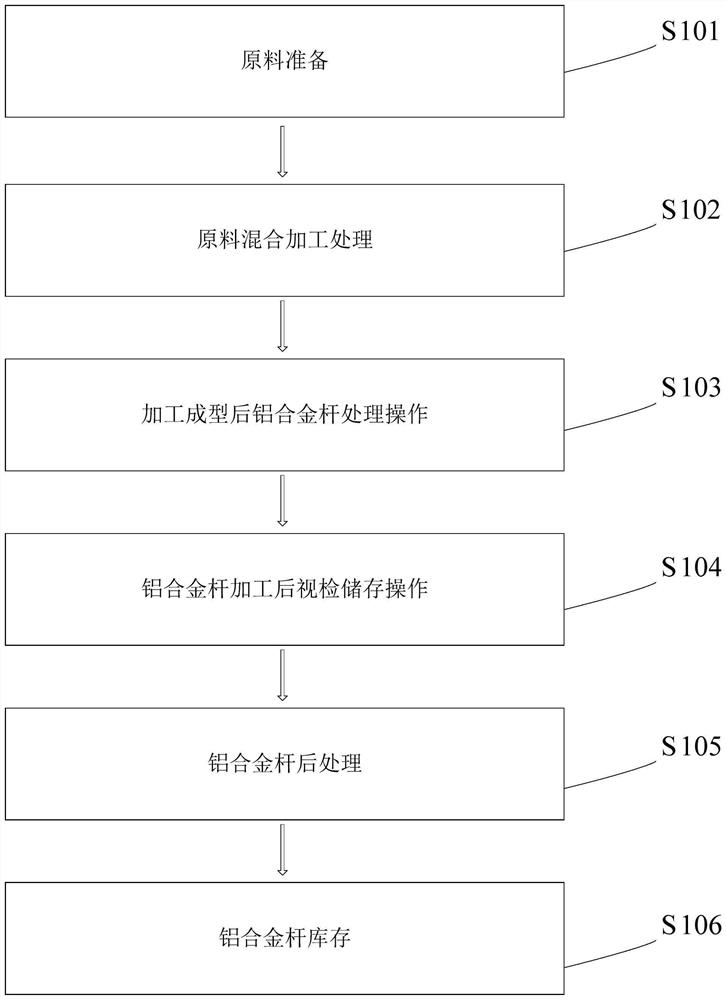

[0035] as attached figure 1 As shown, the processing technology for the aluminum alloy rod for extrusion of the present invention specifically includes the following steps:

[0036] S101: Raw material preparation, prepare 0.3-0.5% iron, 0.2-0.3% copper, 0.5-0.8% steel, 2.0-3.0% silicon, and the rest is aluminum, process the aluminum material, and remove the aluminum material raw material through a vibrating screen Impurities, and then adsorb and remove iron impurities in the aluminum raw materials by permanent magnet blocks, the filtered impurities are collected through nylon mesh bags, and the filtered aluminum raw materials are collected to prepare for the melting process;

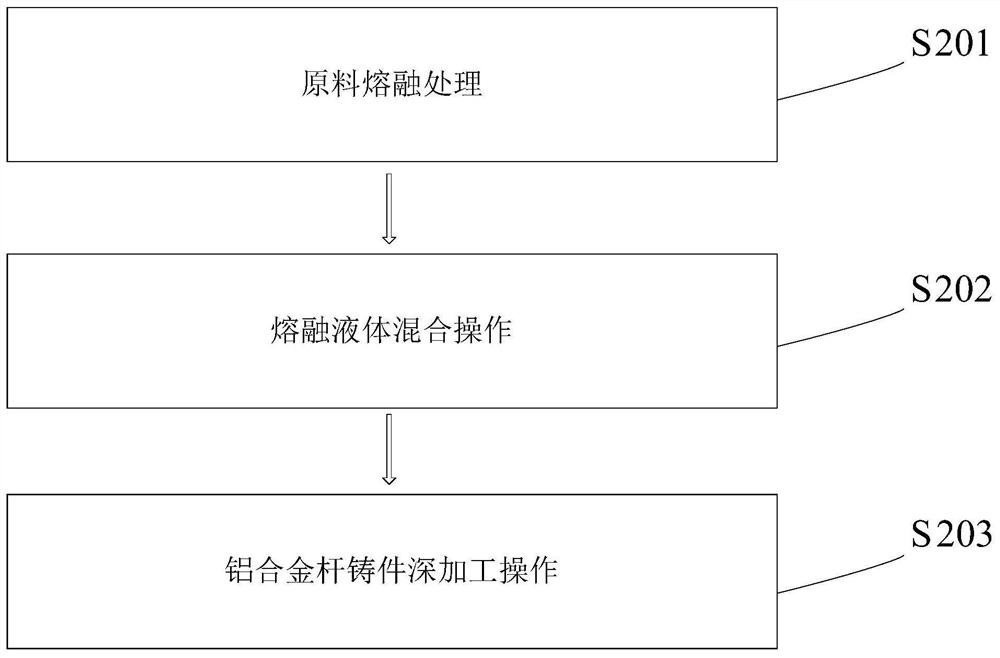

[0037] S102: Mixing and processing of raw materials, if attached figure 2 As shown, the specific operation includes the following steps:

[0038] S201: Raw material melting treatment, pour iron, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com