Fixing method of concrete drainage ditch expansion joint foam board

A fixing method and technology of foam boards, which are applied to drainage structures, waterway systems, water supply devices, etc., can solve problems such as difficulties, small rigidity of foam boards, deviation of drainage ditches, etc., so as to save construction period, enhance leakage resistance, reduce The effect of engineering costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

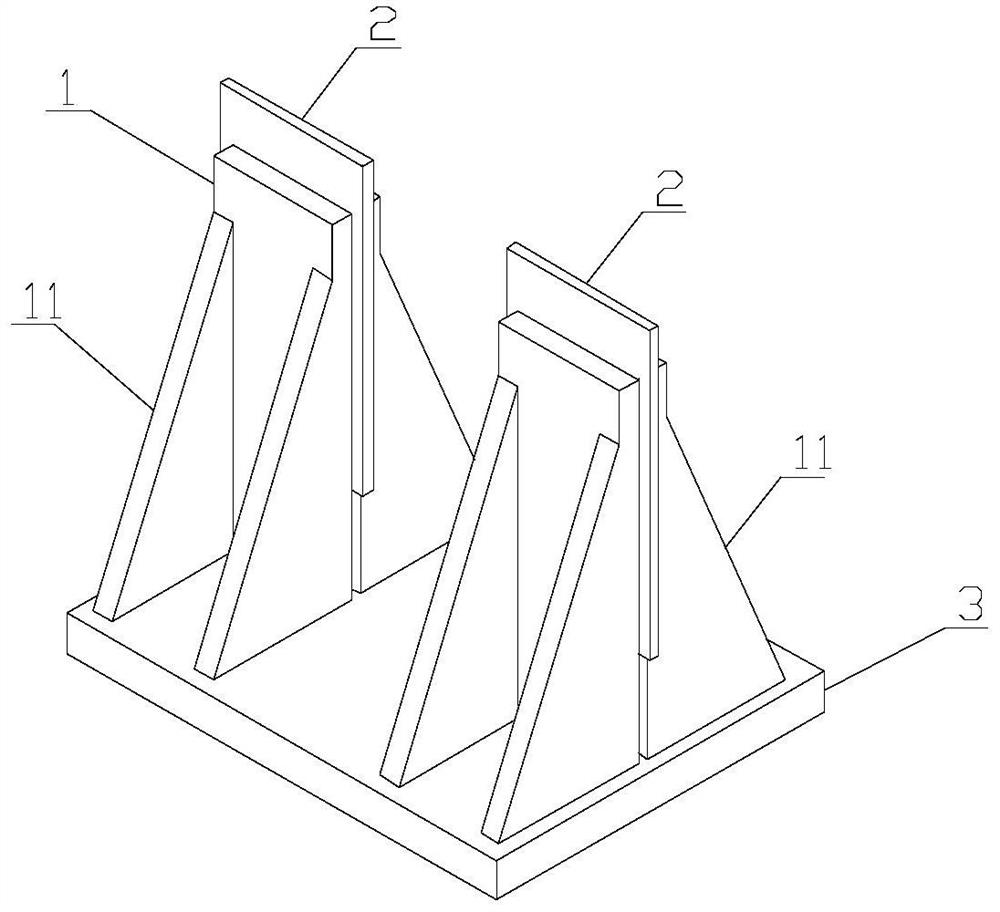

[0020] refer to figure 1 , figure 2 , image 3 and Figure 4 , a method for fixing foam boards in expansion joints of concrete drains, comprising the following steps:

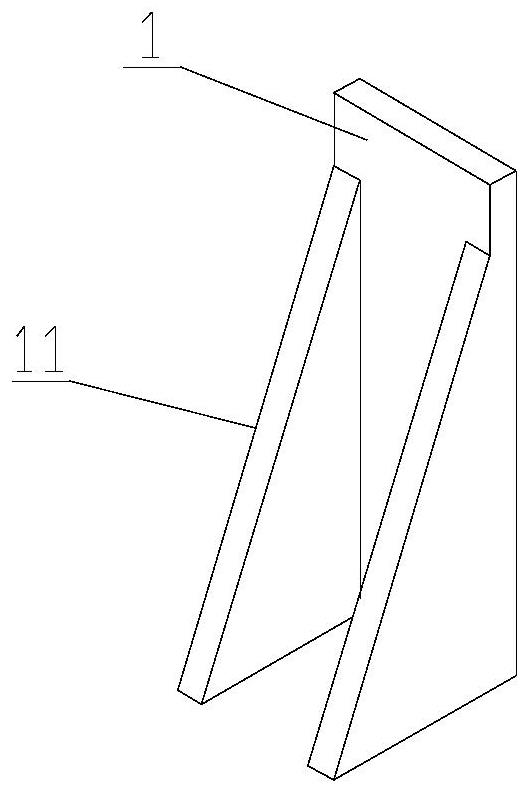

[0021] Step 1. Make the foam board fixing frame (such as figure 1 ), using cement mortar for prefabrication, which includes a rectangular panel 1, the width of which is slightly smaller than the width of foam board 2, and the longitudinal sides of the back of rectangular panel 1 are respectively provided with triangular ribs 11, using a special trial mold Overall prefabrication.

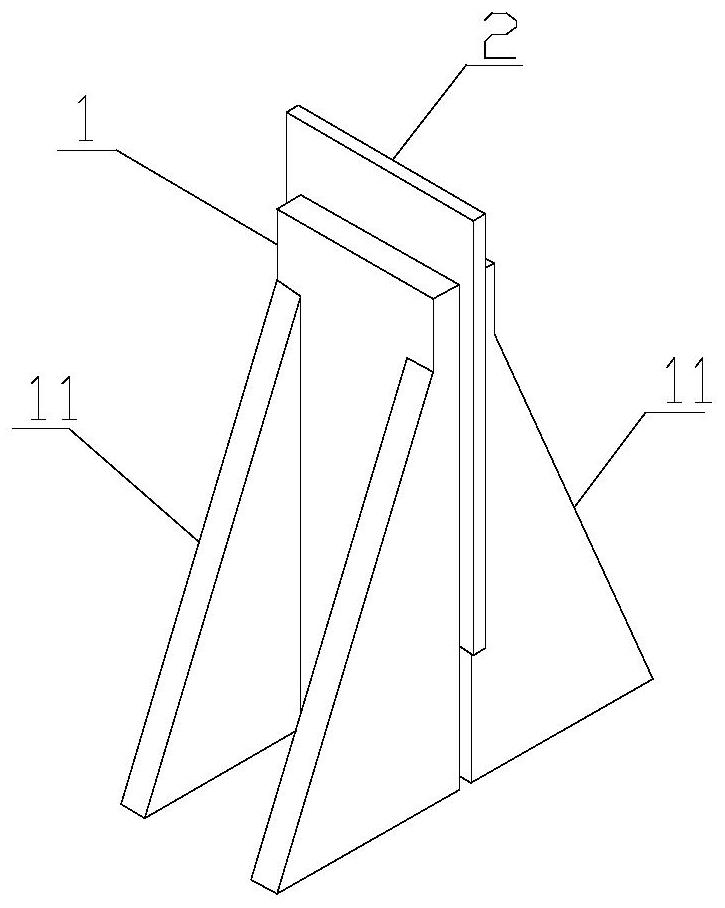

[0022] Step 2. Place the two foam board holders in step 1 upright and facing each other, apply glue on the front and back of the foam board 2, and then put it between the two foam board holders. The upper side of the foam board 2 is higher than the rectangle The panel is 100 mm away from the bottom edge of the rectangular panel 1 by 200 mm, so that the front of the rectangular panel 1 touches the foam board 2 and is fixed with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com