Intelligent safety tool warehouse-in and warehouse-out management system

A technology of safety equipment and management system, which is applied in the field of intelligent safety equipment entry and exit management system, which can solve the problems of ventilation and disinfection, record information, scattered asset information, time-consuming, etc., and achieve simple structure of entry and exit, and efficiency of entry and exit Fast, improve the effect of storage quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0069] Example: Please refer to Figure 1 to Figure 13 :

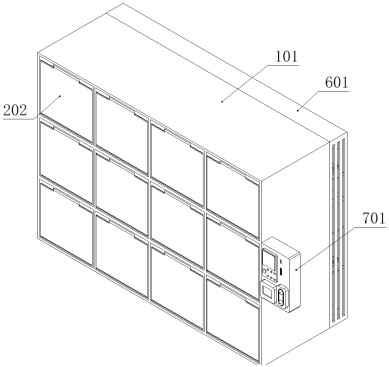

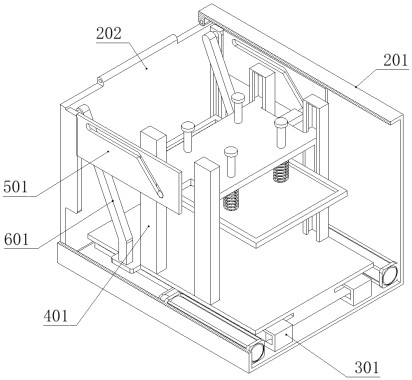

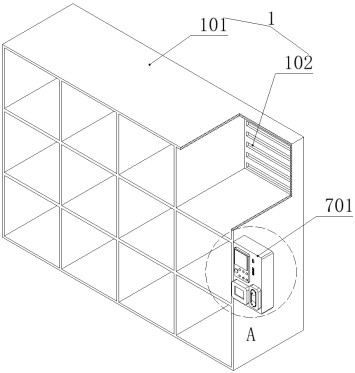

[0070] The present invention proposes a management system for intelligent safety tools in and out of the warehouse, including a box frame device 1; three rows of storage devices 2 are installed on the box frame device 1; mobile devices 3 are respectively installed inside the three rows of storage devices 2; Positioning and degerming devices 4 are fixedly connected respectively; positioning guide parts 5 are respectively fixed and connected to the two sides of the three rows of storage devices 2; two driving parts 6 are fixedly connected to the three rows of moving devices 3 respectively; A control device 7 is fixedly connected; a cleaning device 8 is fixedly connected to the rear side of the box frame device 1; the control device 7 includes: a main control box 701, which is fixedly connected to the side of the installation box frame 101; the main control box 701 is electrically connected Human-computer interaction ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com