Slidable connection method for light wallboard infilled wall and structure main body and connection assembly of connection method

A light-weight wall panel and structural main body technology, applied to building components, walls, building structures, etc., to achieve the effects of clear structural force, guaranteed reliability, and clear force transmission routes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

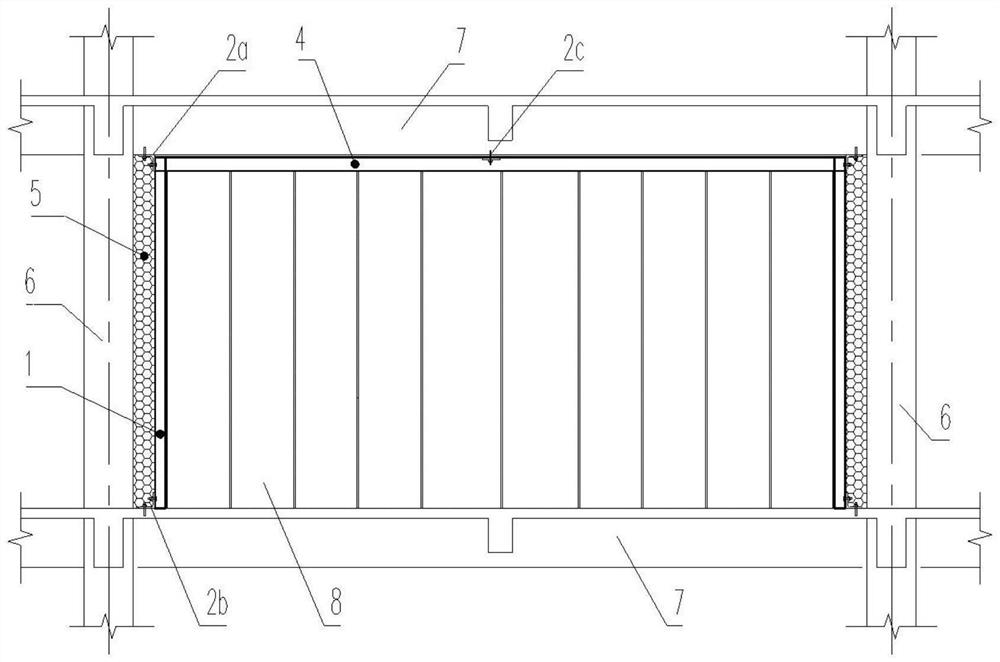

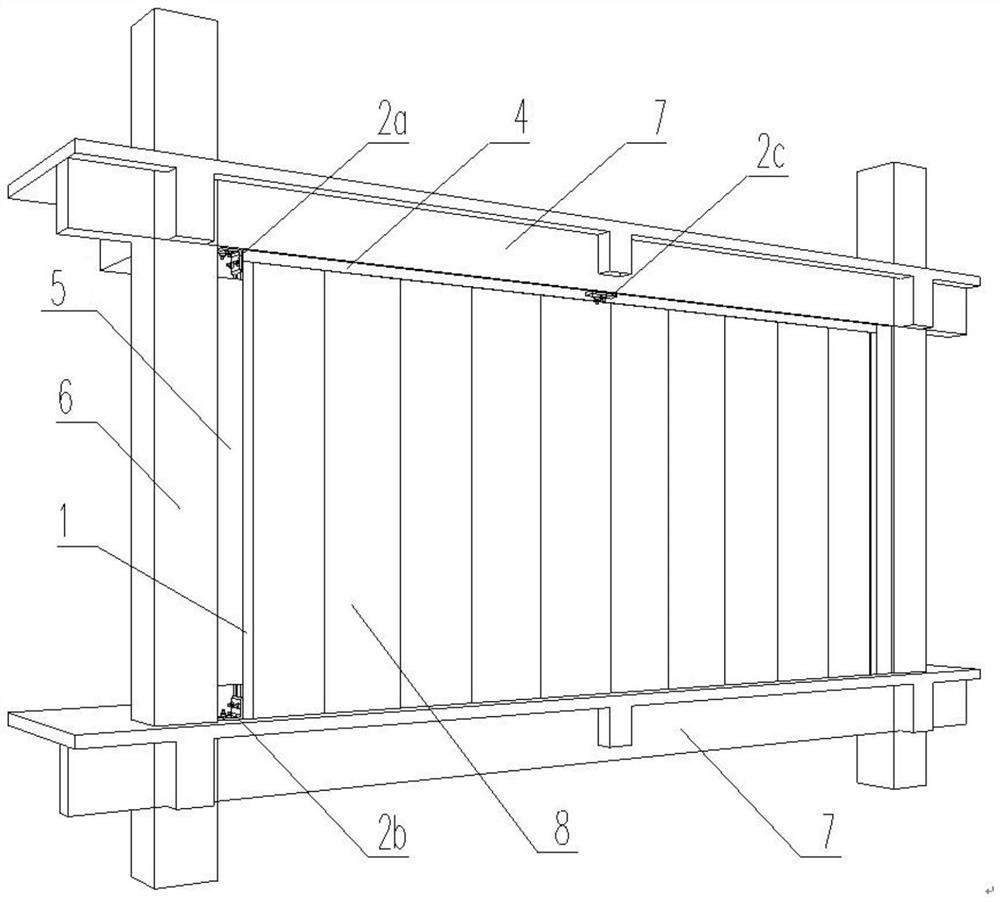

[0026] refer to Figure 1 ~ Figure 3 As shown, a method for slidably connecting a lightweight wallboard filling wall and a structural main body, including a frame 1, a first sliding connector 2a, a fixed connector 2b, a second sliding connector 2c, a horizontal beam 4, a flexible The filling assembly 5, the vertical structural member 6, the transverse structural member 7 and the lightweight wallboard filling wall 8, the flexible filling assembly 5 includes the thermal insulation and fireproof material 5a, the ointment caulking material 5b and the shell 5c.

[0027] The vertical vertical structural members 6 and the horizontal transverse structural members 7 are arranged alternately to form a rectangular wall hole, and the lightweight wallboard filling wall 8 is located in the wall hole. In this application, the slidable connection component is used to realize that the light-weight wall panel filling wall can slide with the structural main body in the plane, and is stable outsi...

Embodiment 2

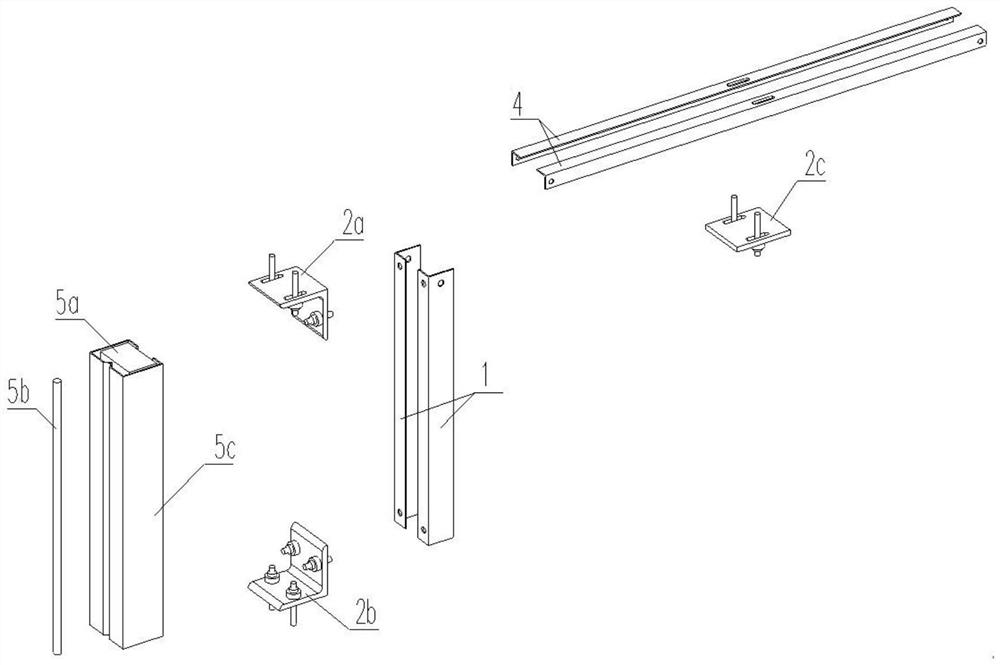

[0034] refer to image 3 As shown, a connection assembly for the above-mentioned slidable connection method between a lightweight wallboard filling wall and a structural main body includes a frame 1, a first sliding connection 2a, a fixed connection 2b, a second sliding connection 2c, The horizontal beam 4 and the flexible filling component 5, the flexible filling component 5 includes the thermal insulation and fireproof material 5a, the ointment caulking material 5b and the shell 5c.

[0035] The frames are two groups arranged symmetrically on the left and right, and the horizontal beams 4 are connected by bolts between the left and right frames. Specifically, each set of frame 1 is two front and rear angle steels, and the lying beam 4 is two front and rear angle steels. The angle steels can limit the lateral direction of the lightweight wallboard infill wall, and can also protect the outer surface of the lightweight wallboard infill wall. Carry out limit protection.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com