Integrated wear-free low-impedance switch cabinet air chamber based on main switch loop

A wear-free, main switch technology, applied in the field of switchgear, can solve the problems of enhanced process difficulty in the remanufacturing process, large volume of air-insulated switchgear, and damage to the structural integrity of the air chamber, so as to preserve the structural integrity and reduce assembly work The effect of increasing the quantity, improving the versatility and the degree of standardization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is further described in conjunction with the following examples.

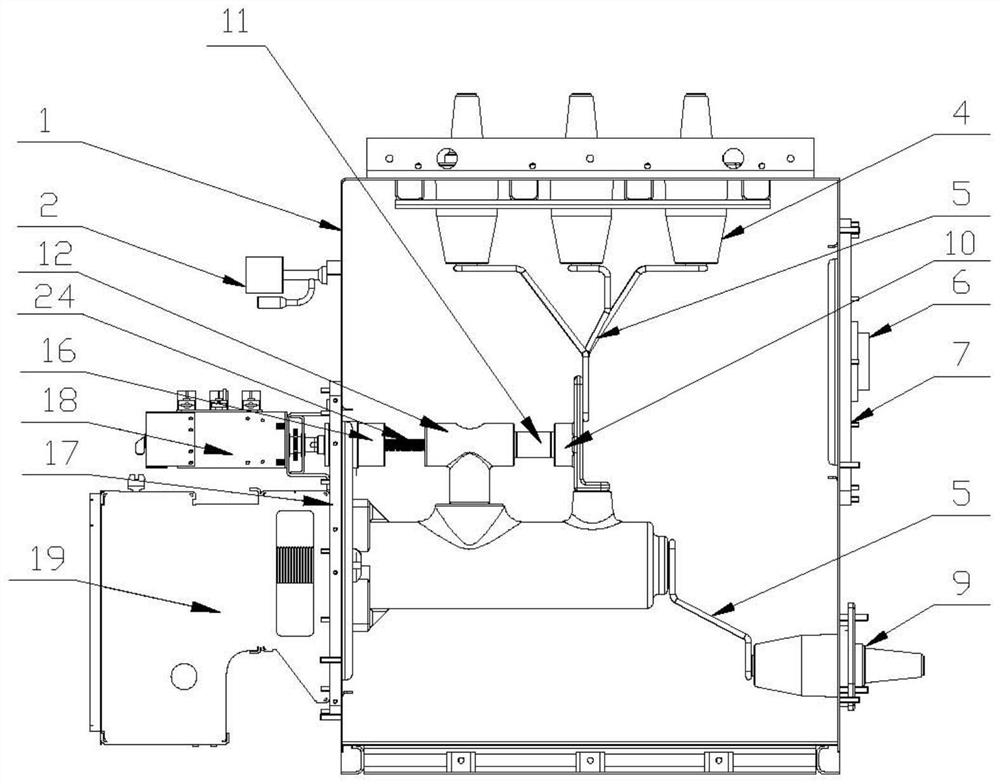

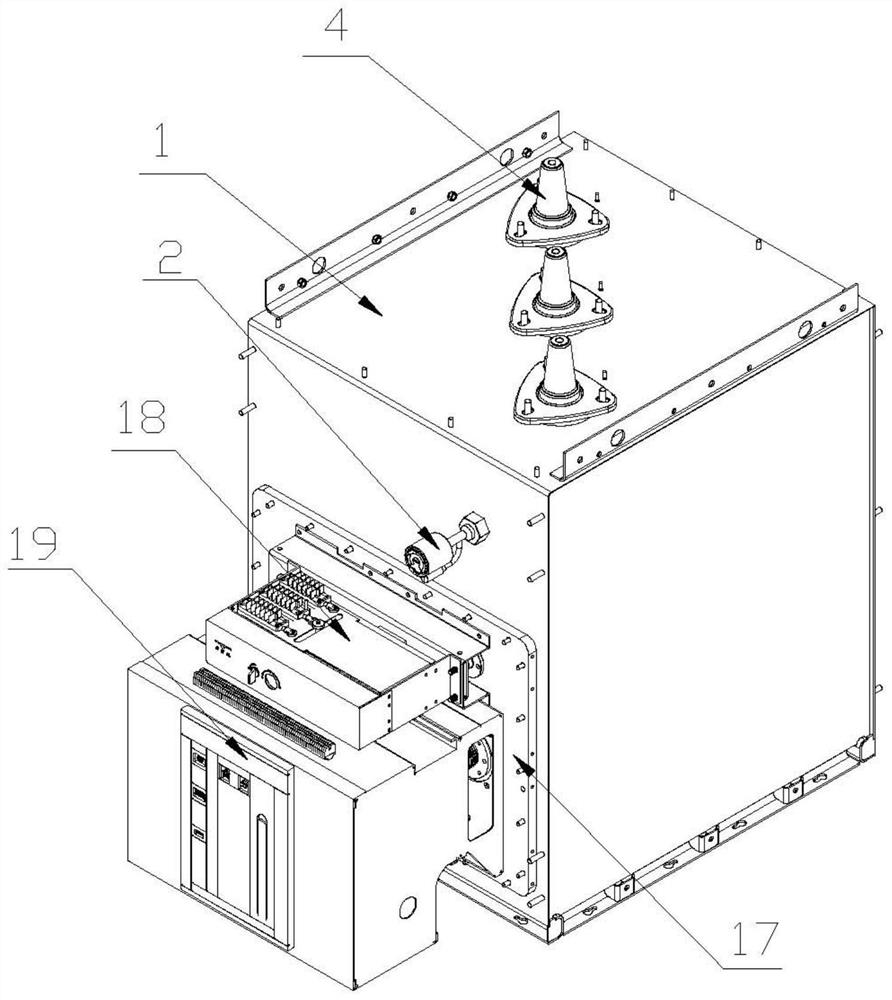

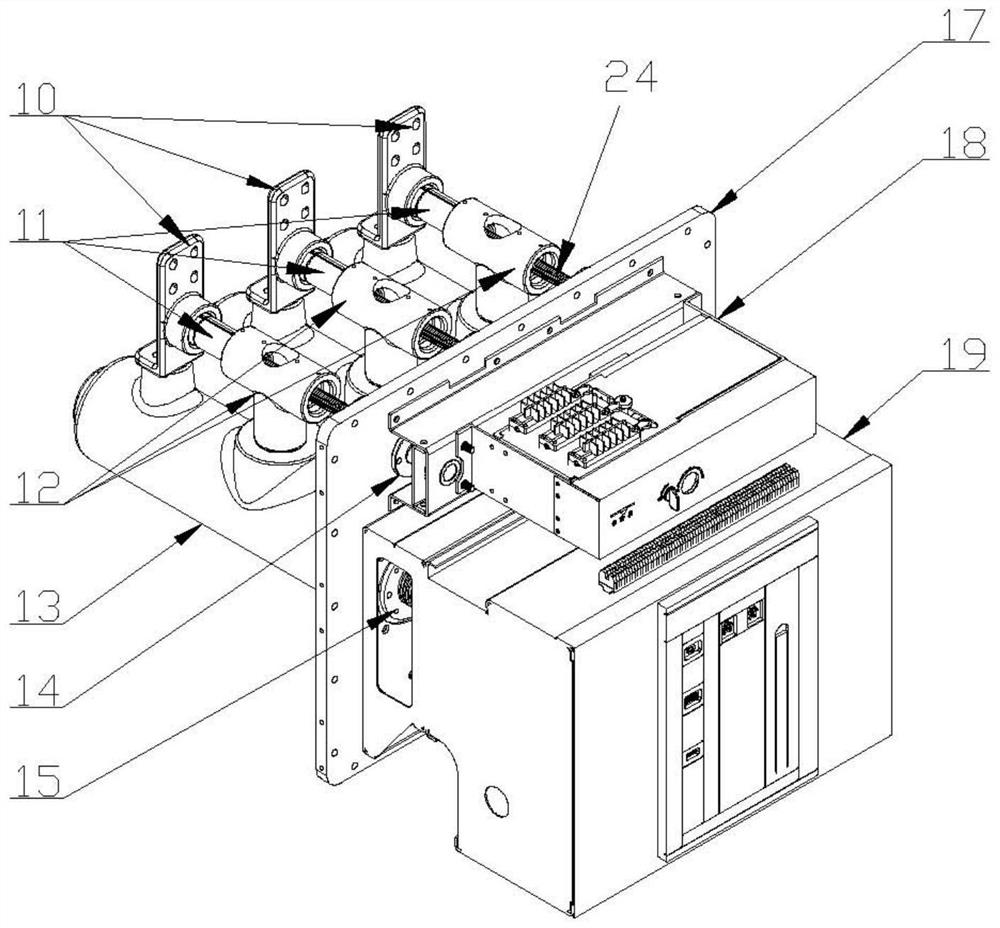

[0027] For a specific implementation of the gas chamber of a switchgear based on the integration of the main switch circuit without wear and low impedance of the present invention, please refer to figure 1 The air chamber includes an air chamber housing 1, and the left side, right side and upper side of the air chamber housing 1 are respectively sealed and fixed with a reference flange 17, a second outer tapered sleeve 9 and a first outer tapered sleeve 4. It should be noted that the side of the gas chamber housing 1 where the reference flange 17 is installed is provided with an opening for inserting the flange of the reference flange 17, and the skirt of the reference flange 17 is fixed on the outer surface of the gas chamber housing 1 by bolts. , using the locking force of the bolts to make the reference flange 17 close to the left side of the air chamber housing 1 . In order to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com