Automatic inductor winding machine and cross winding method applied to winding machine

An automatic winding machine and automatic winding technology, which is applied in the manufacture of inductors/transformers/magnets, circuits, coils, etc., can solve the problems of requiring more manpower, low efficiency, and the inability to realize the cross-winding method, so as to ensure the production The effect of quality and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

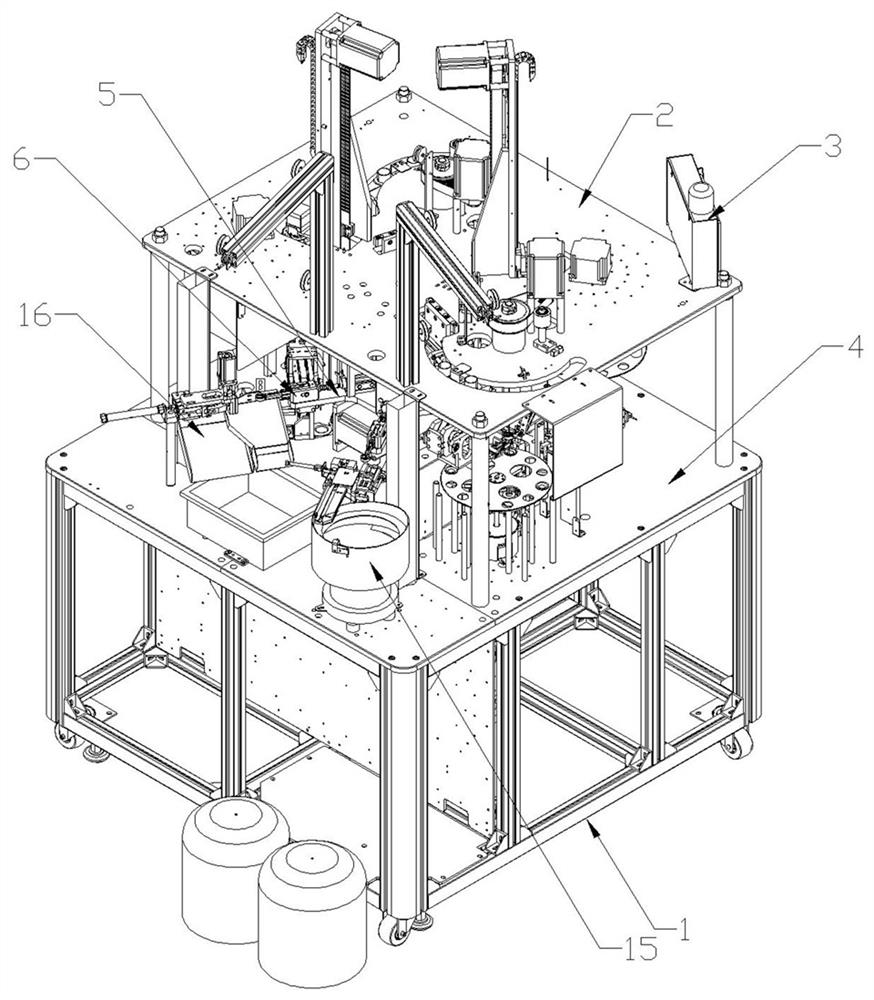

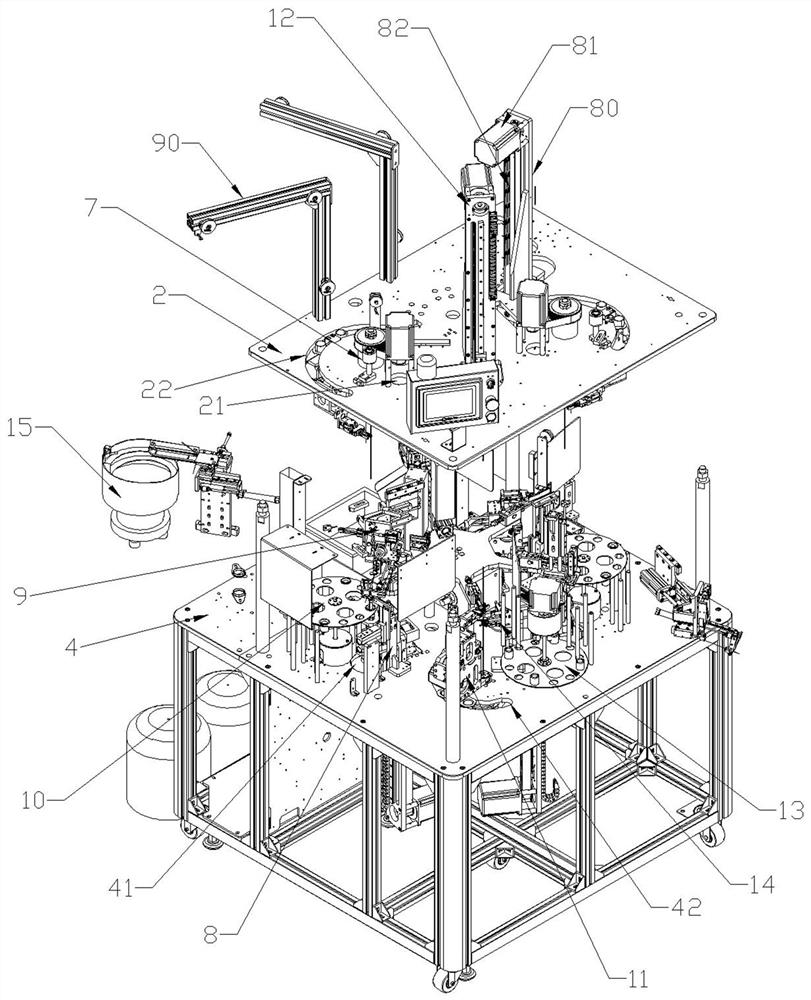

[0038] Such as figure 1 , figure 2 and image 3 As shown, the present invention includes a frame 1, a control panel 3 arranged on the top plate 2 of the frame 1, a feeding turntable 5 is rotated on the mounting plate 4 of the frame 1, and a rotating disk 5 is arranged on the mounting plate 4 around the The feeding turntable 5 is sequentially provided with a feeding mechanism, at least one set of automatic winding modules and a blanking mechanism, the automatic winding modules include a first winding station and a second winding station, and the feeding The turntable 5 is provided with a number of gripping manipulators 6, and the setting positions of the gripping manipulators 6 correspond to the feeding mechanism, at least one set of the automatic winding modules and the feeding mechanism, and the control panel 3 is electrically connected with the feeding turntable 5, the feeding mechanism, at least one set of the automatic winding module, the feeding mechanism and the clamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com