High-voltage vacuum relay

A vacuum relay, high-voltage technology, applied in high-voltage air circuit breakers, high-voltage/high-current switches, circuits, etc., can solve the problems of low insulation performance and inability to meet, and achieve the effects of good insulation performance, safe use, and not easy to wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

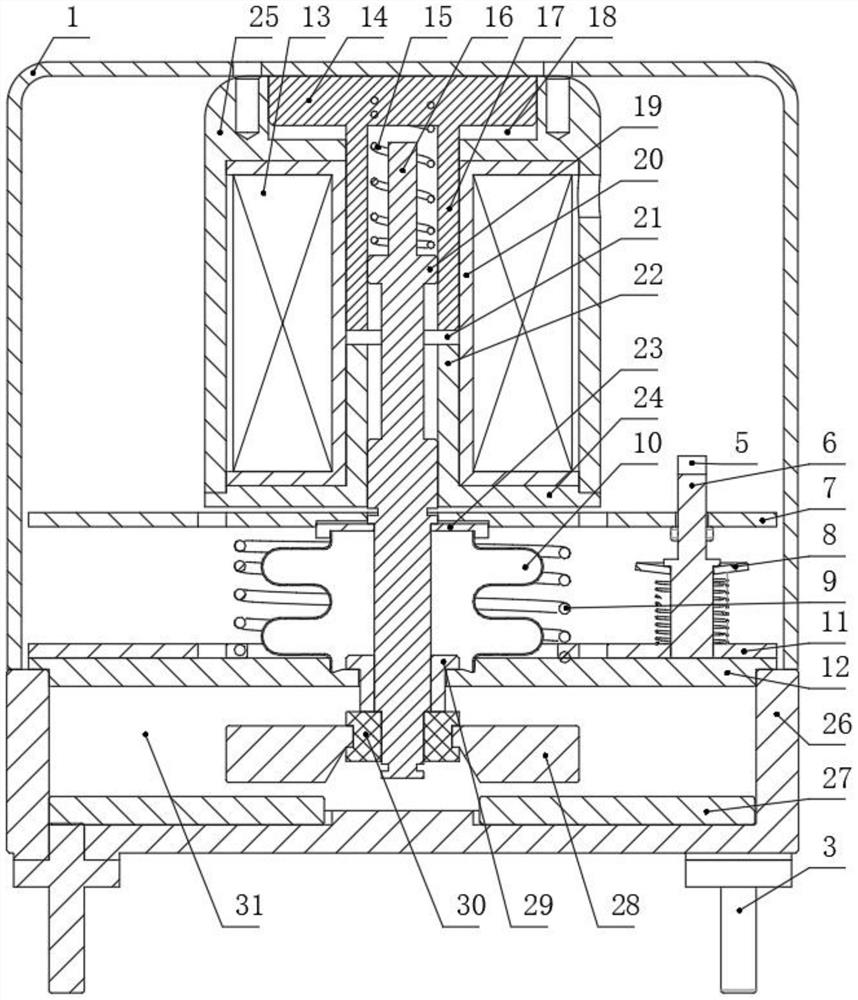

[0019] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

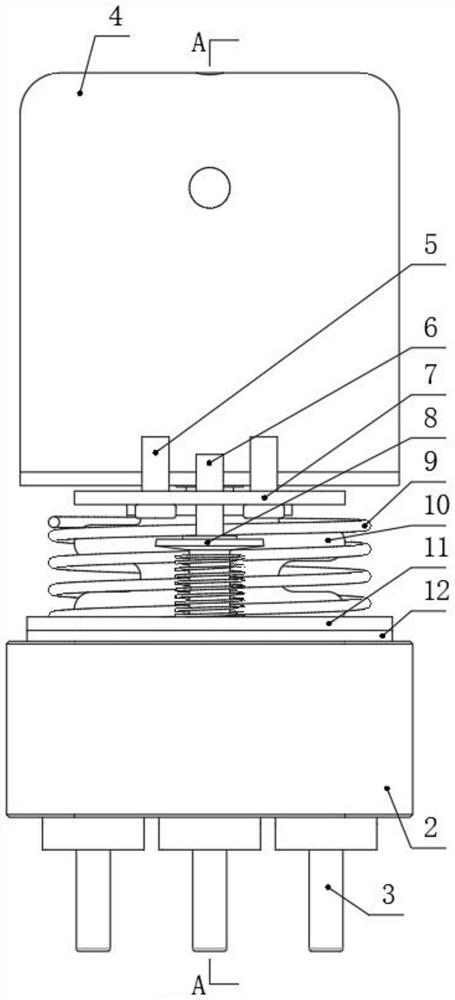

[0020] A high voltage vacuum relay, such as Figure 1-3 As shown, the innovation of the present invention lies in: comprising upper sleeve 1, vacuum chamber 2 and magnetic drive mechanism, the upper end of described vacuum chamber is provided with upper sleeve, and the magnetic drive mechanism is set in the upper sleeve, the sliding in the magnetic drive mechanism A moving contact 28 is provided at the lower end of the component 16 sealed and protruding into the vacuum chamber, and a static contact 27 aligned with the moving contact is arranged in the vacuum chamber, and the static contact is connected to the terminal 3 provided on the surface of the vacuum chamber.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com