Tunneling machine and auxiliary excavation device for tunneling machine

A technology for roadheaders and driving devices, which is applied in the field of tunnel boring machines and auxiliary excavation devices for roadheaders, can solve problems such as poor stability of crushing heads, and achieve the effects of improved stability, good stability, and convenient installation and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

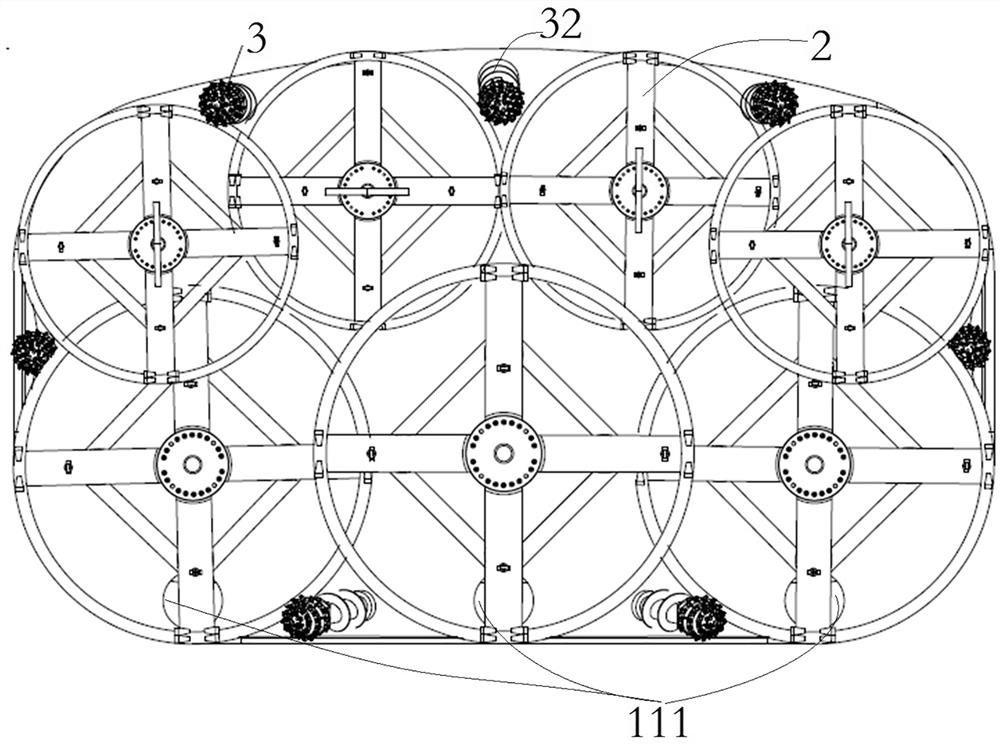

[0060] The tunnel boring machine of the present invention is a non-circular tunnel boring machine, which is applied to the excavation of tunnels with rectangular sections, horseshoe-shaped sections or other special-shaped sections (non-circular sections).

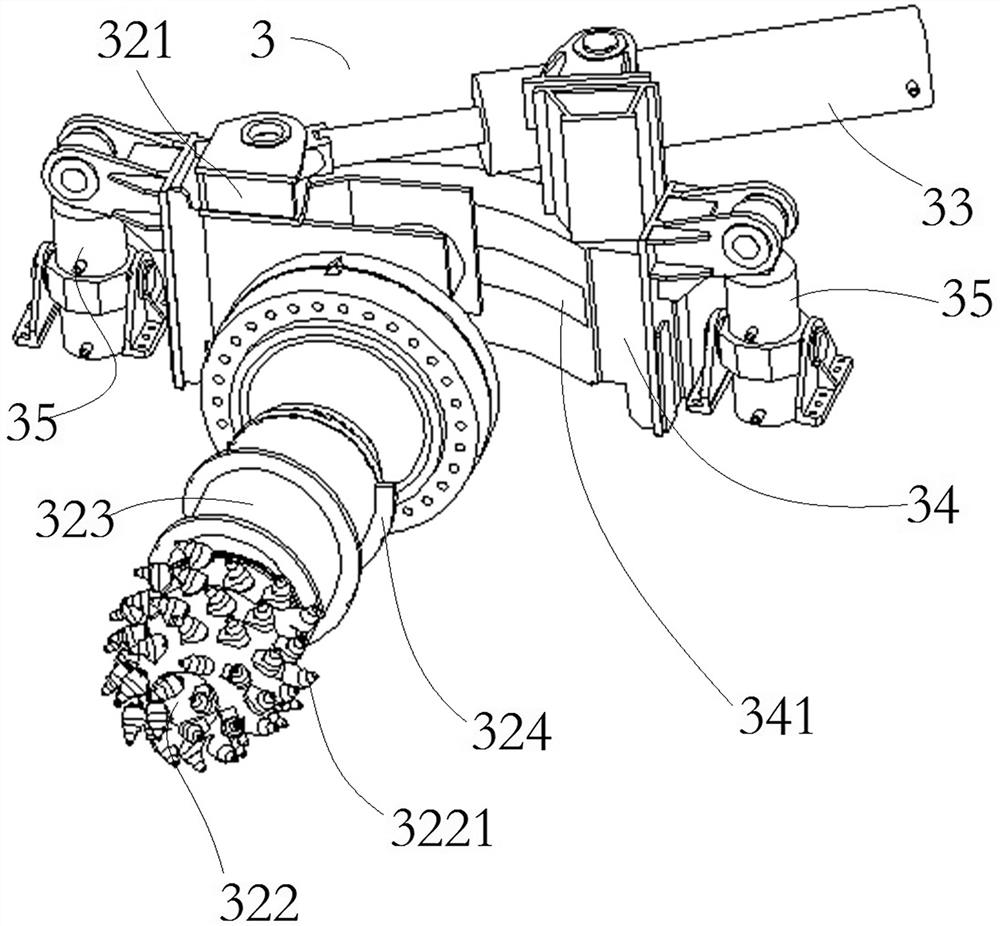

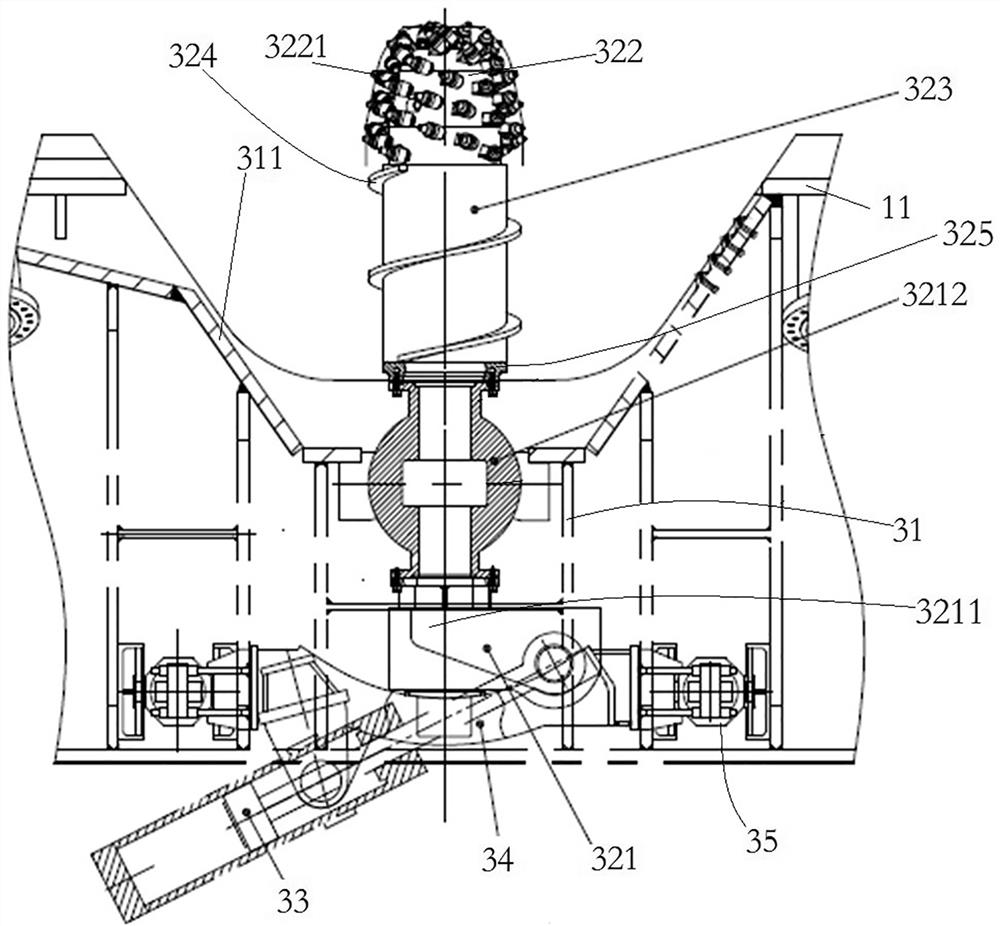

[0061] like Figure 1 to Figure 5 As shown, the non-circular tunnel boring machine includes a frame, a driving cutterhead 2 and an auxiliary excavation device 3 for the roadheader, and the auxiliary excavation device 3 for the roadheader includes a mount 31 installed on the frame, a crushing device 32, Swing arm drive mechanism. The frame includes a boring machine partition 11 arranged on the rear side of the boring cutter head 2 . The mounting seat 31 is fixed on the dividing plate 11 of the roadheader.

[0062] The crushing device 32 includes a swing arm 321 , a crushing head 322 rotatably arranged on the swing arm 321 , a driving device for driving the crushing head 322 to rotate, and a crushing rod connecting the crus...

specific Embodiment 2

[0084] The specific embodiment 2 of the tunnel boring machine of the present invention only differs from the foregoing embodiments in that:

[0085] In this embodiment, the space inside the roadheader is limited, and the telescopic drive cylinder cannot be arranged. like Figure 6 to Figure 8 As shown, in this embodiment, the swing arm drive cylinder 33 is located at the front side of the guide seat 34 . The guide seat adjustment structure includes an adjustment seat 36, the adjustment seat 36 has an adjustment surface 361, the guide seat 34 is provided with a fitting surface that fits with the adjustment surface, and the attitude of the guide seat 34 is adjusted by changing the posture of the adjustment surface 361 of the adjustment seat 36 . The adjustment seat 36 is fixed with the installation seat 31 and the guide seat 34. In this embodiment, the adjustment surface 361 is an inclined surface. By replacing the adjustment seat 36 and changing the inclination angle of the ...

specific Embodiment 5

[0089] Concrete embodiment 5 of the tunnel boring machine of the present invention, the driving mechanism of the guide seat in the above embodiment drives the guide seat to move in a circular arc around the spherical center of the spherical joint structure, the difference between this embodiment and the above-mentioned embodiment is only: the driving mechanism of the guide seat Drive the guide seat to move in a straight line, and at this time, a certain angle of swing should be allowed between the guide groove on the guide seat and the swing arm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com