Liquid crystal antenna panel and manufacturing process thereof

An antenna panel and manufacturing process technology, applied in printed circuit manufacturing, nonlinear optics, laminated printed circuit boards, etc., can solve the problems of low cost, high processing cost, long iterative production cycle, etc., to meet the needs of small batch production, Solve the effect of high processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

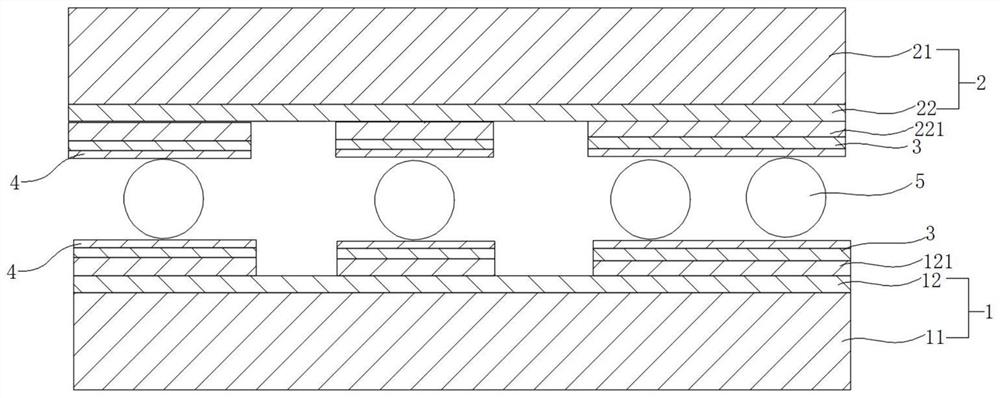

[0036] like figure 1 As shown, a liquid crystal antenna panel includes a first composite substrate 1 and a second composite substrate 2 oppositely arranged, and the first composite substrate 1 and the second composite substrate 1 are connected by a sealing frame between the first composite substrate 1 and the second composite substrate 2. The edge area between the two composite substrates 2 is closed to form a liquid crystal cavity filled with liquid crystal.

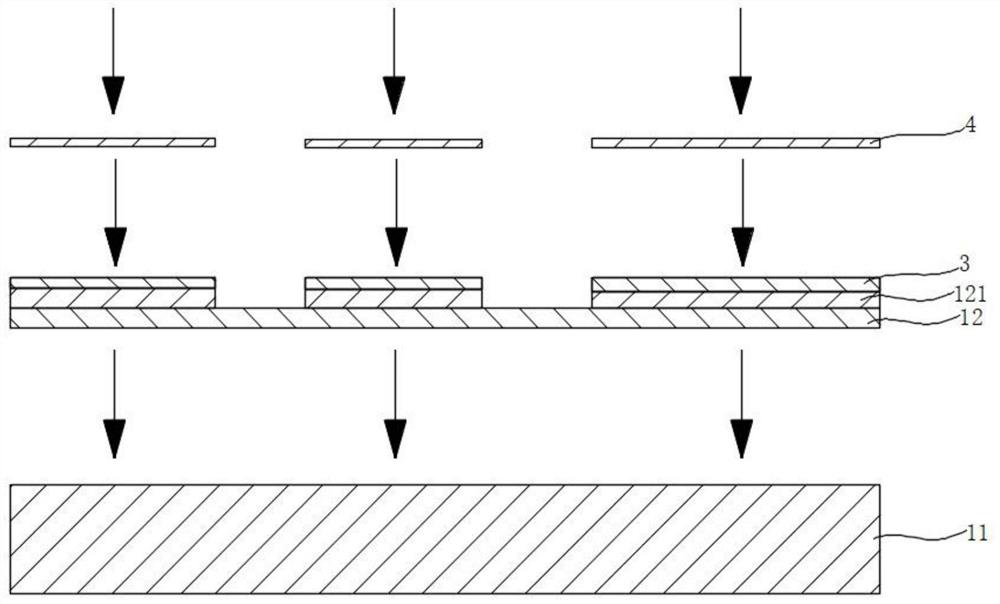

[0037] Please continue to refer to figure 1As shown, in some embodiments, the first composite substrate 1 includes a first flexible circuit board 12 and a first rigid substrate 11 for bonding and fixing with the first flexible circuit board 12; the second composite substrate 2 includes a second The flexible circuit board 22 and the second rigid substrate 21 are used to attach and fix the second flexible circuit board 22 . In some embodiments, the first flexible circuit board 12 includes a copper-clad flexible polyimid...

Embodiment 2

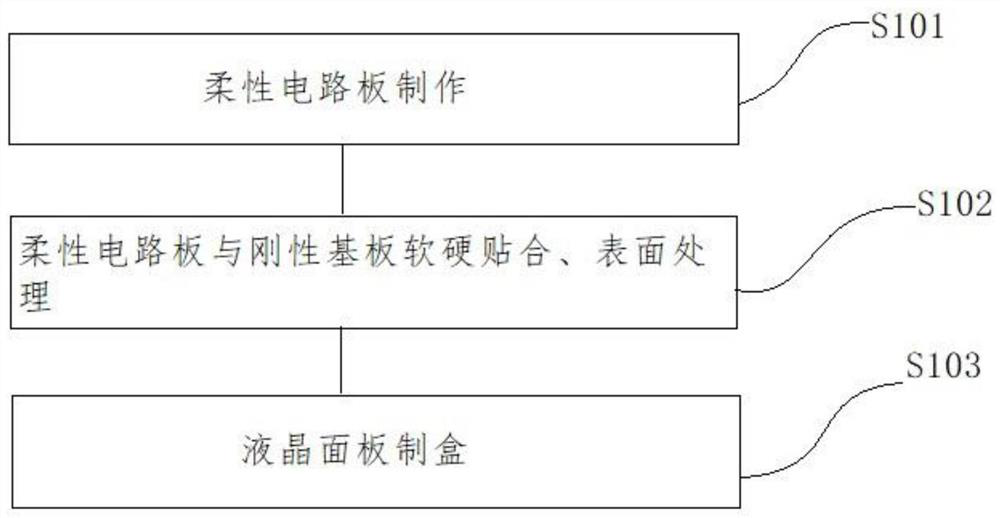

[0045] like image 3 As shown, the present application also relates to a manufacturing process of a liquid crystal antenna panel, comprising the steps of:

[0046] S101. Fabrication of flexible circuit boards;

[0047] S102, flexible circuit board and rigid substrate soft and hard lamination, surface treatment;

[0048] S103. Making boxes for liquid crystal panels.

[0049] Among them, S101, the production of flexible circuit boards includes:

[0050] Step 1. Cutting and cutting, cutting the copper-clad film of the large-area coil raw material, and cutting it to the required size. Here, the size of the flexible circuit board is between 50mm*50mm and 2000mm*2000mm;

[0051] Step 2, drilling, drilling the flexible circuit board, and drilling positioning holes, conduction holes, and test holes according to the circuit design. The positioning holes are used to facilitate subsequent processing and positioning. The first flexible circuit board and / or the first flexible circuit b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com