Fermentation method for removing peculiar smell of tobacco leaves of sun-cured tobacco and application of tobacco leaves in heated cigarettes

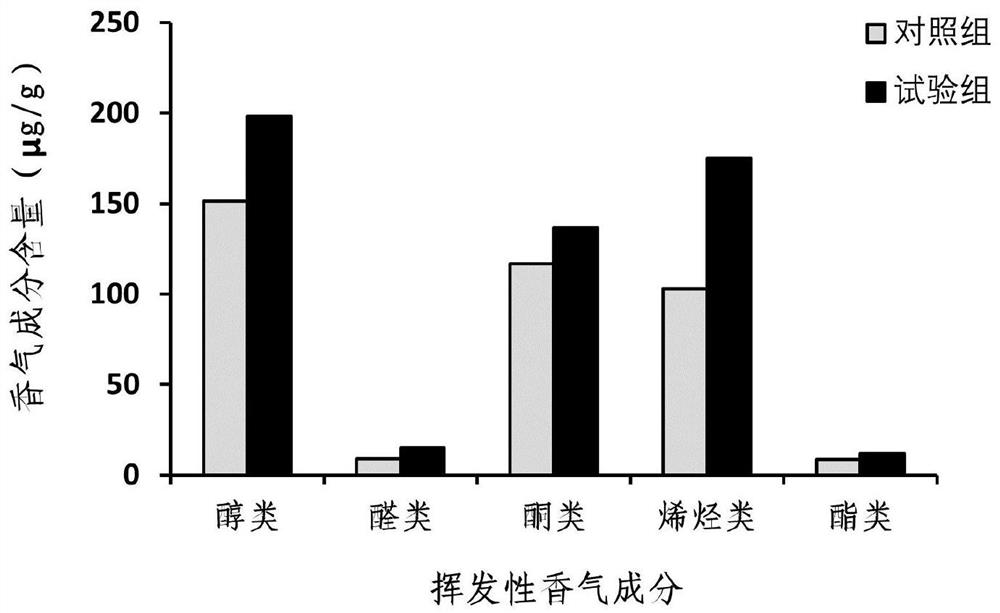

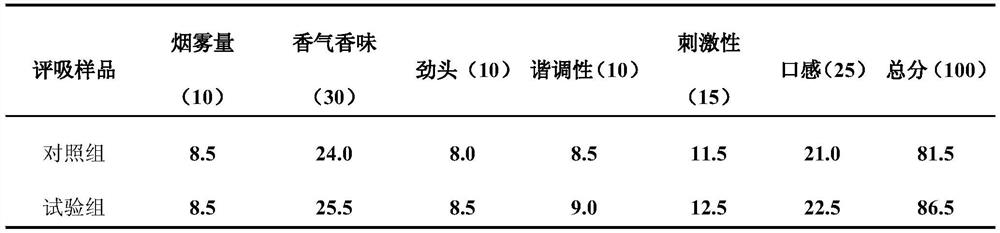

A fermentation method and technology of tobacco leaves, which are applied in the field of fermentation methods and tobacco leaves in heated cigarettes, can solve the problems of heavy odor of tobacco leaves and excessive moldy smoke, and achieve the effect of improving sensory quality, pure smoke taste, and improving sensory quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] This embodiment provides a fermentation method for removing the peculiar smell of raw tobacco leaves of heated cigarette soil tobacco. The selected soil tobacco is Pu'er Zhenyuan Jiujia soil tobacco leaves, which includes the following steps:

[0023] (1) Clean the site of the smoke shed, wash it with clean water, and after drying, spread a piece of clean and odorless white plastic film 10 meters long and 3 meters wide. The tobacco shed site is exclusive and not used for other purposes. The venue is spacious, clean and odorless.

[0024] (2) 100kg of soil tobacco leaves to be bundled are sorted by type after modulation, and spread on the plastic film that has been laid. The tile thickness is 5cm, which is conducive to evenly spraying edible liquor.

[0025] (3) Use a 1kg portable watering can to fill 100mL of 55-degree edible liquor, and evenly spray the petiole of the upper soil tobacco leaf. After spraying, turn the soil tobacco that has not been sprayed on the edib...

Embodiment 2

[0042] This embodiment provides a fermentation method that can be used to treat soil tobacco leaves with peculiar smell and mold, and obtain soil tobacco leaves with odor removal, aroma and sensory quality improvement, including the following steps:

[0043] (1) Pour 200mL of 55% edible liquor into a clean and odorless plastic washbasin with a diameter of 30cm and a height of 8cm under the cleaned smoke shed.

[0044] (2) 5.2 kg of soil tobacco purchased from the market with a certain peculiar smell and a small amount of mold on the petiole was removed from the packaging film and rope, shaken off, and 0.08 kg of soil tobacco that had deteriorated in tobacco leaves was removed.

[0045] (3) Take the remaining 5.12 kg of Tuyan tobacco leaves in bundles of 25 pieces, tidy up the petioles respectively, insert the petioles into a plastic washbasin filled with 55-degree edible liquor, and let the petioles dip in the liquor for 15 seconds.

[0046] (4) Take out the tobacco leaves dippe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com