Nozzle for hot drying of waste paint bucket

A thermal drying and nozzle technology, applied in drying, dryer, drying gas arrangement and other directions, can solve the problems of inability to perform rapid automation, inability to quickly automate drying, complicated operation process, etc., and achieve fast and efficient drying, Simple structure and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

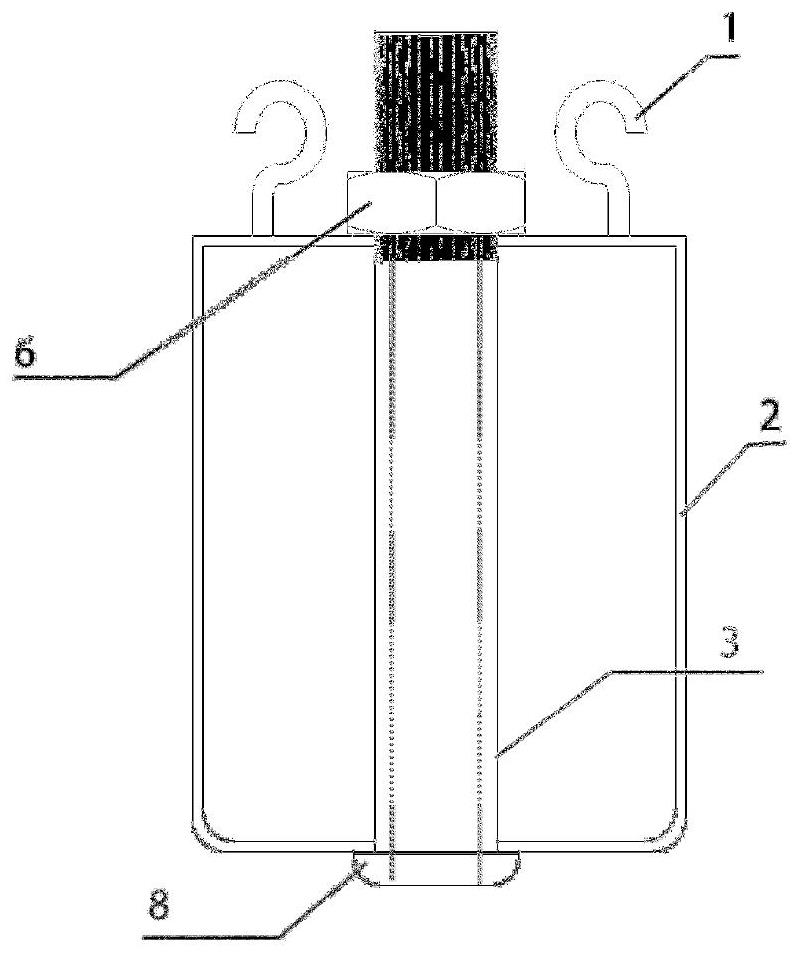

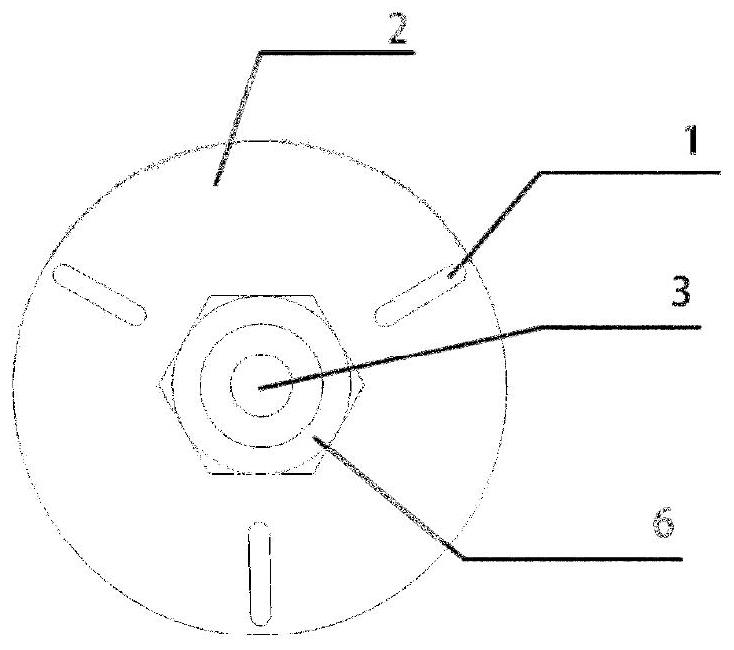

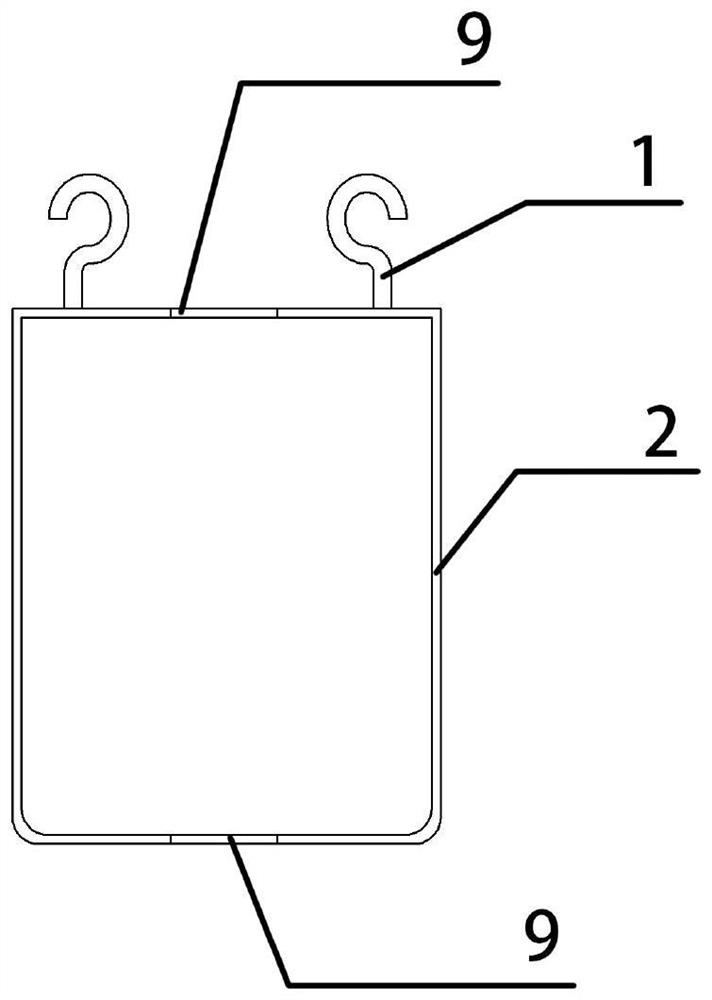

[0024] See attached Figure 5 The lifting ring 1 adopts manual machinery or automatic machinery to lift the present invention, and places it in the fixed waste paint bucket 10. The distance between the baffle shell 2 and the inner wall of the waste paint bucket 10 is 85mm, and the bottom distance is at least 100mm. Connect the air pipe 11 above the central hole air channel 3 with the external thread 7 to form a whole through a fixed heat source. Subsequently, the waste paint bucket 10 is thermally purged by introducing hot air, hot steam or hot nitrogen.

[0025] See attached Figure 6 , the hot gas introduced from the gas injection port below the central hole air channel 3 fills the bottom of the waste paint bucket 10, and flows out quickly along the gap 12 between the baffle shell 2 and the waste paint bucket 10, and the waste paint is taken away by evaporation in the process The volatile substances on the surface of the inner wall of the barrel 10 finally complete the rap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com