Sensor free heated hose

A hose, heating element technology, applied in the case of the overall content,

Background technique

In this area, problems such as application failure, product invalid application, etc. can be solved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

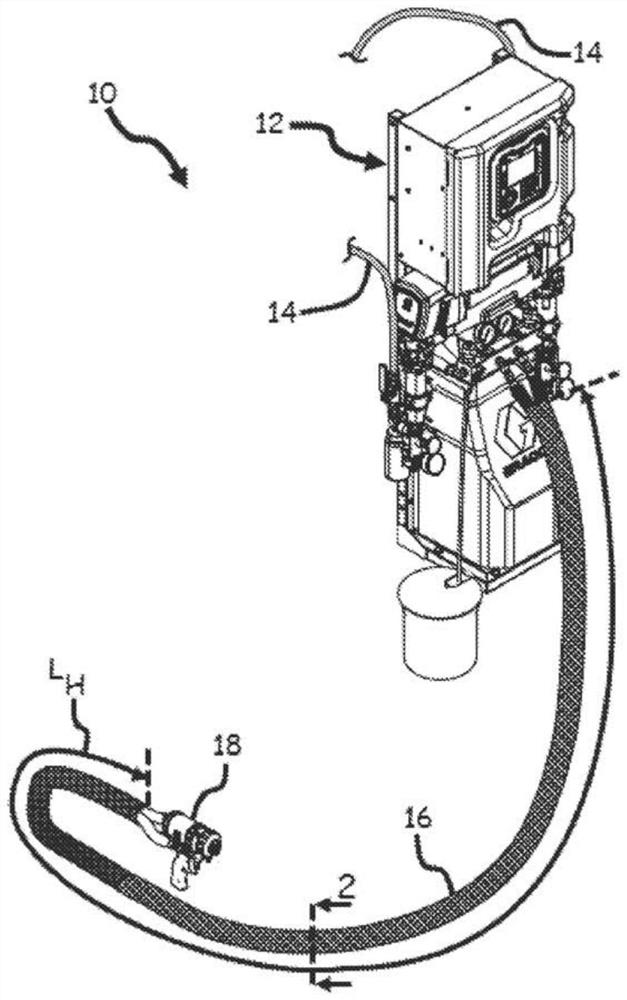

[0013] figure 1 It is a perspective view of a fluid dispensing system 10, and illustrates the control unit 12, supply line 14, hose 16 (having a length L H ) And the spray gun 18.

[0014] System 10 is a fluid management system. In this example, the system 10 is a system for spraying polyurethane foam and polyurea coatings. The control unit 12 is a module for controlling fluid flow through the system 10. In this example, the control unit 12 is a multi-component proportional regulator. In one non-limiting embodiment, the control unit 12 may include a power supply, temperature sensors, resistive sensors, amperometric, fluid compressor, motor and / or the fluid supply tank. Supply line 14 and hose 16 is in the form of an elongated tube fluid hose. In this example, the hose 16 is heated hose. Length L H 16 is the length of the hose. Lance 18 is configured to control the fluid output from the accessory hose 16.

[0015] Supply line 14 is attached to and fluidly connected to the contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com