Systems and processes for suppressing heavy polynuclear aromatic deposition in a hydrocracking process

An aromatic compound, hydrocracking technology, applied in hydrotreating process, chemical instrument and method, chemical/physical process, etc., can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

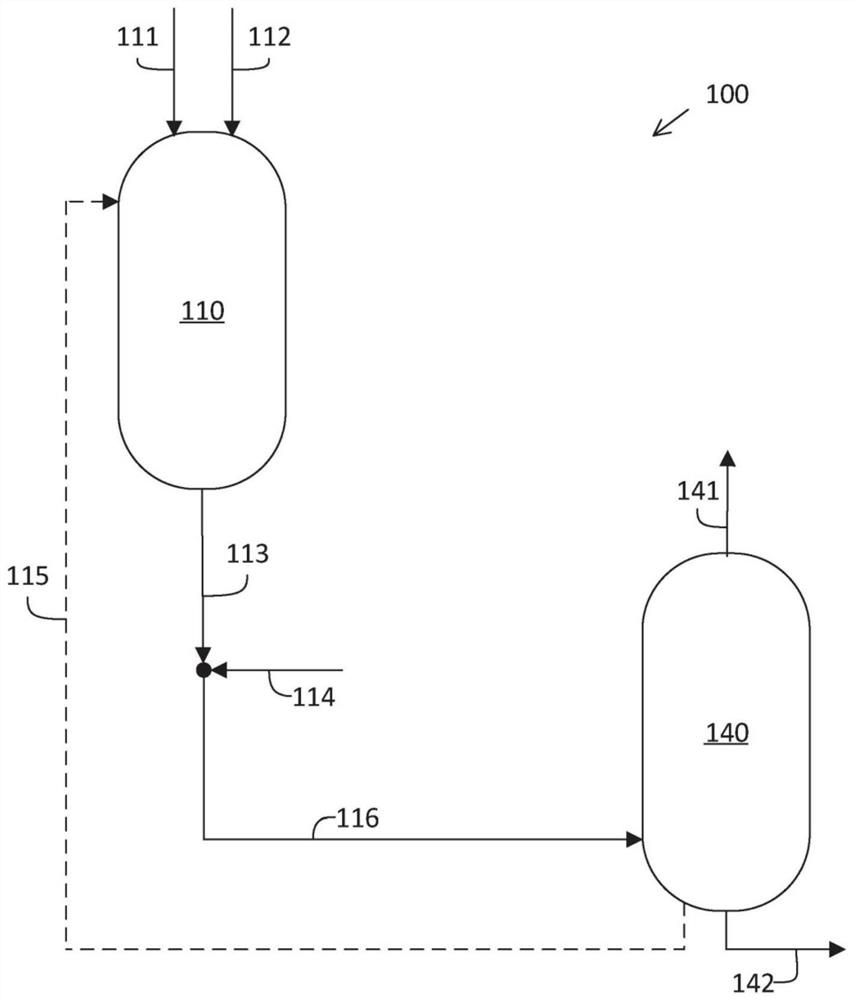

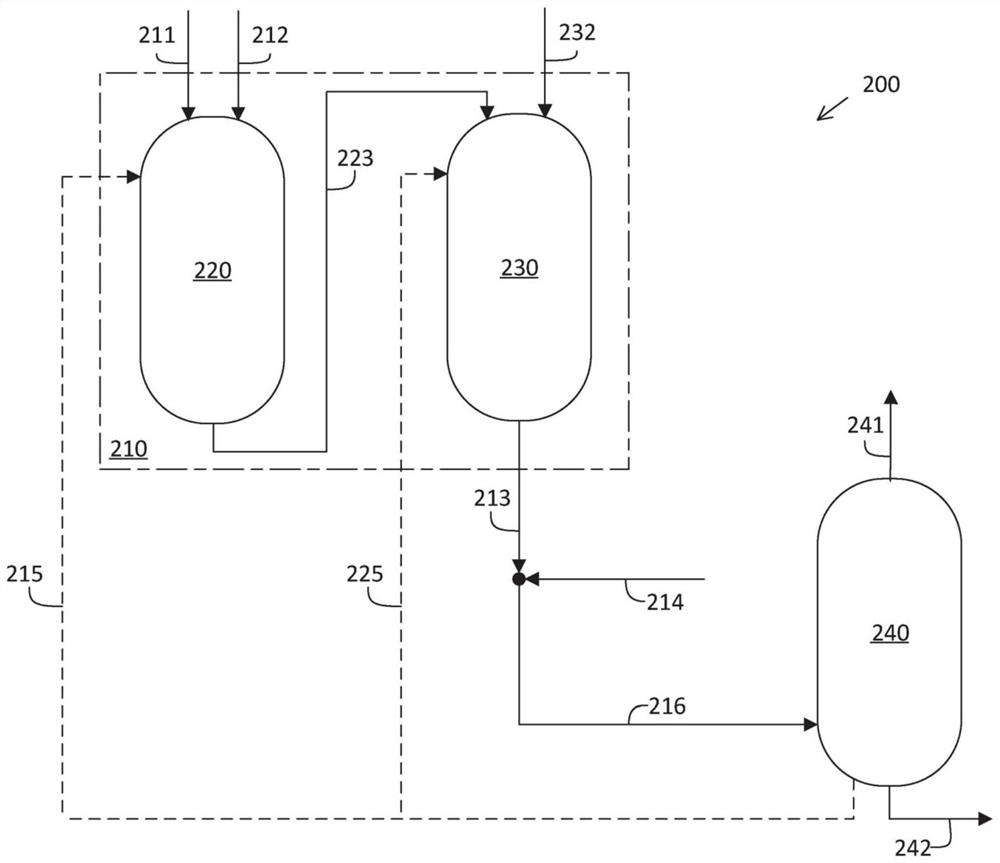

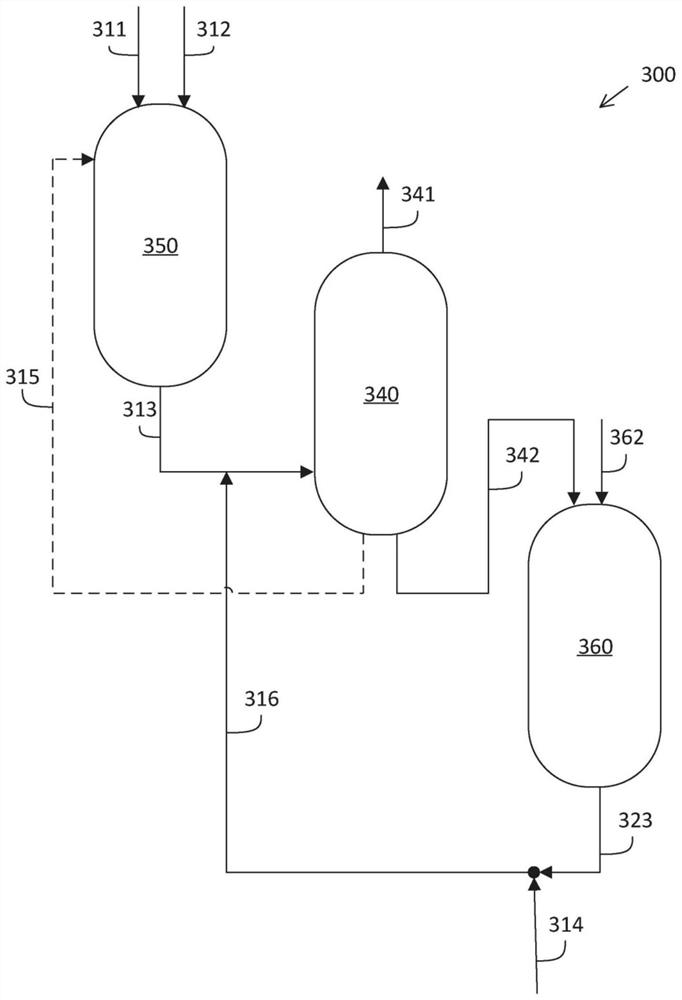

Method used

Image

Examples

Embodiment 1

[0098] A hydrocracking unit configured with a single-pass configuration with recycle, having two reactors, was used to process a feedstock at 30,000 barrels per continuous operating day (BPSD) of 15% A mixture of demetallized oil and 85% vacuum gas oil. The first stage operates at a temperature of 404°C and a hydrogen partial pressure of 115 bar. In the first stage, the conversion under these conditions was 50% by volume. The operating temperature of the second stage was 375° C., resulting in a conversion of 25% by volume, for a total conversion including recycle of 95% by volume. The unit typically yields: 41.2 volume percent total naphtha with a research octane number of 60; and 49.1 volume percent middle distillate with a cetane index (determined using ASTM D976) of 56. Aromatic solvent comprising about 2000 BPSD full range aromatic bottoms from the aromatics recovery complex is mixed with the effluent from the second stage reactor to disperse the HPNA formed in the proce...

Embodiment 2

[0100] A 7.2 g sample containing 1,000 ppm of HPNA from the recycle stream of the hydrocracking unit was mixed with 12.7 g of aromatic solvent from the aromatic bottoms stream of the aromatics recovery complex. Prior to mixing, precipitated HPNA was visually observed in the recirculation flow as particles in the recycle flow and as deposits on the walls of the vials containing the samples. After mixing the aromatic solvent and the recycle stream sample, the precipitated HPNA and sediment dissolved and were no longer visible.

Embodiment 3

[0102] A 9.5 g sample of the recycle stream from the hydrocracking unit was mixed with 17.7 g of n-pentane solvent to precipitate HPNA. A precipitate of HPNA can be seen. To this suspension was added 85.0 g sample of aromatic solvent from the aromatic bottoms stream of the aromatics recovery complex. Addition of aromatic solvent dissolved the HPNA precipitate and prevented further precipitation of HPNA.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com