Sintering machine lubricating method based on multi-position monitoring air leakage points

A technology for sintering machines and air leakage points, which is applied in the field of sintering, can solve the problems of not being able to intelligently monitor the air leakage intensity of air leakage points, the air leakage rate is not significantly reduced, and the frequency of refueling is changed, so as to save manpower, improve sintering quality, and reduce air leakage rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

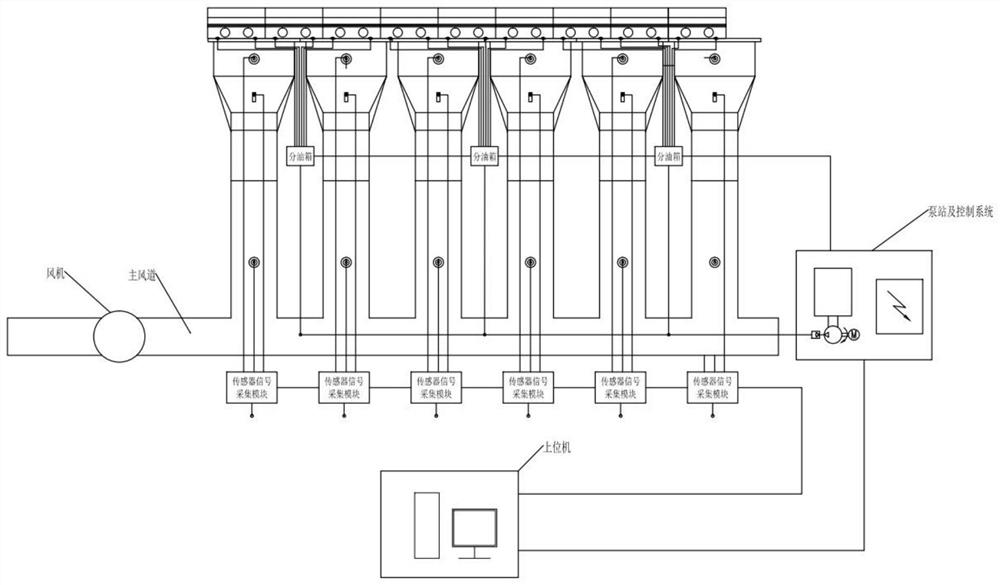

[0042] A sintering machine lubrication method based on multi-position monitoring of air leakage points, such as figure 1 As shown, it includes a sintering system, a sensor signal acquisition module, a data processing module, and an intelligent lubrication system. The data module is carried out in the host computer, and the intelligent lubrication system includes a pump station and a control system.

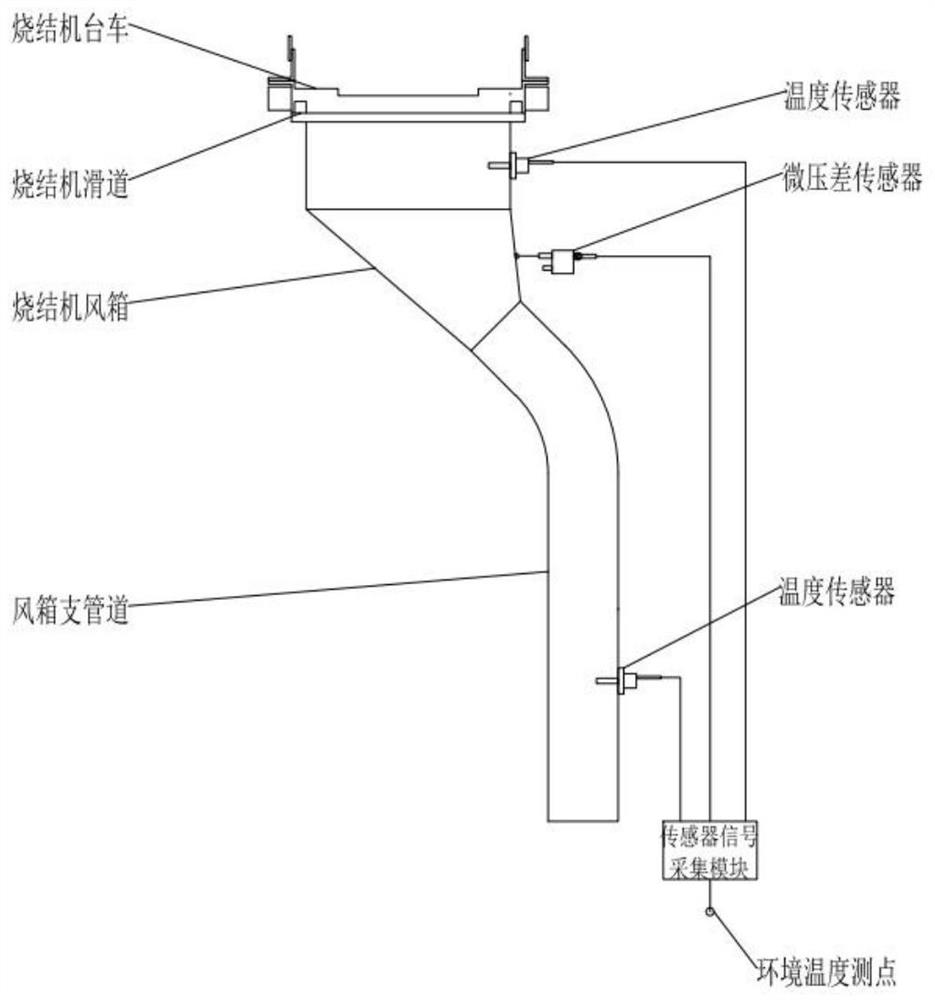

[0043] Taking a bellows as an example, such as figure 2 As shown, the sintering system includes trolleys, slides, bellows, and bellows branch pipes. The sensor signal acquisition module includes temperature sensors and micro-pressure difference sensors. The specific installation positions are as follows: figure 2 shown.

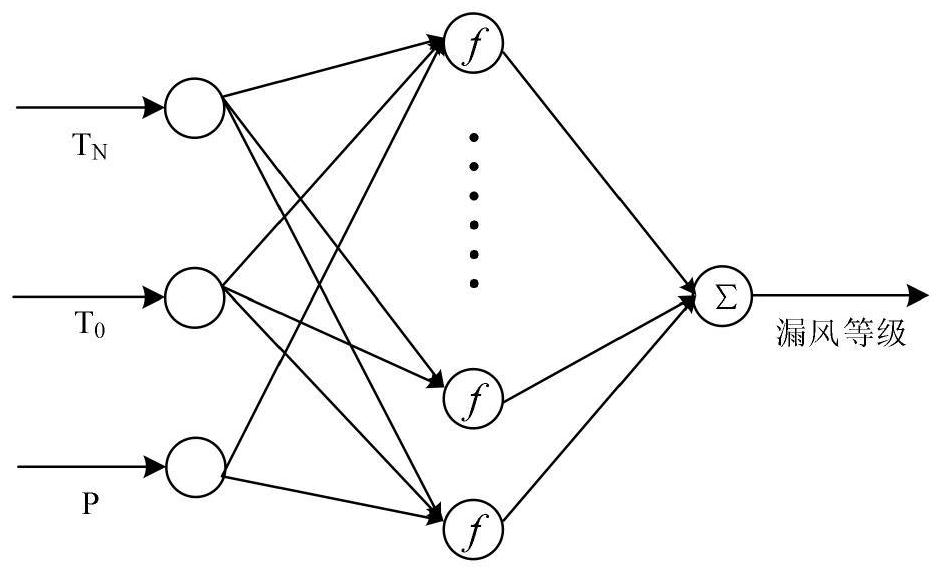

[0044] Through the sensor signal acquisition module, the ambient temperature T is collected in real time 0 , temperature T at the seam of the bellows trolley N , the data of the differential pressure P, and interact with the server for data processing throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com