Coal-pillar-free self-roadway-forming balanced mining method and equipment

A mining method and technology without coal pillars, applied in mining equipment, ground mining, installation of bolts, etc., can solve problems such as unbalanced force, support system failure, roadway instability, etc., and achieve the effect of avoiding uneven settlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

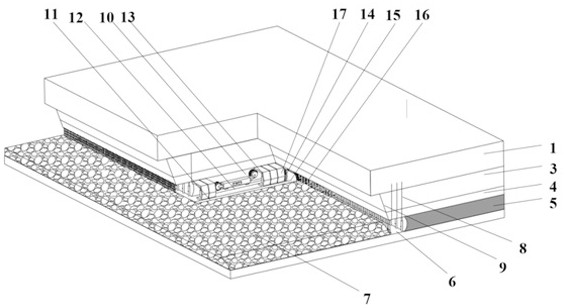

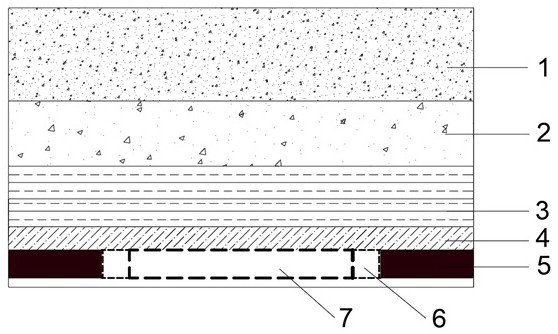

[0044] Preferred embodiments of the present invention are described below with reference to the accompanying drawings. Those skilled in the art should understand that these embodiments are only used to explain the technical principles of the present invention, and are not intended to limit the protection scope of the present invention.

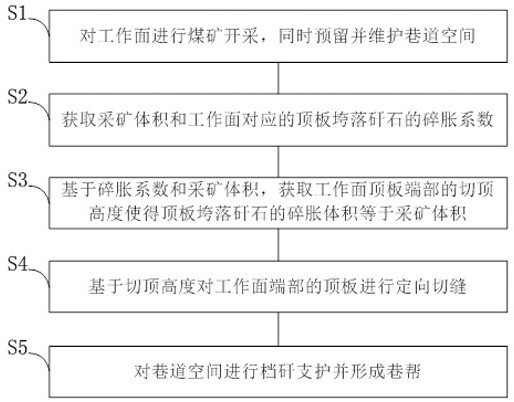

[0045] The design principle of the balanced mining method and equipment provided by the present invention is: according to the roof movement characteristics after mining, the mining damage invariant equation is established K 1 + K 2 + K 3 =1, from the perspective of mining rock mechanics, analyze the rock formation damage produced in each stage of the mining process, and control the balance between the crushed volume of the roof collapsed gangue and the mining volume, that is, △V B =△ V m , K 3 =1, substituting into the mining damage invariant equation, we can get K 1 and K 2 Both are 0, and the mining damage invariant equation ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com