Circulating temperature-controlled microalgae illumination culture device

A technology of light cultivation and cyclic temperature control, which is applied in enzymology/microbiology devices, biochemical cleaning devices, photobioreactors, etc. The effect of sufficient strength, simple operation and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the above-mentioned design and features of the present invention more obvious and understandable, and to make the technical solution of the present invention clearer to those skilled in the relevant art, the exemplary embodiments of the present disclosure will be described in more detail below with reference to the accompanying drawings, but the implementation of the present invention alone does not Limited to the examples set forth below.

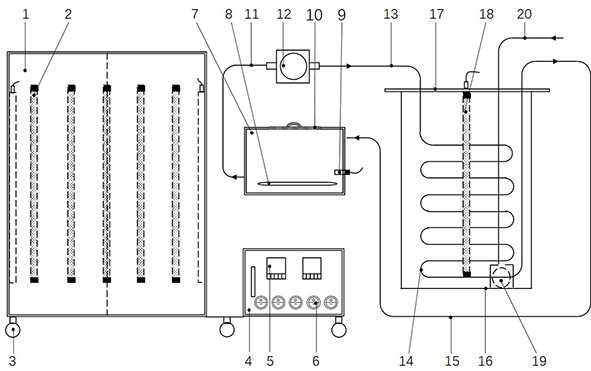

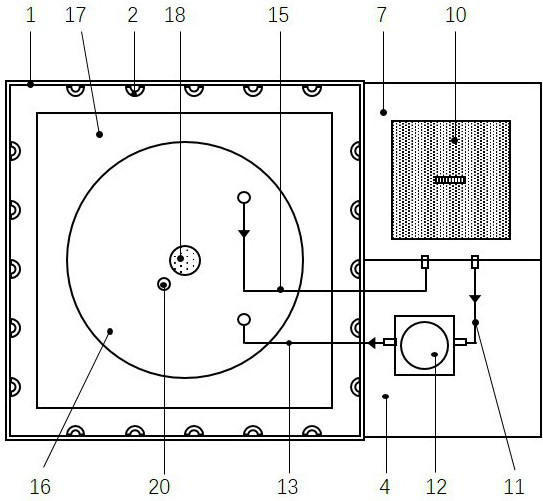

[0019] Specifically, as figure 1 Shown is a schematic structural diagram of a cycle temperature-controlled microalgae light culture device in an embodiment of the present invention, which is mainly divided into two parts: a culture system and a temperature control system. The cultivation system includes a light box and a culture vessel. Five fluorescent tubes are installed on each side of the light box. The front is a door structure that can be opened and closed, which is convenient for taking and placing the cultur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com