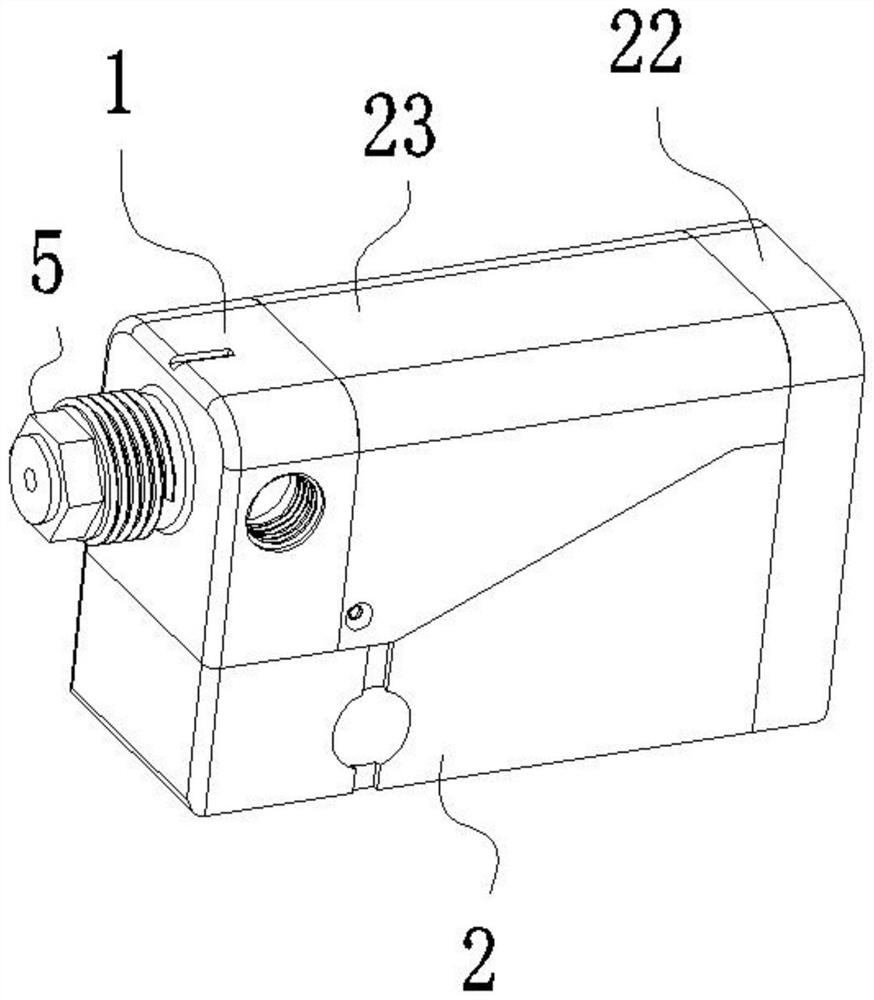

Airless automatic spray gun employing electromagnet to drive switch-on and switch-off movements

A technology of automatic spray guns and electromagnets, applied in spraying devices, liquid spraying devices, etc., can solve problems such as limited space for platform carrying equipment, flammable and explosive high-pressure gas sources, and difficulties in obtaining high-pressure gas sources, achieving outstanding economy, The effect of outstanding practicability and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

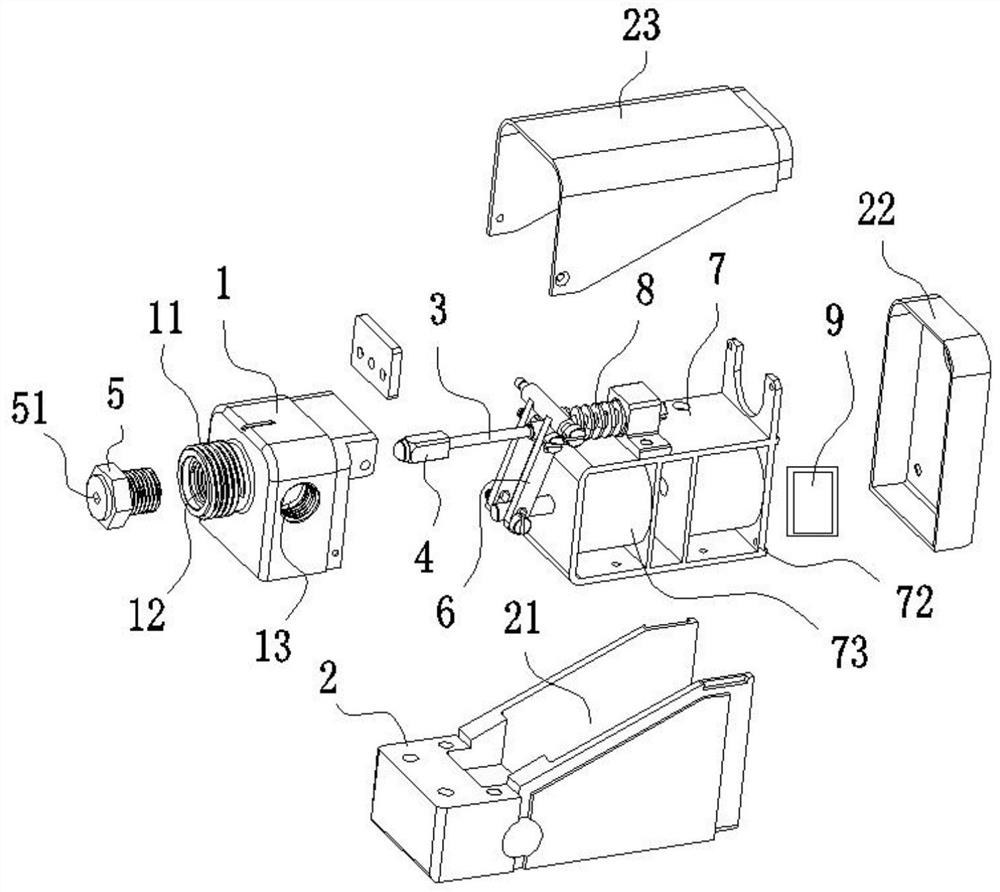

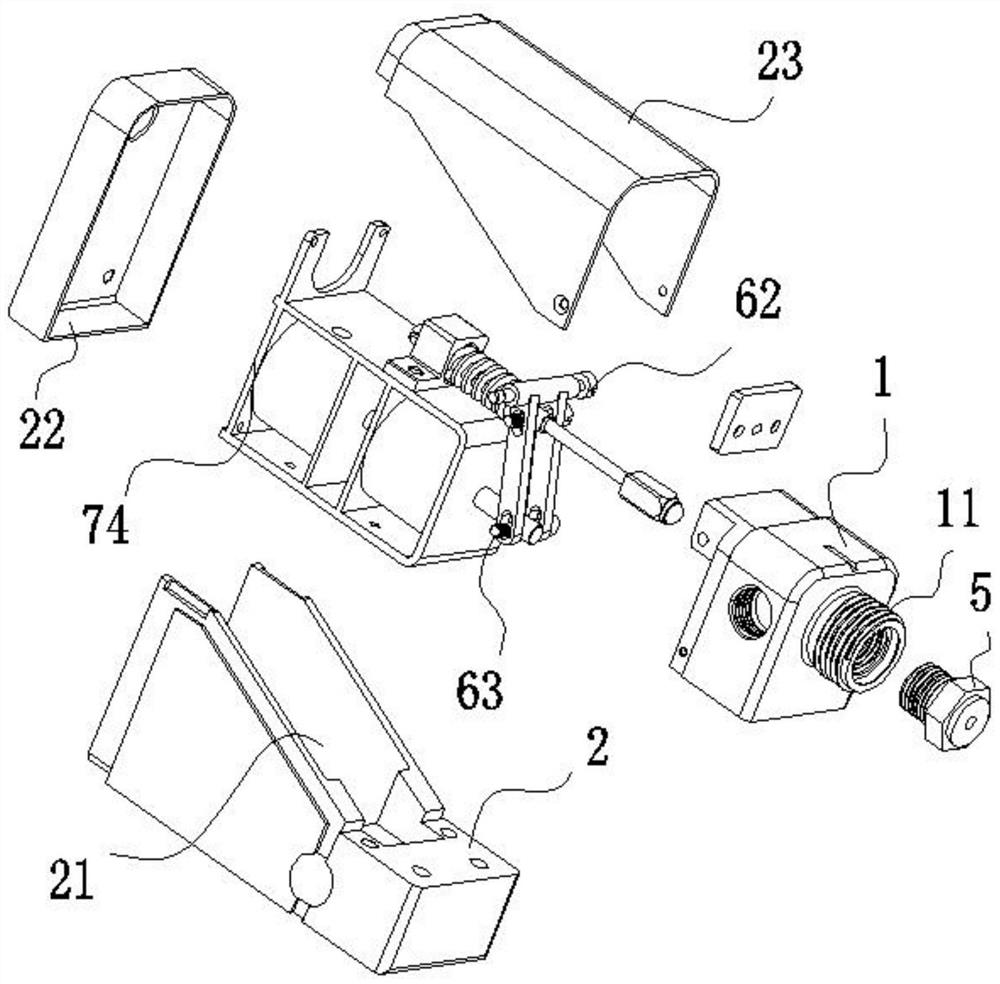

[0024] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals represent the same or similar elements or elements having the same or similar functions throughout.

[0025] The orientations shown in the drawings should not be construed as limiting the specific protection scope of the present invention, but are only for reference and understanding of preferred embodiments, and the product components shown in the drawings can be changed in position or increased in number or simplified in structure.

[0026] The "connection" described in the specification and the "connection" relationship between the parts shown in the drawings can be understood as fixed connection or detachable connection or integral connection; it can be directly connected or connected through an intermediary. Those of ordinary skill in the art can understand the connection relationship according to the specifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com