Folding property detection system for high-performance concrete

A high-performance concrete and detection system technology, applied in the direction of using stable bending force to test material strength, using stable tension/pressure to test material strength, measuring device, etc., can solve the problem that the concrete block cannot be fixed and affect the test effect. , reduce the accuracy of the test, etc., to ensure the effect of the compression test, improve the convenience, and improve the applicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

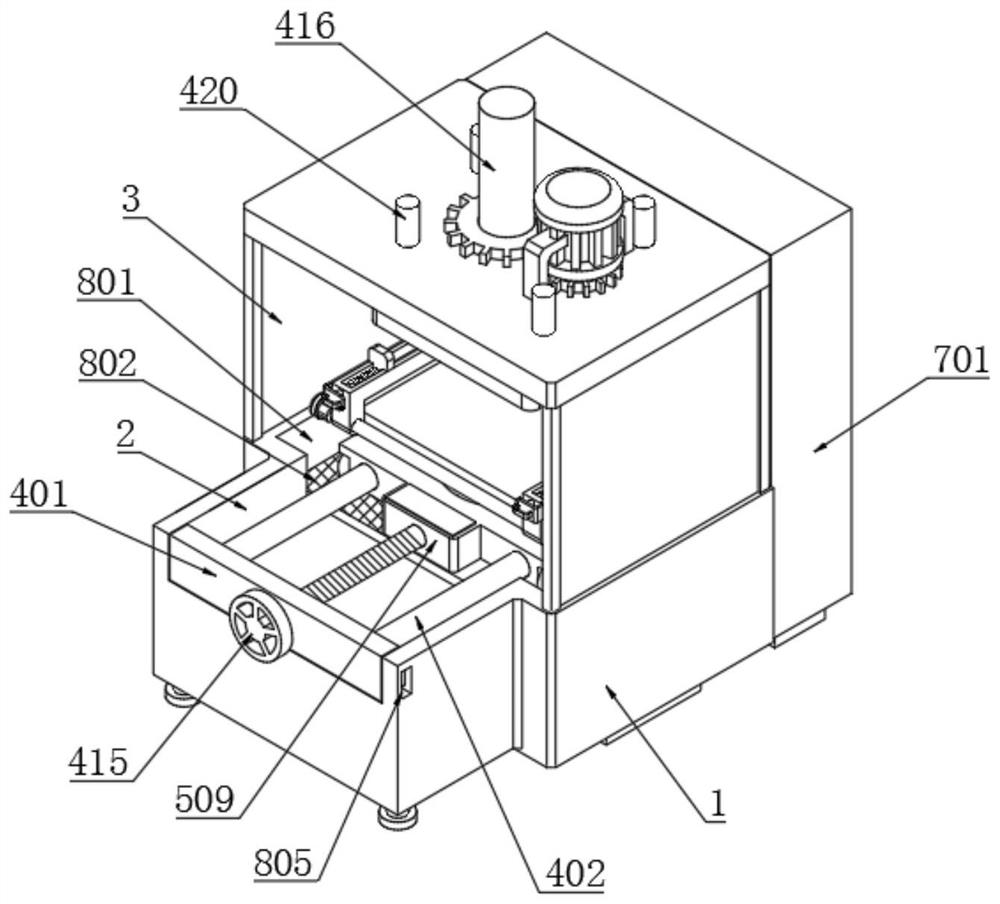

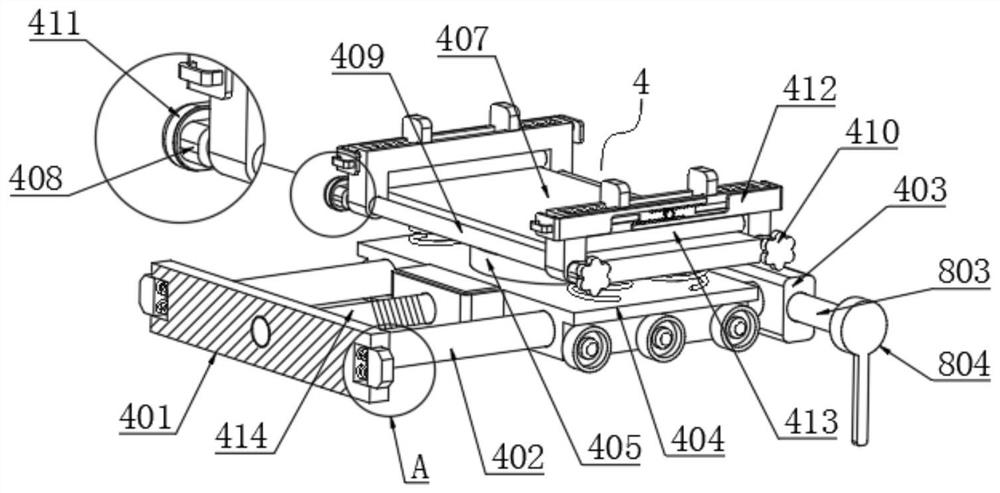

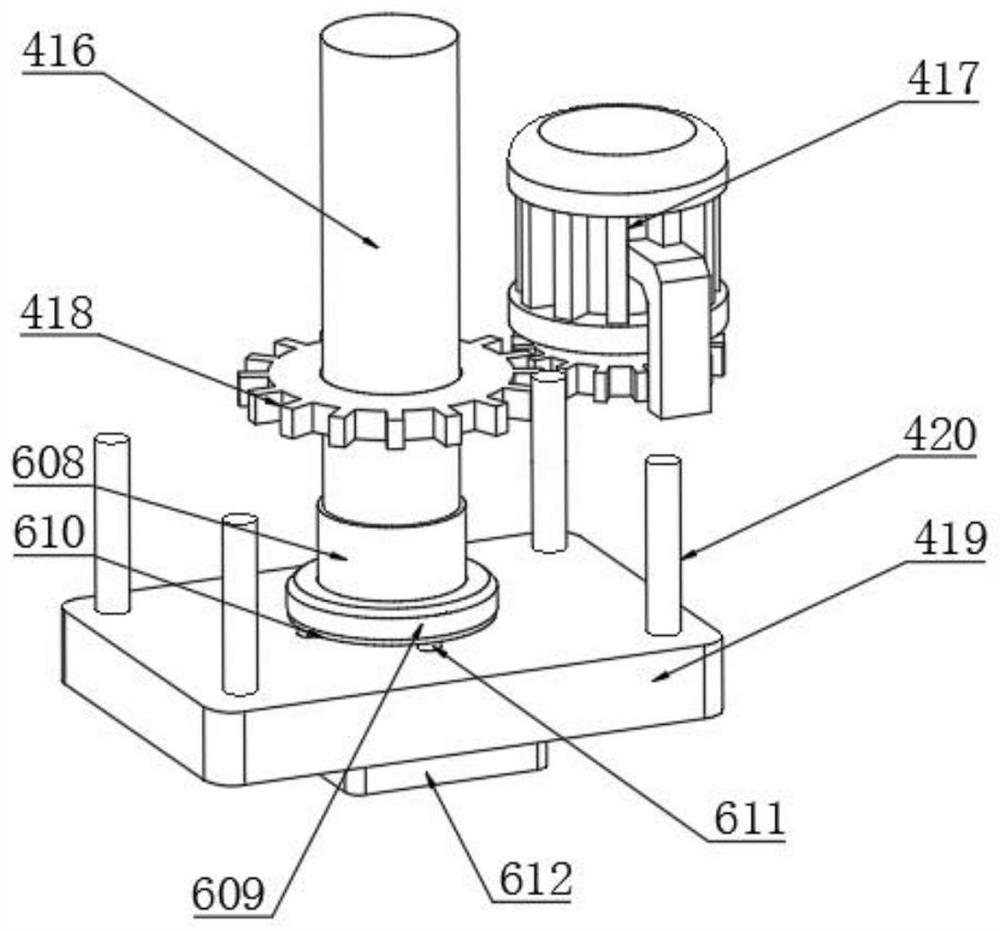

[0031] Example: such as Figure 1-7 As shown, the present invention provides a high-performance concrete foldability detection system technical solution, including a base 1, the top of the base 1 is provided with a notch 2, and the top of the base 1 is fixedly connected with a protective cover 3, and the inside of the notch 2 is provided with a positioning The adjustment mechanism 4, the positioning adjustment mechanism 4 includes a fixed plate 401, a limit rod 402, a rotary block 403, a mobile platform 404, a sleeve 405, a pillar 406, a placement plate 407, a bump 408, a screw rod 409, a knob 410, and a belt 411 , support plate 412, support roller 413, screw rod 414, turntable 415, pressure bar 416, rotating motor 417, transmission gear 418, pressure plate 419, slide bar 420 and transmission shaft 421;

[0032] One side of the inner wall of the notch 2 is movably connected with a fixed plate 401, one end of the fixed plate 401 is symmetrically fixedly connected with a limit r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com