600 MPa-grade vanadium-niobium-titanium-nitrogen composite reinforced steel bar and smelting method thereof

A smelting method and steel bar technology, applied in the field of 600MPa vanadium-niobium-titanium-nitrogen composite strengthened steel bar and its smelting field, can solve the problems of insufficient precipitation strengthening effect, high consumption of vanadium-nitrogen alloy, low utilization rate of V, etc., and achieve high strength Yield ratio and ultimate strength, enhanced microalloying, cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

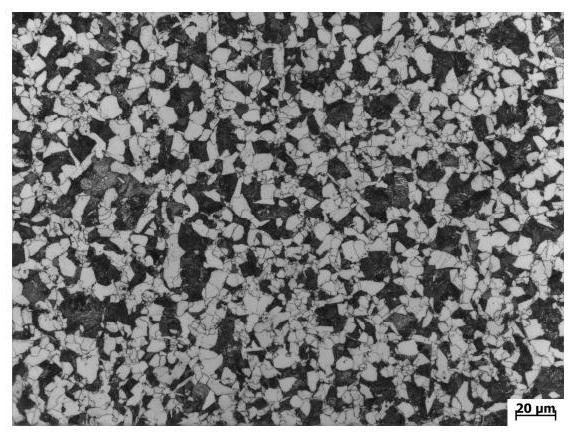

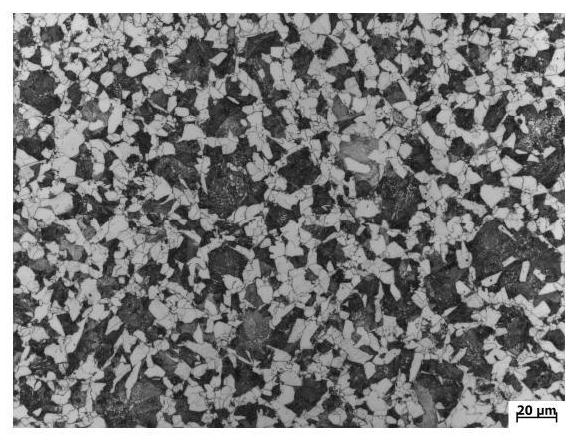

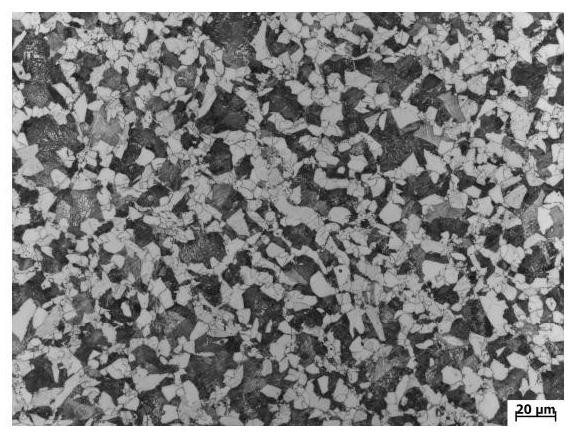

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

[0017] The method for smelting 600MPa-grade vanadium-niobium-titanium-nitrogen composite strengthened steel bar according to the present invention adopts smelting process for smelting, and in the steel tapping process of converter smelting, according to the amount of 1.80~1.93kg / t steel, the N content is added to be 16%. Vanadium-nitrogen alloy FeV with V content of 77%, the balance being Fe and unavoidable impurities 77 N 16 , and according to the amount of 0.21-0.37kg / t steel, add ferroniobium with Nb content of 63.0-65wt%, add titanium wire with Ti content of 67wt%, and control the Ti / N ratio of molten steel between 3-3.57 .

[0018] In the prior art, when the 600MPa steel bar is produced and smelted, microalloying vanadium and nitrogen by adding vanadium-nitrogen al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com