Butadiene-acrylonitrile rubber with low hardness and high acrylonitrile content and preparation method thereof

A technology for nitrile rubber and acrylonitrile, which is applied in the field of nitrile rubber with low hardness and high acrylonitrile content and its preparation field, can solve the problems of flow marks, pocket gas, hardness rise and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A nitrile rubber with low hardness and high acrylonitrile content, which comprises 40-45 parts of nitrile rubber, 2-3 parts of zinc oxide, 1-2 parts of anti-aging agent, 5-10 parts of carbon black, and inorganic 20-25 parts of filler, 10-15 parts of softener, 2-5 parts of liquid nitrile rubber, 0.2-0.5 parts of sulfur, and 1-2 parts of accelerator.

[0032] As a preferred mode in this embodiment, according to parts by weight, 44.7 parts of nitrile rubber, 2.23 parts of zinc oxide, 1.3 parts of anti-aging agent, 8.9 parts of carbon black, 22.3 parts of inorganic filler, 13.4 parts of softening agent, liquid butyl 4.5 parts of nitrile rubber, 0.4 parts of sulfur, and 1.5 parts of accelerator.

[0033] Wherein the nitrile rubber is a copolymer of acrylonitrile and butadiene, and the acrylonitrile content is greater than 40%.

[0034] The anti-aging agent is anti-aging agent RD or anti-aging agent 4010NA.

[0035] Carbon black is fast extrusion carbon black.

[0036] The...

Embodiment 2~3

[0044] Embodiment 2~3 and comparative example 1,2

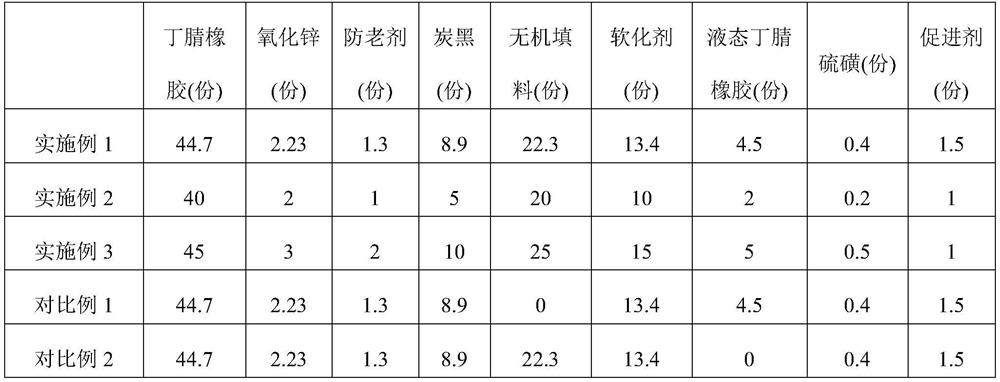

[0045] The difference from Example 1 is only that the percentages of each composition are different, and the specific composition percentages are shown in Table 1 below:

[0046] Table 1 is the composition percentage of embodiment 1~3 and comparative example 1,2

[0047]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com