Probability fatigue life prediction method coupling gap and size effect

A technology for fatigue life prediction and size effect, applied in special data processing applications, instruments, electrical and digital data processing, etc., can solve problems such as conservative and difficult parameter acquisition, and achieve strong universality, simple solution, and model prediction accuracy. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to facilitate those skilled in the art to understand the technical content of the present invention, the content of the present invention will be further explained below in conjunction with the accompanying drawings.

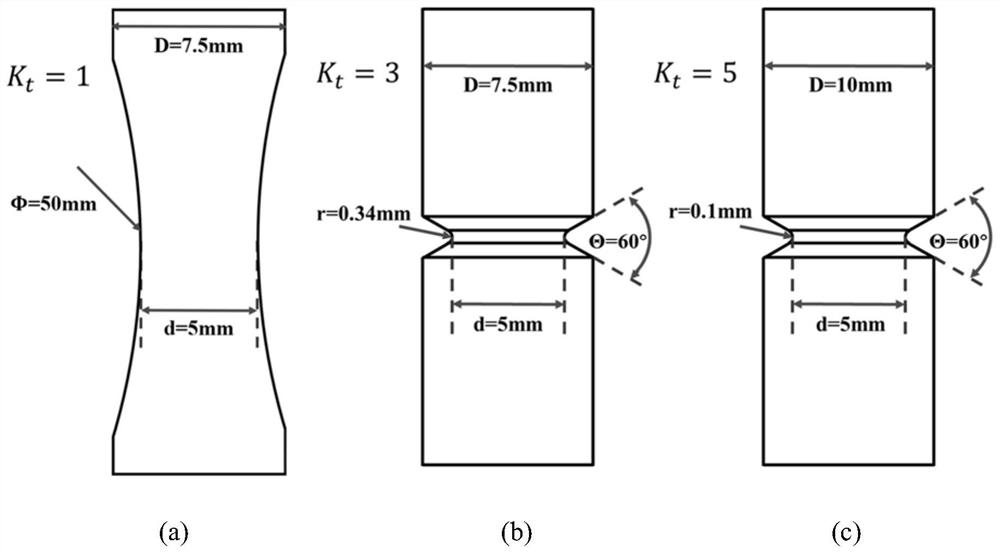

[0046] The present invention verifies the proposed life prediction method through the TC4 material fatigue test data, specifically including the theoretical stress concentration factor K t = 1, 3, 5 fatigue specimens, the corresponding specimen size is as follows figure 1 , where (a) is the stress concentration factor K t = 1 smooth specimen size, (b) is the stress concentration factor K t =3 for the size of the notched specimen, (c) is the stress concentration factor K t =5 notched specimen size. figure 1D is the diameter of the clamping section of the sample, d is the diameter of the gauge section of the sample, r is the radius of the notch, Θ is the opening angle of the notch, and Φ is the arc radius of the gauge section of the smooth sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com