Online intelligent sintering air leakage monitoring method based on big data

An intelligent monitoring and big data technology, applied in furnaces, furnace types, lighting and heating equipment, etc., can solve the problems of inability to real-time online measurement, low intelligence, and high detection costs, achieving low cost, accurate calculation results, and air leakage. rate accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

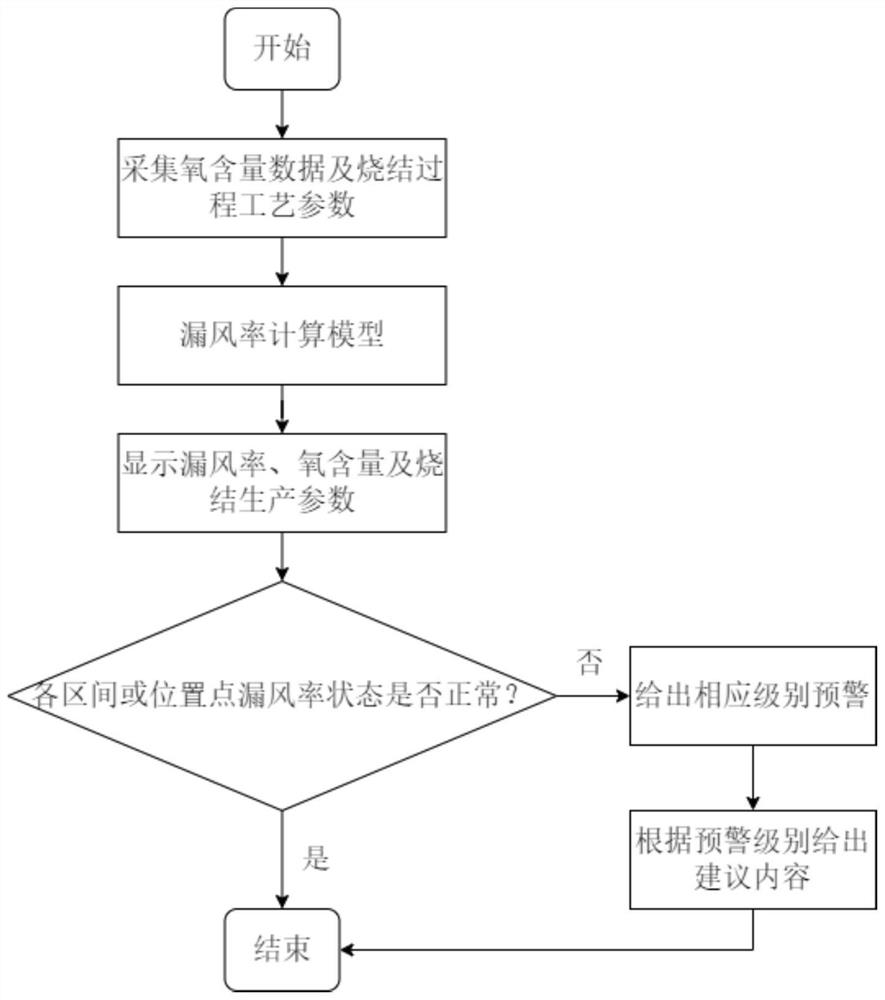

[0066] like figure 1 As shown in the figure, in this embodiment, an online intelligent monitoring method for sintering air leakage based on big data of the present invention is used to monitor sintering air leakage, and the main steps are as follows:

[0067] (1) Collect oxygen content data and process parameters of sintering process

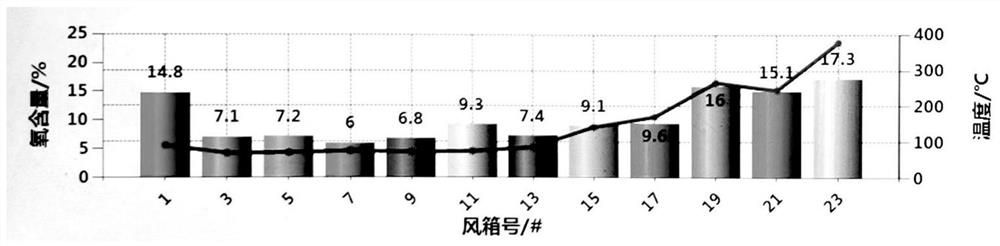

[0068] The oxygen content data of the flue gas in the sintering machine bellows and before and after dedusting by the electrostatic precipitator were collected by using a zirconia oxygen meter, and the temperature data of the flue gas inside the bellows was collected by using a thermocouple sensor. After that, the collected data is transmitted to the PLC, and then based on the OPC technology, the PC and the PLC can establish communication, and the acquired real-time data is transmitted to the PC.

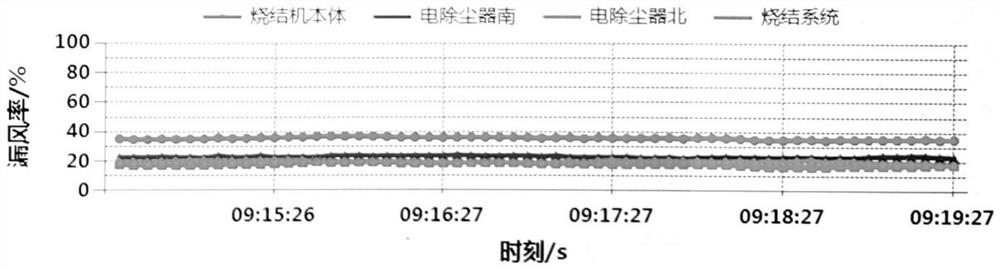

[0069] (2) Real-time data display and air leakage rate calculation model

[0070] After the real-time data is obtained, it is sent into the air lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com